Monovspring is a type of electronic injection system. Served as a transition model on the way from the carburetor to the injector.

The first was designed for the aircraft as an alternative to a carburetor and a means to combat power outages in the execution of a "dead loop" and other aerobatic maneuver figures

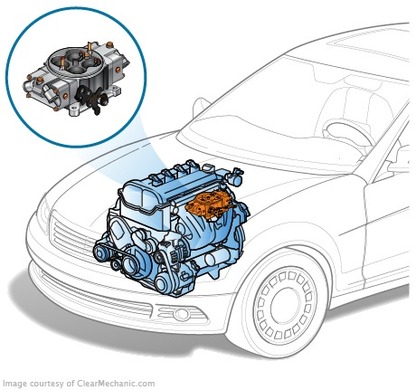

In essence, a monopnod is an advanced carburetor with a microprocessor-controlled fuel supply and one injector.

History of Mozop

The traditional mechanical carburettor used to feed the internal combustion engine since 1893 has become the basis for the development of the monovspring system. The most serious difficulties with carburettors were raised by pilots, as the jet fuel delivery provided in the carburettor made it extremely difficult to perform the maneuvers that implied the 90-or 180-degree coupe. In this situation, the disruption of the fuel supply was inevitable.

The first injection of a mechanical mono can be considered as a fuel injection system under pressure, which was equipped with a 1916 aircraft engine of the Russian designers Stechkin and Mikulin. The system was considered successful, and during the Second World Devices of this type were equipped, for example, the aircraft engines Daimler-Benz and BMW.

The purchase of a used car with a monsoon in the late ' 90s was frail for Russian car enthusiasts-it was almost impossible to find a master for their repair

Ordinary carburettors have been in the automotive industry for much longer, as the need to change the position of the engine relative to the horizon has never occurred. Therefore, this electronic-controlled monopryl was introduced only in the 1970s, when the problem of fuel economy was raised in front of car manufacturers. Japanese manufacturers (for example, Honda with PGM-Carb) and the US GM (GM system Multec Central) were pioneers of the introduction of monoplance. During the same period, the first relatively cheap microprocessors, which allowed the creation of electronic injector systems on the basis of carburettors, had a huge advantage-simplicity of configuration and stability of work. In the future, single-ore systems, which were only the transition steps between the carburettor and the injection system, disappeared from the market due to technical imperfection.

Device and principle of monopasco

The monovborne is a substantially modified carburettor, which is different from the classical presence of computer control of the fuel supply and consumption, the electric nozzle and the gas pump. A classic carburetor has inherited a lot-an enclosure, a point of anchorage to the engine, a system of cameras and peripheral devices (engine and tp system). Unlike the delivery system, the fuel pressure of the engine with a mono fuel is maintained at a constant relatively high fuel pressure (usually in the area of 1 bar). The electrical fuel pump shall be used to create the pressure. To maintain the pressure regulator. Just as in the injection systems, through the nozzle, there is exactly as much fuel as is needed for the single filling of the combustion chamber, and the surplus is returned to the fuel tank under the reverse feed system.

The development of the monolyzk has become a logical extension of the carburettors ' improvement. The last generation of Hitachi carburettors has already been equipped with electronic control units

It is noteworthy that the fuel delivery scheme used in the combustion chamber, which used the features of the carburetor, was used in the monovryl. If the spray nozzle is sprayed in the intake manifold cavity, the injection of the fuel with air takes place inside the classic carburettor, and then the mixture is drawn into the collector, and then into the combustion chamber.

In fact, the electronic control unit controls only the fuel dosing process. On the signal from the throttle position, the lambda probe, the inlet temperature sensor, and the flow-meter, it calculates the required quantity and submits the command to the opening of the nozzle. The duration of the opening period, and therefore the required dose, is also calculated from the signals from the sensors. The higher the engine speed, the longer the open nozzle remains.

Advantage and shortcomings of the monopasco

With the advent of the monsoon, it has become much better to work in the transition modes-during acceleration and braking, that is, when there is a significant change in turnover. Previously, in carburetor systems, the problem was solved more or less successfully, but the reaction of the engine to the sharp opening of the throttle was always slow. Monovhim helped solve the problem and a number of others. For example, the first efficient catalyst-based exhaust systems have appeared, as the lambda-probes that measure the balance of oxygen in the exhaust have come together with the electronic control of the injection system.

However, there were significant deficiencies in the monovoll. The biggest weakness of the system is fuel injection at one point. As a result, some of the fuel was settled on the walls of the intake manifold where the dust was spread and the mixing with air was not efficient enough. During the winter, the car could have been poorly zled for this reason, and the fuel economy as a whole, compared to the distributed systems, was not sufficient.

Operation and maintenance of monollek

In the process of operating the system, the only nozzle of the system falls under heavy load. If compared to the current distributed injection per cylinder, it is easy to imagine how much fuel to pass through one injectable compared to four or more. This raises a serious risk of the quarrel, to wash the system, or to repair (change) the injectable is often enough.