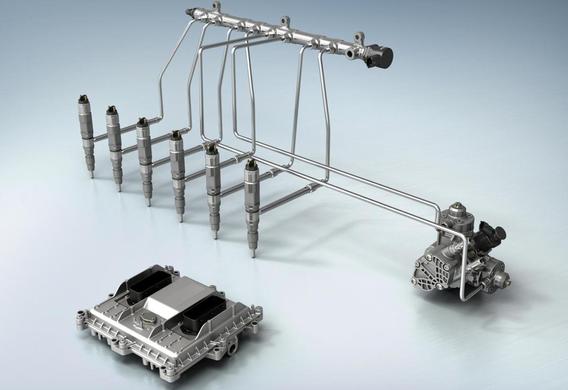

The fuel rail or gear is a floor of the floor of the tube with two sides closed off and the pipes of the smaller diameter through which the fuel is applied to the nozzle.

The fuel ramp is one of the elements "delivered" to the gasoline engine from diesel engine. Another known element, "moving" from there to direct injection systems, TNT

In some cases, the injections are attached directly to the ramp. The fuel ramp is used in almost all of the distributed injection systems, although in some constructions the dissipator is derived from the shell.

History of fuel rail

In the design of the injection system, fuel ramp came from the practice of diesel engines, which had been equipped with a distributed injection since invention. In the era of the carburetor injection, the fuel ramp on petrol engines was not used because the fuel is centralized and not under pressure.

Design and location of fuel rail

The ramp is generally installed on the intake manifold. In addition to the supply duct, the ramp is fitted with an opening with a shut-off device to attach a pressure gauge that controls the pressure of the fuel. To prevent contamination, it is closed with carvings. Most often, the ramp is made of a steel seamless pipe capable of withstanding high pressures. In the case of a diesel engine equipped with common rail, this pressure can be very high.

Fuel rail's main purpose is the supply of fuel and distribution to the nozzle.

Caution is needed to remove the fuel injects from the ramp. One wrong movement may cause the nozzle to be replaced

When the charging pump is operating, the fuel shall be supplied to the supply line located in the head of the unit. In the ramp, the fuel is moving towards the far cylinder itself. Some of the design of the injection systems provide for heating of the heat, which is the engine of the engine. Warming improves spraying.

Fuel rail maintenance issues

If for some reason the fuel ramp needs to be removed, it is necessary to proceed with extreme caution because the risk of damaging nozzles and connector pins is high. In no case should dirt be allowed to enter the open pipes and pipes, since it will fall into the nozzle after assembly, and the case will end at least by washing them. You must close the filler panels during the service period. The fuel rail may be cleaned with a container to clean the injectors before being removed. In no circumstances should the ramp be placed in the solvent for washing without disconnecting the nozzle. The fact is that all the holes in the fuel rail are equipped with rubber sealing rings that will be inoperable if they are placed in an aggressive environment. By the way, in any repair guide, you can find a recommendation to change the rubber gaskets in any case, even if they are not externally damaged.