One of the main trends of the modern automotive industry is to eliminate the human factor where the electronics are successful. In certain situations, the driver accepts the error of not squeeing the gear until the end of the clutch or not in time. The errors have a devastating effect on the engine and the transmission. Electronic systems are capable of controlling more accurately the various devices. One of the first successful devices of this kind has been the electronic throttle. Assignment of electronic throttle

Assignment of electronic throttle

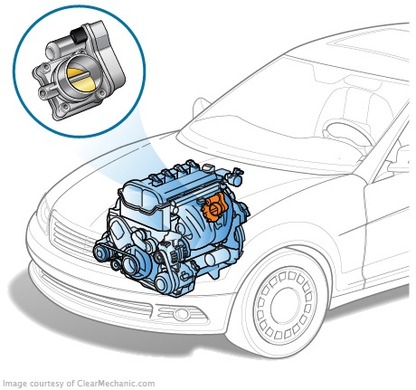

Electronic throttle, like the traditional mechanical flap, controls the flow of air into the internal combustion chamber of the motor vehicle. The driver changes the position of the shale installed in the body form of the pipe through which the air flow of the variable power passes.

The use of electronic throttle control makes it possible to achieve greater efficiency from the engine as they rule out a human error in the accelerator control

The mechanism for the conversion to electronic control of the site remained the same. Only the transmission system has changed fundamentally. The axis of the traditional shale is connected to the pedal of the gas by the cable. The driver reduces the cable, which rotates the salon axis, opening it. In the electronic throttle, the axis is driven by an electric motor, and there is no direct link between the gas pedal and the shale. In this case, the pedal performs the function of the remote control. The electronics allow you to change the position of the box quickly and precisely as much as necessary to enable the engine to operate at a given load. Accordingly, the design avoids capacity loss, reduces fuel costs, and serves as a cold start device.

History of creation

The system for mixing the petrol vapor with the air, including the mechanical throttle, was invented in 1872 by the engineers of Daimler Daimler and William Maybach. In this way, the system lasted for more than a century until German company Bosch developed an electronic version of the throttle.

The electronic throttle control mechanism needs to be cleaned periodically, as it gets a small dust that is not able to weed out a very good filter

For the first time, the electronic throttle was applied to a racing car. In 1985, Volkswagen experimented on the second generation of Golf, trying to make a car out of it for racing. For this, Golf was equipped with two engines at once, and the E-Gas system was used for the synchronization of their capacities. The throttle in one of them was mechanically controlled, and the other was used by an electric drive that resynchronized the position of the shale. As a result, the total engine power of 500 horsepower engine was reached and the acceleration was 3.4 seconds. A good result for 1985!

For civilian cars, the electronic throttle became available almost at the same time. Manufacturers such as Saab, Mercedes-Benz and BMW are equipped with electric motor vehicles. However, it has not been possible to completely replace the simple and cheap machinery in production.

Electronic throttle control

An electronic throttle node consists of the following elements:

Electronic control unit;

electric motor, control transmission of the throttle;

A mechanism consisting of the hull, the axis and the shale;

Gas pedal position sensor;

A throttle position sensor.

The position sensor is mounted on the shell. It shall change when the position of the gear is changed on the axis of the axle. The data is fixed and the signal, whose voltage varies according to the position, is transmitted to the control unit. During processing, the signal voltage is interpreted as a percentage: from 0 to 100%. 0%-the lock is closed, 100% is open completely.

Like many other innovations, electronic throttle control has first found application in the world of sports. With the help of electric power, the problem of managing multiple throttle was solved

The gas pedal sensor shall record the change in its position and transmit the data to the control unit. The data is processed and, depending on the pedal position, the cover is started, opening or covering it. There is also feedback. The throttle position is monitored by the sensor and the control unit, receiving the signal, compares the angle of the open box with the gas pedal position. As a result, the electronic control supports engine idling by controlling the optimal position of the engine according to the specified parameters.

Evolution of the electronic throttle

In modern cars, in addition to engine speed control, the electronic throttle performs several additional functions.

The cold start system, which was also encountered on the carburetors, was integrated into the hural. An additional sensor is used to measure the coolant temperature and transmits the data to the control unit. For a faster and more efficient engine warm-up, the system opens the hole, providing high speed, usually in the 1500 rpm area. As the temperature rises, the lock is gradually closed, and the revolutions are reduced to idle.

Also, electronics help offset the load on the engine when additional systems are connected. The climate system, generator, cruise control and other systems increase the load on the knee. The control unit handles the load data and then calculates the optimum position of the shale in a particular mode of operation.

The electronic throttle knots have a system of rapid warming of the engine, making it easier to launch a car in the winter

In general, the use of the electronic throttle significantly improves the efficiency of the car, but the installation of the system has a high cost, which in general does not allow it to be used for budget models of automobiles.

Characteristics of the electronic throttle

Like any other complex device, the electronic dusk node complicates the design of the car and is potentially a source of problems. The electronics are exposed to adverse climatic conditions and may not function correctly at extremely low temperature or humidity. In the post-warranty period, the replacement of the electronic throttle may be the source of expenses for the owner of the car, as the site is usually not monotonian and completely changed.

The electronic throttle control mechanism is no different from the traditional one, so the shale needs to be cleaned periodically, especially when operating under severe conditions.