Description of centrifugal actuator

This type of compressor belongs to the scapula. The principle of their work is based on the mechanism of interaction between the airflow with the wheels of the wheel and fixed elements of the machine.

With a number of advantages, centrifugal chants are not as popular as turbochargers. This is due to the increased noise level of the machine and the presence of a special drive, which partially selects the engine power.

Device and operating principle of centrifugal compressor

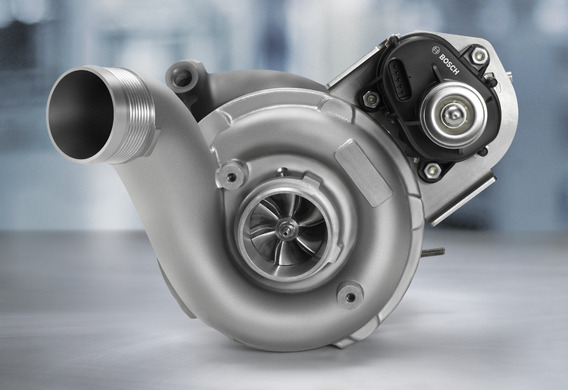

The design of the centrifugal compressor includes:-shell;-input device;-a retina, or a work wheel;-diffuser;-a snail air inlet.

The centrifugal compressor has two parts: blade and chuck.

Through the filter, the air shall be supplied to the input device of the injection device which is in the narrowing form. This ensures that the device is evenly distributed to the device on the sleek or smooth shaft. The working wheel unfolds the airflow into radial direction and, thanks to centrifugal force, full pressure increases.

The wheel shaft of the centrifugal compressor is associated with the motor gear with the engine crankshaft.

The compressor's cover is equipped with a center to the edge of the scapula. There are two types of work wheels: radial, shoulder-shoulder, and reactive with curved. The last species of the species have a higher degree of air compression, which means higher efficiency. Unfortunately, the complexity of their manufacture makes jet wheels much more expensive.

The main characteristics of the centrifugal injection work are the pressure increase, the air flow and the efficiency. The range of these parameters is wide enough and depends on the design of the compressor.

The pressure rise of 1.2 A. For forced combined engines, the pressure rise is up to 3.3.5 A.

In order to reduce the power selected by the engine of the centrifugal compressor, additional couplers are installed. They are controlled by electronics and cut off the crankshaft from the injection engine in certain modes of operation of the propulsion system. It saves fuel.

The disadvantages of centrifugal compressors include their relatively low efficiency and low efficiency at low engine speeds.