The gas turbine engine is successfully used in tanks and aviation. Unfortunately, a number of structural limitations do not allow this progressive design to be used as a power plant for a passenger car.

The advantage of engines of this type is that they have the highest specific power in the existing power installations of internal combustion engines up to 6 kW/kg. In addition, the gas turbine engine can operate on a variety of liquid fuels, not just petrol or diesel.

History of gas turbine creation

The first gas turbine was developed in 1519. It differed significantly from modern devices and was applied in the "minor mechanization sphere". The turbine turned the vertel intended for the hot meat. The gas turbine was used and the inventor of John Barbera was brought in.

One of the first gas turbine engines for tanks was developed by BMW in 1944. It was tested on a self-propelled Panther installation

In 1950, Rover was developed a gas turbine engine for cars. As a result, the pilot model of the racing car "JET1" was introduced. The engine's engine was positioned behind the seats, the air intakes were mounted on the sides, and the exhaust gas outlets were located on the upper back. The speed of rotation of the turbine reached 50,000 revolutions per minute. The fuel used was petrol, paraffin oil and diesel fuel. The maximum speed with which the vehicle was able to move was 140 km/h. Due to the high consumption of fuel, cars with a gas turbine engine did not enjoy special demand.

The only case of using a gas turbine in the design of a motorcycle-MTT Y2K Turbine Superbike with DCA Rolls-Royce-Allison Model 250

Modernizing the device and constructing the model "BRM", digging "Rover" took part in the racing events of 1963 and set a record: the car was racing to a speed of 229 mph. Later, other car manufacturers took part in similar competitions. For example, "Howmet" produced a "TX" model that worked at the gas turbine engine and became a racing favorite several times.

The only model of a serial car with a gas turbine designed for public transport was released by the American concern Chrysler in 1963. Fifty copies of the car, the Chrysler Turbine, were manually collected by the specialists of the Italian bodywork Ghia. The vehicles were not sold, but were distributed to volunteers for two years for testing. The experiment was successful, but the new production required the construction of a new engine plant, and Chrysler did not venture to invest a lot of money. In the seventies, when environmental standards were substantially tightened in the US, and in addition to the fuel crisis, the company withdrew its oil price.

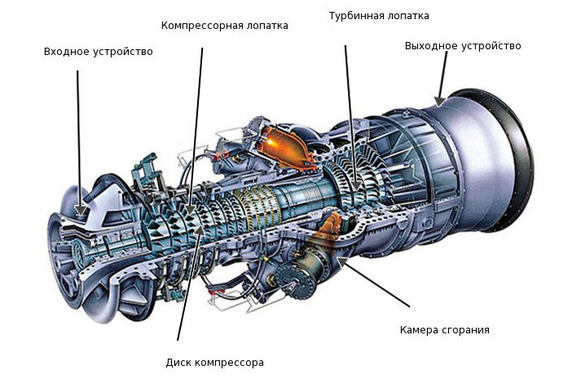

Device and operation principle of gas turbine

The air shall be compressed and heated to the compressor. It then enters the combustion chamber, which also includes some fuel. Due to the high speed, the air and fuel are ignet in the crash. During combustion, the energy shall be energy converted to mechanical work by rotation. A part of this energy is used for air compression in a compressor. The other part goes into the electric generator. Then the exhaust gas is sent to the tool.

Advantage and disadvantages of gas turbine engines

Gas turbine engines are much larger than piston motors. Due to the ability to develop large turnover, the device has a high capacity, but it has compact dimensions. The fuel uses kerosene or diesel fuel. The mass of the gas turbine engine is 10 times less than the mass of the equivalent engine of the internal combustion engine. Due to lack of fittings, the gas turbine does not require an extensive cooling system.

Chrysler engineers who created the only small [ [ gas turbine]] car with a gas turbine have learned that the best fuel for the TBG is a conventional kerosene

The main drawback is the increased fuel consumption caused by the need to artificially limit the temperature of the gases. The restriction is that in the case of a motor vehicle the engine shall be mounted inside the body, not under the wing, as in the case of the aircraft, for example. Accordingly, the engine temperature shall not exceed 700 degrees. Metals that are resistant to such temperatures have a very high cost. This problem is often of interest to scientists, and gas turbine engines with good economic performance should be introduced in the near future. It is obvious that this will happen only if the problem of the withdrawal of large amounts of heat is solved, which will allow to put "undual" engines on the cars, in whose design the problem of economy has been solved. The deficiencies also include high ambient air quality requirements and lack of engine braking.

Two-braked gas turbine equipped with a heat exchanger

This type of engine meets the most frequently. Compared to analogues, these devices meet the higher requirements for car dynamics. The two boilers include the special (for the compressor drive) and the traction (wheel drive) of the turbines that are not connected. These engines help to improve the dynamical properties of the car and allow for a reduction in the number of steps in the gearbox.

After abandoning the mass production of cars with gas turbine engines, Chrysler has destroyed most of the test cases so that the turbines do not hit the car

Unlike reciprocating piston motors, two-wheel gas turbine units assume an automatic increase in the torque when the load increases. This allows the gearshift to be significantly later or not required at all. With equal power, cars with a two-complimvated gas turbine drive are dispersed faster than piston engines. The disadvantages of this species are the complexity of the manufacture, the increase in size and weight due to the presence of additional components: heat exchanger, gas and air ducts.

Gas turbine free-piston engine

At present, the gas turbine engines of this design are the most promising for the construction of cars. The device is a block that combines reciprocating compressor and two-stroke diesel. The middle part contains a cylinder with a straighter flushing, which has two related special piston engines in place. In the case of pistons, the air will be burned and the fuel is ignite. Burned fuel contributes to the formation of gases which, at a high temperature and pressure, provoke a difference of piston to the side. The exhaust gas is then passed through the exhaust gas windows to the gas collector. Thanks to the presence of the purging windows, compressed air penetrates into the cylinder, which facilitates the purification of the exhaust gases and prepares the engine for the next cycle. The process is then repeated.