The intake manifold is the most important part of the internal combustion engine intake system. In the intake manifold, the air stream is mixed with petrol, forming a fuel-air mixture, and distributed in cylinders. Why do you need a intake manifold?

Why do you need a intake manifold?

The primary function of intake manifold in the uniform distribution of the fuel-air mixture (or simply air in direct injection engines) on cylinders. The balance distribution is necessary to optimize the performance of the engine. The intake manifold also serves as the anchorage for the carburettor or the injection equipment, the throttle control and the other components of the engine.

The appearance of the intake manifold with variable geometry has allowed the system to turn off of a part of the cylinders on the V8 and V10 engines

A partial depression (below atmospheric pressure) is formed due to the top-down movement of piston in the intake manifold. Engine developers have learned to use a vacuum as a source of drive power for secondary systems: vacuum amplifier of the brakes, control devices for harmful emissions, cruise control devices, control-ignition devices, windshield wipers, crankcase ventilation systems, and so on, depending on the brand of the car.

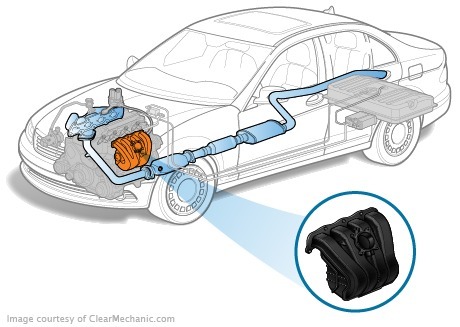

Inlet manifold construction and materials

The induction manifold is a closed tank of a complex shape with a common camera (the resiver) and the transfer tube (by number of engine cylinders). For a long time, the engines have been installed by collectors from aluminium or cast iron, but composite materials have become increasingly popular since the early 2000s. The plastic manifolds have been made of the engines of Ford Zetec 2.0, Duratec 2.0 and 2.3 and many other modern aggregates.

Combustible mixture principle and characteristic

The carburetor or propellant propellant spray the fuel in the collector chamber. At the expense of electrostatic forces, a drop of fuel is immediately posted on the chamber and is seeking to settle on the walls of the collector or to gather in larger drops in the air. Both actions are undesirable because they lead to mixtures of uneven densities. The more the fuel is sprayed, the more intense and more light it burns in the cylinders. In order to achieve the necessary turbulence and pressure in the manifold, and thus the correct dispersal of the fuel, the internal surfaces of the inlet pipes of the manifold and the head of the cylinder shall be left unrustled. The surface shall not be too crude, as there may be an unnecessary turbulence that will lead to higher pressure and lower engine power.

The full-grown intake manifold, designed for racing cars, has become a standard attribute for the engine of a modern passenger car

The intake manifold must have a fixed length, capacity, and form. All these parameters are calculated in the development of the powertrain. The intake manifold ends with air channels that route the air to the engine's intake valves. In diesel and direct injection systems, the airflow shall be sprawdable and directed to a cylinder in which mixing with fuel occurs.

Receb manifold length and shape value

In recent times, the length and shape of the intake manifold or intake manifold channels is of great importance. The canal is not designed to have sharp curvings and sharp corners, because in these places, the fuel, mixed with air, will inevitably settle on the walls. In modern collectors, the principle that is born in the bowels of the training of sports cars is used-all individual channels of all cylinders, regardless of distance from the centre, are of equal length.

Such a construction contributes to the fight against the so-called "resonance of Helmholtz". The fuel-air mixture at the time of opening of the intake valve shall be driven over the manifold to the cylinder at a high speed. When the valve is closed, the air that failed to pass into the combustion chamber continues to pressurize the closed valve by creating a high pressure area. Under its effect, the air tends to return to the upper part of the reservoir. Thus, the channel will produce a backflow that stops when the valve is opened the next time. The process of changing the direction of flow in traditional collectors is constantly occurring at a speed close to the supersonic. The fact is that in addition to opening and closing the valves, the air is aimed at a constant change of direction in accordance with the resonance phenomenon, which was opened by Hermann von Helmholz, author of classical work on acoustics. Of course, when the air is constantly "hanging around" is the inevitable loss of power. For the first time, the collectors optimized for the resonance of the Helmholtz were used in the Chrysler V10 engines, which were equipped with the Dodge Viper vehicles and Dodge Ram pickups. Other manufacturers have subsequently adopted the design.

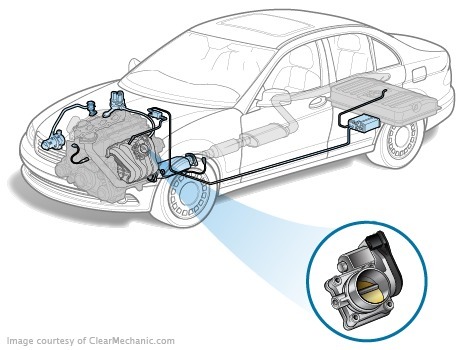

Inlet manifold with variable geometry

Another innovation that has been gaining more and more supporters lately has been the design of the intake manifold with variable geometry. At this point, there are several general principles for the implementation of this design. One of these implies two ways in which airflow or air-to-air can flow through the individual channel leading to the cylinder, short and long. In a certain mode, the valve installed in the channel closes the short path.

When the intake manifold is removed, the replacement of the pad shall be mandatory, as the operation of the entire intake system may depend on the leakproofness of the connection

The second design means the fitting of the valve into the chamber. When certain conditions are met, the lockdown reduces the internal volume of the chamber. For engines with a large number of cylinders (bigger than 4), there are even more complex systems. By the way, it is precisely because of this principle that the part of the cylinders in the V8 engines-part of the chamber to which the channels of one half of the cylinders are connected is blocked, and the fuel-air mixture is not covered.

Intake manifold maintenance issues

The quality and condition of the gaskets is of utmost importance for the intake manifold. Therefore, if the collector has to be removed for some reason, it is necessary to ensure that all seals are in good condition and if the gaskets are torn, they must be changed to leak.

It is important to know that the aluminium and plastic sewers, which are installed on the vast majority of modern engines, are more deformed than the cast-iron ones that occur only on older engines (e.g. "classic" VAZ vehicles). A dynamometer shall be used to avoid cracks and biases in order to protract the manifolate. As a rule, it is recommended to start from the center and gradually move to the periphery, alternately prolonging the nut on one side and on the other side.