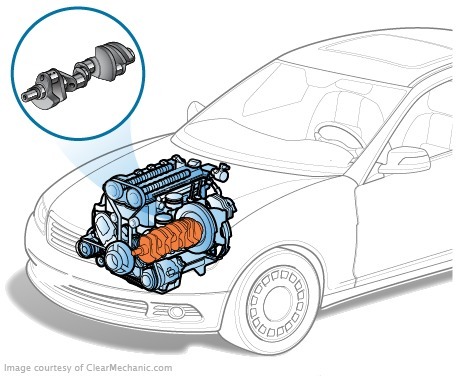

crankshaft device

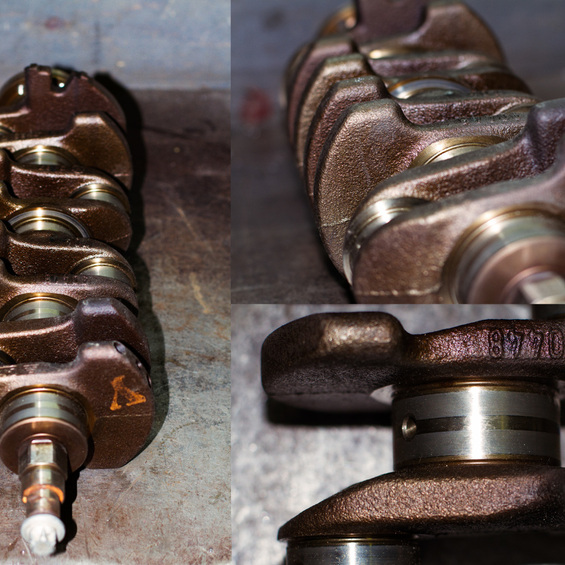

The crankshaft is completely consistent with the name, as it consists of several knees located on the same axis. These are large protruths of a complex shape that are distinguished by a single whole with shaft. The saline is intended for the fixation of the caps, which in turn enshrine pistons. There are other elements in the shaft. First of all, this is the neck, that is, cylindrical "NDRs" between the knees, which allow the shaft to be fixed in the body of the cylinder block.

The crankshaft during the operation of the motor vehicle shall be developed to the engine in which it is fitted. Therefore, it is not recommended to rearrange the used wheel knee

The poorly defined shaft would not be able to rotate for a long time, so the neck is located along its entire length, creating several points of support. The vapors allow it to rotate in the cylinder block. The neck is based on special bearings which do not have roller skaters. These bearings are called native liners. The role of balls or roller skates is a lubricant which is a continuous flow to the space between them and the supporting neck.

Other backbones, which are called steps, are present in the design of the caps. Unlike indigenous peoples, they are not on the same axis as the indigenous neck, but on the side. Root certs with holes in the lower ends of the steps.

Each knee is composed of two cheeks and one neck, on which the lower end of the cap is "above". The tumblers, moving up and down, are squeeoking on the neck and pushing the shaft to spin. As a result, the transformation of the back and forth motion is carried out.

In addition to its knees, the crankshaft has a counterweight to balance the residual mass of the shaft. As important as these elements are, it is possible to imagine that the average speed of rotation of the crankshaft during engine operation is approximately 3000 revolutions per minute. The crankshaft is the details of the complex shape. To prevent heavy knees from creating destructive vibrations, each of them is balanced by its counterweight.

Although conditions of the highest accuracy are performed in the crankshaft production, the minimum rotational speed is inevitable. This is why the current sappers are the same for Zaporozhka and Mercedes

Inside the body of the crankshaft, there are special channels for feeding the oil to the indigenous and the ashtun liners and the special voids, which are closed corks, for the collection of dirt and tear pieces of the oil present in the oil. With this system, the rotational shaft is gently sliding in the anchorage points, which are oily smeed with pure motor oil. During the repair of the crankshaft, the pluds are opened and the empty oil and gas supply channels are cleaned and the air is pressurized.

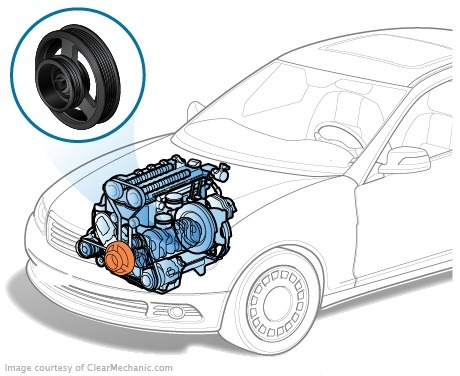

At the front end (sock) of the milling machine, by means of a milling machine, a lumbar rod is removed for the attachment of the sprocket of the GRM and the pulsation of the auxiliary machinery.

At the back end of the loom, the flange is caraved, with a central hole under the bearings, which supports the PPC's primary shaft. The flange also has threaded cutter holes.

Front and rear of the crankshaft seal that prevents the oil from escaping in the places where the end of the flywheel comes out of the cylinder block.

In addition to internal combustion engines, and even before they were introduced, the crankshaft was used in piston engines, compressors, pumps, press installations and other mechanisms where the screwdriver mechanism is used.

The crankshaft-the part for each engine is unique, and it is possible, but not recommended, to move it from one engine to another. On each engine, the shaft of the shaft is located in its own way and the location depends on the location and number of cylinders, the operating cycle, the length of the piston and the other mass of the parameters.

Material and crankshaft manufacture

The alloy steel or high-strength iron cast iron is used for the manufacture of the crankshaft. For the production of forged wheels, carbonaceous or alloyed steel is used, and for cast iron, high strength globular cast iron, or forged cast iron or alloy steel. Stubs for gross receive either a casting or a hot stamping.

The crankshaft is a big detail with the precision of the production of the seamstress

Processing of finished machining in a mechanical way on machines consists of a series of operations: draft, receive, clean, and fine. In this case, the mechanical processing of the shaft shall be increased by the mechanical handling of the shaft.

In connection with the complex configuration of the crankshaft, a number of operations are performed at separate automatic stations, on special machines. This is the execution of centering and subcutting of the torts, drilling of holes, processing of indigenous and shadimian neck, flyover, and dynamic balancing.