Hydrogen internal combustion engine, which uses hydrogen as a fuel.

History of hydrogen motors

About 45% of the world's petroleum products are used as fuel for cars. The oil reserves are limited and are not renewable, so the search for a universal energy source, which can be obtained in conventionally unlimited quantities, is definitely relevant.

Hydrogen as fuel for engines is considered among the most promising substances. Hydrogen stockpiles on Earth are practically inexhaustibles, as it is readily available from common water. The storage and transport of this gas is difficult, but feasible. And, most importantly, with equal masses, hydrogen is allocated three times more energy than gasoline.

The first hydrogen patent certificate was issued in England in 1841. In 1852, an internal combustion engine was built in Germany, running on a mixture of hydrogen and air, and Zeppelin's infamous Zeppelin diristed was installed with a light gas mixture of 50 per cent hydrogen.

The interest in hydrogen-fuelled engines resumed in the 1970s, with the advent of the fuel and energy crisis.

At the end of the oil crisis, interest in alternative energy sources has not disappeared. At present, environmental advocates fighting for the reduction of harmful emissions into the atmosphere are being intensively heated by him. In addition, the constantly rising energy prices and the desire of many countries to gain fuel independence have contributed to the continuation of theoretical and practical studies of hydrogen applications in vehicles.

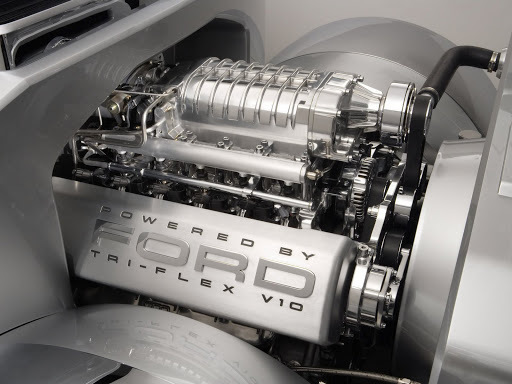

General Motors, Honda Motor, Ford Motor, BMW and others are the most active research on hydrogen engine development.

Types and operating principle of hydrogen-fuelled engines

The modern propulsion system is divided into two types: electric powered motors from hydrogen fuel cells and internal combustion engines on hydrogen.

Hydrogen fuel cell systems

The principle of fuel cell operation is based on physical-chemical reaction. In fact, fuel cells are like lead-acid batteries. The difference is that the CNG fuel cell is significantly higher than the battery and is 45 per cent or more.

A membrane with only protons is installed in the hydrogen-oxygen fuel cell. It separates the two cells with the electrodes and the anode and the one. Hydrogen has been put into the anode cell, and the oxygen is in the cell. Each electrode is plated with a catalysts, for example, platinum. Molecular hydrogen under the influence of a catalyst caused by anode loses electrons. Protons are carried out through the membrane to the katode, and the catalyst is connected to electrons (flow of electrons from outside), resulting in water. The electrons from the anode chamber are going into the electrical circuit that is connected to the engine, that is, in the domestic language, the electric current is formed and the electric motor is generated.

The current fuel cell vehicle samples are "Niva" with the power plant "Antel-1" and "Lada 111" with "Antel-2" developed by Ural engineers. The first car can be used for a single charge of 200 km and the second one can be 350 kilometers.

Internal combustion engine hydrogen

When using hydrogen in a conventional internal combustion engine, a number of problems arise. First, at high temperature and compression, hydrogen comes into reaction with the metal from which the engine is made, and even with the engine oil. In addition, in the event of even a slight leak in contact with a hot exhaust manifold, it will inevitably be lit. So, by the way, hydrogen is used by rotary engines, which are designed to be the exhaust manifold remoteness of the exhaust manifold, which makes it possible to take away the risk of ignition. However, all of these problems, including the need to change the ignition system, are in one way or another circumvent, allowing engineers to think of hydrogen as fuel-fuel-fueler.

The hydrogen for hydrogen has a lower efficiency than the fuel cell engines, but the fact that less than gasoline is needed to generate 1 kW of hydrogen energy is allowed to be accepted with a reduced efficiency.

A good example of a hydrogen-powered car could be the experimental sedan BMW 750hL, produced by a limited series and available to customers. It has a 12-cylinder engine running on a rocket fuel (hydrogen + oxygen) to disperse up to 140 km/h.

Liquefied hydrogen is stored in a special tank at low temperature. The hydrogen supply is about 300 km away. If used, the engine shall automatically switch to power from the additional petrol tank. The price of the BMW Hydrogen 7 is comparable to the value of the standard 7 and is about $93,000.

Problems and challenges of the development of hydrogen-fuelled engines

There are a number of technological and environmental obstacles for the massive transition to hydrogen as a fuel.

Production of hydrogen fuel is four times more expensive today than gasoline production.

The process of getting hydrogen out of the water is still too expensive. Therefore, the bulk of the volume is currently produced from methane. Transportation and storage are associated with high costs.

In the case of massive deployments of such power plants, hydrogen is dramatically increased in the atmosphere, which could lead to the depletion of the Earth's ozone layer, as hydrogen emissions emit much more nitrogen oxides than petrol.

The level of commercial payback of such power plants is only seen in the long run.

However, exactly the same problems occurred during the development of gasoline, electric and gas engines. It was to be hoped that the situation would change in 15 to 20 years, and the emergence of a hydrogen car on the roads would become routine.