History of the installation of a combined boost on engines

The very first combustion engines installed on the internal combustion engines were mechanical. They create pressure at the intake path from idle speed, but there is a significant lack of engine power. Consequently, a perceptive portion of the power is spent on the rotation of the supercharger. It is not effective at high speed, and it significantly increases the fuel consumption.

The turbochargers are soon replaced by the mechanical injection. They turned out to be a much more effective mechanical boost. First, they work from the exhaust, that is, they use the free energy, and secondly, they are compact and quieter. True, the turbochars are inefficient at low speeds when the exhaust gas flow is too weak. And also, the coil has a high level of inertia. I mean, she needs time to spin around. This delay is called "turbo". Although the concept of "turboyama" has been more in Russia.

The first in the history is a real mass motor with a combined supercharged engine of Volkswagen

The problem was partially solved by the appearance of the turbine with variable geometry. That is, depending on the engine speed of the engine, turbine blades may turn about the flow of gas. At low engine speed the blades are almost perpendicular to the energy of the exhaust stream as efficient as possible.

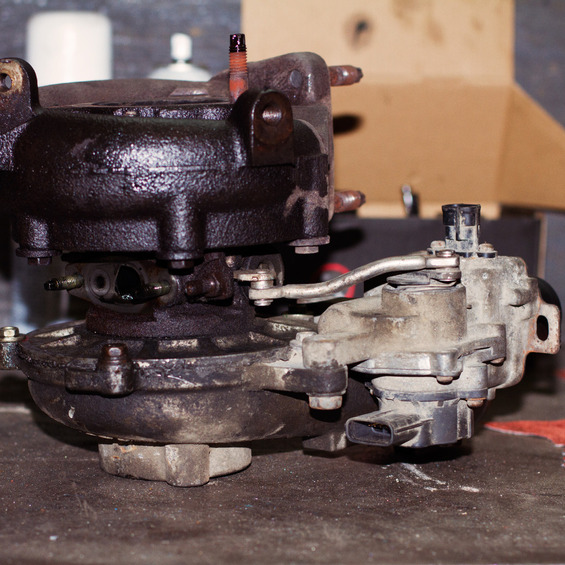

But Volkswagen's engineers went a different way. They offered the customers a motor with a combined boost. The 1.4 TSI engine with a mechanical compressor and turbocharged according to the settings gave up to 178 hp. It was installed on the Skoda, Audi, SEAT, and, in fact, the Volkswagen and was the first in car history to be a real mass motor with a combined boost.

This engine won the title "Engine of the Year" in 2009 and 2010. But in 2011 it was decided to withdraw it from production. The company explained this by the combination of overwork and roads in both production and repair. Therefore, the current 1.4 TSI motors are only equipped with turbocharged.

Device and operating principle of the combined supercharged

The mechanical boost shall be given by the wheel-belt and shall be installed in front of the turbine. It operates at low engine speeds and allows to realize the engine's potential from practically idle speed. When the Tachm passes the mark in 2000, the turbine is connected to the work and up to 3500 they work together.

The unconditional advantage of the combined boost is the absence of a turboyum effect

The electromagnetic muff turns off the compressor when it continues to increase, and the special flap allows the air to bypass the mechanical injection. Thus, the turbine only works on high turnover. In addition, the engineers have set up control electronics in such a way that the attachment or disconnection of a driver remains invisible to the driver and passengers.

Advantage and disadvantages of combined boost

The unconditional advantage of a combined boost is the absence of a turboyum effect. The engine is starting to emit its Newton-meters practically from idle speed. This is not only for lovers of "lighting" with traffic lights, but it also helps to save in traffic jams, helping you to move easily from the spot without having to unwind the engine.

However, there are more negative points. First of all, this is the high cost and complexity of production. If you break it, you'll have to put a lot of money into the car service. A turbine, a mechanical device, an electromagnet coupler, a belt and a patchwork take up a lot of space. This makes maintenance extremely difficult. And even if you need a little repair, you have to take literally half the car.

Operation and maintenance of combined

The turbin-mechanical turbinder is quite reliable and does not require special attention. You only need to be careful when replacing the air filter so that no details are included in the inlet tube. Even a small nut or a screw in a mechanical injection can lead to a breakdown of the expensive aggregate. Repairs in this case are usually inadvisable, cheaper to buy a new one.

The owner of a motor vehicle with a combined charge shall periodically check the belt of the actuator. It should not have any fractures or cracks. It should be replaced by the manufacturer's recommendation or the service that serves your machine. This work can be done in the same way with certain skills and wishes.

The bearings will have to change in the bear-driven vehicle when the bearings are reached. But this work should only be done in a specialized service. The details of this unit are performed with high precision and cannot be trusted to repair the garage.