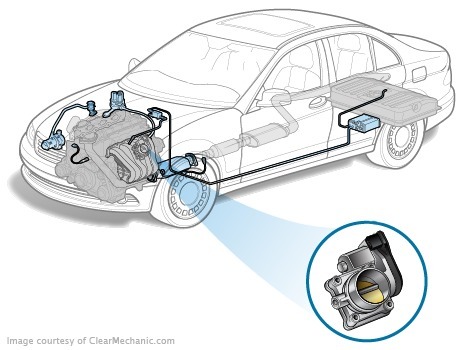

Everyone knows that the car needs fuel. When the engine speeds up, it gets more air and gasoline. A throttle control is responsible for the preparation of this "combustible cocktail" in the correct proportions. Role of the throttle in the intake system

Role of the throttle in the intake system

The internal combustion engine has a intake system that combines the supply of fuel and air into the combustion chamber. The fuel system is responsible for the movement of the fuel, its injection into the internal combustion chamber and the ignition. The throttle relates to the air part of the intake system.

The throttle is a "by-product" of finding cheap fuel for engines that were preoccupied by the inventors of the 19th century

The system shall be diluted and modified according to the engine speed. In opening, the throttle not only regulates the flow of air, but also the total quantity of the mixture falling into the cylinders: when opening into the reservoir is greater air, and the nozzles on the control unit command a high dose of fuel.

History of the throttle

If you look at the history of the automotive industry, you can find several significant facts. Not immediately as fuel for engines started to use petrol. Initially, the gas was used for this purpose. This gave the possibility of avoiding the use of a separate fuel mixing device because the gas already contained oxygen molecules in their composition, thus could burn without mixing with air. However, the light gas was a very expensive and scarce product. In the late nineteenth century, for example, there were only two factories in Russia.

In this regard, scientists have been searching for cheaper fuel. The best option was to use gasoline, kerosene and diesel fuel for this purpose.

With the transition to liquid fuels in 1872, the first carburetor was invented. A few later he was patented by Daimler and William Maybach. One of the most important elements of the system was the throttle, which solved the problem of the mix of fuel and air.

throttle design

In fact, the throttle valve is a valve that, when opened, increases the pressure in the system to the atmospheric pressure, and when closing reduces the volume of air to the vacuum state. The shale structure is very simple: the pipe is fitted with an axle to which a round plank is attached to the centre. The transmission shall turn the axle and, with the axis, turn and the shank. Correspondingly, the pipe of the pipe grows, then decreases. This process is called throttling.

Contrary to popular belief, diesel engines do not. Their design has a regulated fuel feed principle

In the original design, which was designed for the carburetor, the transmission was mechanical-the axis was driven by a cable attached to the accelerator pedal. With the advent of the injectors, this construction has remained unchanged for a long time, until engineers have developed an electric motor drive. The pedal has become an electronic control device that supplies a different level signal to the throttle unit.

The mechanical drive throttle control is most often used on budget vehicles. Practically all cars of the model series of VAZ were installed with mechanical actuation.

The simplicity and cost of production-these qualities of mechanical throttle allow it to be applied for a century and a half

Unlike the mechanical throttle, a modern electronic knot already does not obey the driver's will in its entirety. Adjust the quantity of petrol and air that fall into the engine, the driver is assisted by a number of sensors:

A throttle position sensor;

Gas pedal position sensor;

The switch is on the clutch pedal and the gas, and so on.

The sensors and the electronic control unit, combined with the electric control transmission, allow for the most flexible control of fuel consumption in different driving modes and stabilize the idle speed of the engine.

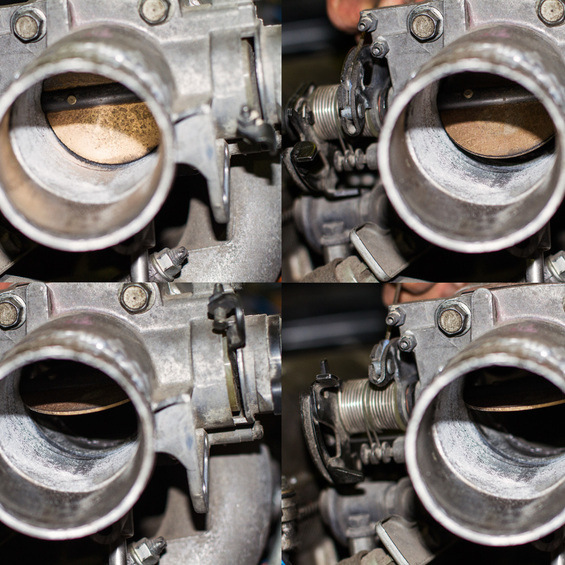

Why does the throttle need for periodic cleaning?

The main problem with the operation of the throttle is that the air is through it. The conditions on the road are different, and in some cases the smallest dust particles penetrates even through a quality air filter. There is also another source of contamination-oil dust that penetrates through the crankcase ventilation system. The two of these substations, mingling together, form a pretty solid bloom on the flap. Gradually, they are infected with the edge of the plate, and the filler shall be closed to the end.

The throttle of the throttle is one of the most common causes of car entry

Model signs of throttle contamination:

-difficulties in starting the engine

-unstable idle

-chiroting at speeds below 20 km/h

As a general rule, it is sufficient to detach the air filter from the canister and to spray the aerosol plate several times in order to clean the carburettors or injectors. The tool will dissolve it, and then it can be removed with a cloth or paper towel.

To solve more serious problems, you must remove the throttle control, release it from the rubber sealants and process the same aerosol. If the metal is mechanical and has no built-in electronics, it is expeditive to put it on the night in the petrol tank. Any car service can perform this cleaning procedure quickly and relatively cheap. The cost of work may vary depending on the complexity and degree of contamination of the system.