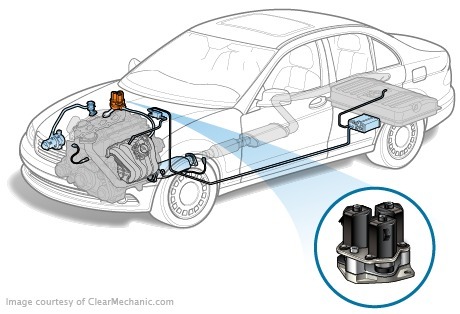

The recycling of crankcase gases (crankcase ventilation) is one of the first simplest devices to reduce the level of harmful substances in the vehicle engine exhaust. The valve shall be overtaken by the exhaust gases in the engine crankcase in the intake manifold where the small oils and harmful substances contained in them are burned. History of the creation of a valve for recycling crankcase gases

History of the creation of a valve for recycling crankcase gases

Exhaust ventilation valves began to appear on motor vehicles in the late 70s of the 20th century. During this time, the world community was first seriously thinking about the harmful effects of exhaust gases on the environment, and the installation of the recycling valve was one of the first steps to improve the exhaust gas composition.

The crankcase recycling valve allows burning of engine oil and harmful substances in the combustion chamber which otherwise would have entered the atmosphere

For about one and a half years, the valve design has undergone successive changes to improve its operation. In 1977 a mechanical valve with positive backpressure was developed and applied. Two years later, in 1979, he replaced a mechanical valve with a negative backpressure. In 1988, the discontinuous 3 solenoid recycling valve began to be used. In 1990, a discontinuous 2 solenoid recycling valve was installed on certain vehicles. This valve controls the recycling flow through one large and one small hole, providing three combinations of flow. The valve has been most reliable and is still in use.

Device and operating principle

In the process of combustion of fuel at very high temperature, nitrogen (which forms a large part of the atmosphere) together with oxygen produces hazardous pollutants-nitrogen oxides (NOx). Under certain conditions in the cylinder of a running engine, the temperature of the combustion engine exceeds the standard level, resulting in a sharp increase in NOx emissions. Some of the gases are cut to the bottom of the cylinder block. To keep the pressure in the crankcase does not increase to the critical point, it must be passionated. Prior to the advent of the recycling system, gases were discharged directly into the atmosphere through the sapon crankcase. A exhaust gas recirculation system has been established to avoid air pollution, which is also saturated with oil dust. The valve installed in the cylinder block shall ensure that the exhaust gas is transferred from the crankcase to the intake manifold.

The crankcase gas recirculation valve does not require the introduction of the actuation mechanism, as the gas is sent to the intake manifold due to the vacuum

The valve operation is based on the discharge that occurs in the intake manifold. With this discharge, the vacuum transformer moves the valve valve opening it.

For modern motor vehicles, two types of crankcase recycling valves are used: mechanical and electronic. The electronic valves, in turn, are discrete and linear.

The body of the vacuum diaphragm in the cylinder block is equipped with a vacuum tube which is attached to the carburetor or body of the head-node. Depending on the level of discharge in the intake manifold, the diaphragm in the throttle opening shall be preset to the lever of the electronic continuously generating switch that generates a signal for transmission to the transmission of the electronic recycling valve. If there is no transmission, the vacuum of the different force, which is changing at the opening and closing of the throttle, shall be transmitted to the valve membrane in the cylinder block without being converted to an electrical signal. When the signal is raised, the diaphragm begins to move upwards, overcoming the calibrated springs, and moves the plunger. The opening is opening in the valve, allowing exhaust gas to flow into the intake manifold.

In the exhaust of an engine equipped with a recycling valve, the NOx and NO2 oxides are lower than in the engine exhaust without a recycling system

During engine operation at idling speed, or when the intake manifold is very small (the throttle is wide open), the discharge is not sufficient to control the diaphragm, and the plunger remains unwielable, and the gas does not enter the intake manifold. Consequently, the recycling process occurs only when the engine is running under load or on high speed.

Crankcase gas recirculation (s)

Thanks to the recycle valve, part of the burned exhaust gas is returned to the intake manifold and is mixed with the new charge air. Since oxygen is the cause of the rise in combustion temperature, the oxygen concentration of the mixture (reintroduction of the exhaust gas) causes the combustion temperature to decrease. As a result, NOx is reduced.

The throttle valve for recycling crankcase gases is responding more slowly to the opening and closing of the throttle

The exhaust gas recirculation process has a number of other benefits. The lower temperatures in the combustion chamber prevent the occurrence of detonation, which gives the opportunity to adjust the timing of the ignition at a wider range, increasing the torque speed. In diesel engines, the recycling process reduces the "hard" operation of the powertrain at idle because the lower oxygen concentration of the fuel-air mixture takes place under different conditions.

Operation of the crankcase ventilation valve

The most common problem causing the valve to be blocked is the accumulation of carbon sediments on the valve or valve plate. In most cases this is due to the engine operation with an incorrect fuel/air ratio of the air-to-air mixture.

If the recycling valve of the crankcase gases is clogged, it will be wedge and slow response to the throttle position when opening and closing.

If the recycling valve is replaced, the pipes attached to the valve should be thoroughly cleaned. In the event that the valve is full, it is unminable in the supply tube. For this reason, the purity of pipelines should be given increased attention.

Interesting facts about the crankcase ventilation system

Perhaps the most common violation of vehicle exploitation regulations in our country is the most common violation of the system for recycling crankcase gases. The fact is that the car enthusiasts do not like this system for the fact that, if the engine is more worn out, it begins to "drive the oil" into the intake manifold. There is always a temptation to "ride a bit more" when it becomes clear that the piston group is in bad shape. For this reason, uncut the output of crankcase gases from the manifold and release gases into the atmosphere, in the recent past have offered to their clients all informal auto attendants.