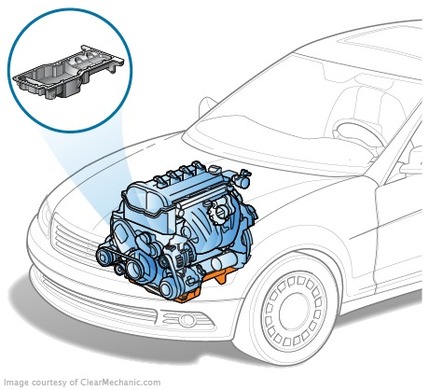

Carter is the lower part of the cylinder block and the bottom part of the carter. The crankshaft and other details of the crating mechanism are at the same time as a reservoir of lubricant. Pallet crankcase design and designation

Pallet crankcase design and designation

The common shape of the crankcase pallet resemves a small bathroom. Depending on the design of the engine and its location in the submachine space, it may be difficult to avoid contact with the details of the suspension or transmission, for example, with the front axle reductor.

The term "dry crater" means that the oil reserve for the lubrication system is not stored in the crankcase pallet, but in the extra pochka

The main purpose of the crankcase pallet is the collection of oil circulating in the engine oil system. An additional function is the collection of small abrasive particles from the rubbing of metal parts on each other.

An excess of oil not employed at this second in the work process is collected in the crankcase pallet from where it is captured by the oil collector to allow for further circulation.

The probe is located at a short distance from the bottom of the pan and not at the bottom, so that the metal shavings and other wear products do not fall into the lubrication channels. Small particles of metal are accumulating at the bottom of the pan and can be removed from the engine by removing the pan. It is often possible to see a magnet or several magnets on the bottom of the pallet to hold the metal shavings.

In order to avoid mouldy oil and the oil from the oil pan, the pallet can be used in the bottom of the pan assembly

A cap with a threaded plug on the bottom of the crankcase is used to drain the oil and close with a metal plank with a groove and a gasket. The oil level in the pan shall be checked by means of the oil pan through a special opening in the cylinder block.

The attachment of the pallet to the crankcase is done by means of bolts through the special seal of the cap or rubber (less often, by means of a leak).

In the drain port of the crater pan, you can insert a small threaded plug for heating oil in the winter. This accessory can be found and ordered on the Internet

A successful return of oil to the area where the oil-pit is located, after being dropped from the crankshaft, provides a horizontal reflector. It has an inclined structure and is placed above the pan.

The additional function of the pallet is to protect the details of the screwshing mechanism from damage and dirt.

Cartery pallet manufacturing considerations

This is made from steel or aluminium alloy by stamping. The crankcase pallet shall be manufactured with high viscosity characteristics in order to prevent damage to the solid objects. Additional elements, such as anti-discharge curtains, lead to the bottom when the details are released from the press.

Features of the engine crankcase

With the pallet of the crankcase can be practically the only one, but a very dangerous breakage-it can be breached.

Even the most powerful and high cars are not immune to such damage. The pallet of the crankcase is the most vulnerable part of the engine, as it is closest to the road, so it is easy to pierte it by springing up a large stone or other solid object.

The pallet of the crankcase results in an oil leak from the lubrication system. This is likely to cause serious damage to the car engine, especially if the calves are not spotted on time, so many motorists resort to the crankcase pallet protection.