Towards the end of the 18th century, mankind realized the need to find a replacement for complex and demanding vapour machines. The main part of the industrial sector at that time was small enterprises and workshops. The most common engines at the time are bulky steam engines. They didn' t like everyone. Engineers understood that other power plants-launching, small size and capacity-were needed to improve production efficiency.

History of gasoline engine invention

The advent of internal combustion engines was the opening of a new light gas, made at the turn of the eighteenth and nineteenth centuries by French engineer F. Lebón.

The patent for the way he was received and used was in 1799. The light gas has become a real breakthrough in lighting technology.

And after 2 years, Lebón received the following patent-on the construction of the gas engine. It consisted of mixing compartments and two compressors. One of them was pumping compressed air into the cell, the other-a compressed, fresh-made gas from the gas generator. This mixture came into the working cylinder and ignet. The working cameras were on both sides of the piston and alternated.

The gas engine was the first step towards the creation of an internal combustion engine. But unfortunately, the development in this direction has been suspended with the tragic death of Lebon. Further attempts by many inventors did not result in a gas power installation that could compete with steam.

The first internal combustion engine in the world is considered to be an aggregate, patented by Jean Etienne Lenoir in 1859.

The Belgian engineer decided to inflame the gas mixture with an electric spark. The Lenoir engine was a double act. The air and gas were alternated with a lower gold-plated cylinder located on either side of the piston. The top gold was the answer for the exhaust gas. Air and gas were supplied to the goldman through separate channels, while the intake of the mixture to the cavity was only up to half of the stroke. Then the intake window closed, and the electric spark ignits the resulting mixture, causing it to expand and to push the piston. When the reaction was over, the second goldman produced the exhaust gas. At that time, the cylinder on the other side of the piston was ignites of a fuel-air mixture.

To avoid the charge of the piston due to thermal expansion, Lenoir supplemented its construction with a cooling water system and a lubricant system. Despite low efficiency (about 4 per cent), misfiring, large gas and grease gas flow rates, Lenoir motors have been widely distributed and have had commercial success.

In 1864, there was a better gas power plant designed by Augustus Otto. Although he has given up the electric ignition, the design proposed by them led to a more complete expansion of combustion products, which means that the engine will be increased to 15 per cent. This exceeded all the devices that existed at that time! In addition, the new engine was more economical than Lenoir's engine five times.

By improving his invention, Otto applied to the construction of the cryopohic gear that replaced the serrated rack. Soon, along with the Langen industrialist, he started production of four-stroke gas engines. This cycle is the backbone of the work of the DMF until today.

The use of light gas as a fuel for internal combustion engines severely limited their scope, so active searches for affordable alternatives have not ceased. In 1872, American Brighton was offered a "vaporizing" carburetor where kerosene was used as fuel. But his design was too imperfect.

A truly serviceable petrol engine appears only after 10 years. He developed a Daimler, a former member of Otto's board of directors. He presented a gasoline-based propulsion system that was applicable to transport, but the idea was rejected by his boss. Therefore, in 1882, Daimler and Maybach leave Otto and Company and create their own workshop. Their goal was ambitious: to create a light, compact and powerful engine capable of moving the crew.

The first child of Daimler and Maybach was fixed. The evaporation of petrol and the ignition system were far from perfect.

A simple and reliable system has been offered by the D constructor. Banks in 1893. The carburetor he was invented has become a modern one. After that, the progress in the development of the DSC began to gain momentum. The number of cylinders was increased and the number of cylinders increased. 4-cylinder power plants are widely distributed, ensuring that the crankshaft rotational is evenly distributed.

For the first time, the petrol engine was used in Carla Bentz's wheel. The German AutoDesigner built it in 1885. The three-wheeled machine was speeding up to 16 miles an hour. And after 13 years, Carl Benz created a four-wheeler, the 3-horsepower engine, which could be "running" at 30 km/h!

The first one-in our usual sense-the petrol engine car saw the light in 1895. It was created by French engineers R. Panar and E Levassan. The car was equipped with a sedan and equipped with the power installation of Daimler, which lay ahead and covered the hood of the hood. The moment of torque was transmitted to the rear wheels with the help of a crane shaft. The car had walls of the body, windshield, roof, rubber tyres, gearbox and gear lever. This was the beginning of the era of petrol-fuelled vehicles. Among the pioneers of the construction of such self-propelled crews were Z. Marcus, A. Peugeot, Reno Brothers, F. U. Lenchester, G. Austin and H. Ford.

Petrol engine design and operation principle

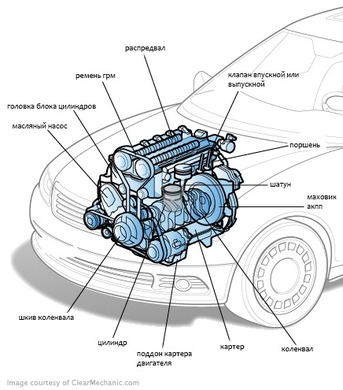

The device and principle of the operation of modern petrol engines is best considered by the example of a single-cylinder four-stroke installation because they differ only by the number of cylinders. Single-cylinder gas engine consists of:-silencer;-springs of valve;-carburettor;-ventilation;-spark plugs;-valve;-flywheel;-flywheel;-wheel shaft.

The compression act occurs at the next half of the crankshaft revolution. The port is moved from the NRMM to the TDC. Both valves remain closed at this time. The working mixture is compressed, and the pressure and temperature increase in the cylinder.

The essence of the extension is a working move. After the end of the compression of the working mixture, it ignites from the spark generated by the candle. Combustion process leads to an increase in temperature and pressure (UAH 2,500 and 5 MPa). The piston begins to move downstream and acts on the Jackass, which pushes the crankshaft into a rotational movement. The useful work of the expansion tact is the conversion of thermal energy into mechanical energy. When the piston is approaching NRMM, the exhaust valve opening is taking place. The temperature and pressure in the cylinder is dropping (1.200 g. C, 0.65 MPa).

The release of the issue begins with the movement of piston in the RMT. In doing so, exhaust gases shall be pushed into the fully open valve. At the end of the cycle, the temperature and pressure in the cylinder shall be dropped (500 g. C, 0.1 MPa). But a certain percentage of the waste gas remains in the cylinder and participates in the education of the working mixture of the next cycle.

The four cycles of engine operation shall be cycle. The wheel attached to the crankshaft is conducive to the smooth and steady operation of the plant.

Benefits and deficiencies of gasoline engines

The advantages of petrol DSC are significant capacity per unit of volume, large resource, exhaust of the exhaust system.

In addition, it is important to note the low level of noise of the propulsion system and the lack of necessity for the starter. The gasoline DMF is achieving great speed and is therefore successfully used in small cars and drive aggressive driving behaviour.

The deficiencies of the petrol engines are low CPD (up to 30%), high quality of the fuel mix and low efficiency at low speed. There has been a lot of criticism recently in the address of the environmental indicators of gasoline DMWs. High carbon monoxide content is harmful to the environment.

In addition, such engines strengthen the world's car fleet's dependence on, alas, unlimitless natural resources. And, while the gasoline DMF has not exhausted its potential, alternative fuels and sources of energy are being actively sought and developed around the world.