Prerequisites for hybrid drives

The resources of planet Earth are not infinite, and for the survival of mankind, there is a need for a large supply of energy-generating raw materials, including oil, the most important of all types. Its holdings are constantly decreasing, leading to higher prices for petroleum products and fuel for cars in particular.

In addition to this internal combustion engine used in transport, a large number of harmful pollutants are released during their work. It is mainly carbon monoxide and nitrogen. All these factors have led to the fact that today any development on the use of alternative engines or hybrids is extraordinarily relevant.

Based on this today, almost every company producing cars has a model with a hybrid force installation in its ruler. The development of environmentally friendly power plants also obliges and continuously toughening the norms of EURO, ECE, SULEV, TLEV and others. This also includes lower fuel consumption, resulting in significant savings in the cost of operating the hybrid transport.

What Is Hybrid Drive?

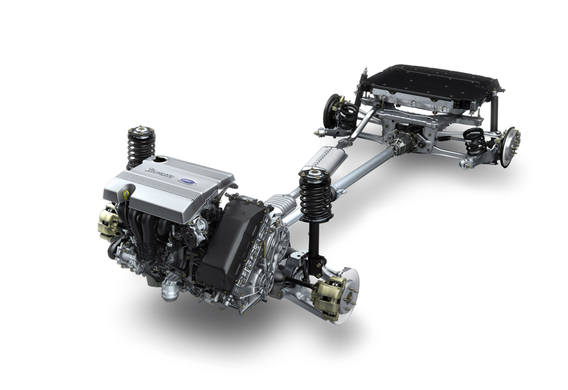

The term "hybrid engine" means the use of two or more different power installations. This is mainly a combination of internal combustion engine and an electric motor to maximize their benefits while compensating for the deficiencies.

For example, the main advantage of the internal combustion engine and its use in most vehicles is the fuel flow. The range is achieved by a high concentration of energy in the fuel used, mainly hydrocarbons. The reverse of the medal is a fairly high level of noise and high emissions of various harmful substances, as well as the ability to operate only in one speed interval, which causes devices such as clutch and transmission to be added.

In addition, the efficiency of the internal combustion engine is relatively low and ranges between 20 and 30 per cent and significantly increases the emissions from the uniform movement.

While the electric motor is substantially higher than the KPI (about 80%), is not subject to harmful emissions, does not produce noise and is able to generate torque from the moment of its launch.

However, the electric engine currently has a number of limitations on its use, namely, a limited number of existing batteries, weight, size, and cost, usable for ground transportation.

Hybrid-drive considerations

The hybrid drive is designed to address the reduction or elimination of deficiencies in the application of one engine/engine type and to take advantage of their advantages in combination.

For example, in one of the first such installations called "serially hybrid" combinations, the engine only serves as a generator drive to charge the electric motor. In this case, the traction force only creates an electric motor.

Such a hybrid drive solution significantly reduces the fuel consumption, as the internal combustion engine spends the average power, thus allowing it to operate in an even optimal mode. In such a "parallel hybrid" configuration and electric motor and the internal combustion engine are connected to the driving wheels through appropriate transmission mechanisms.

In modern hybrid vehicles, more than one electric motor is used, up to the installation of electric motors on each wheel of the car. This is made possible thanks to the latest developments of engineers who have achieved a significant increase in mileage mileage without charging. In addition, most of the vehicles are able to recharge the battery from the usual household network.

In addition to the serial hybrid drive, a parallel drive is used to summarize the power of all engines, significantly increasing the total power of the hybrid vehicle. Increasing the power in turn provides an opportunity to increase the dynamics of the car and make it easier to disperse.

Three different types of electric motors have been developed for the hybrid electric motor, both functionally and in their structure.

Type of electric motors used for hybrid power train: synchronous engine, synchronous engine, DC engine.

The best of these electric motors is now the 3-phase synchronous engine on permanent magnets.

Hybrid-drive management

The developed hybrid drive systems need special management schemes to ensure optimal and failsafe operation of all its elements. This task is assigned to microprocessor circuits with separate action algorithms.

There are many sensors that transmit their information to the central control. Since such a drive has to solve several tasks simultaneously and to take a lot of instant decisions, this task is only subject to the onboard computer. For example, the computer accepts simultaneous signals from the actuator's sensors: information about the state of the internal combustion engine and the electric motor; the engine off or the acceleration of the motion; the temperature at the different points of the transmission; the state of charge of the batteries or instantaneous capacitors.

The control computer in the hybrid drive system controls the main circuit of the electric motor and, above all, the frequency converter (or frequency-controlled electric drive). In other words, the speed and speed of the electric motor shall be controlled by changing the frequency and voltage of the electric motor. With this managed conversion, the KPI is 98%, thanks to the consumption of an active part of the load current.