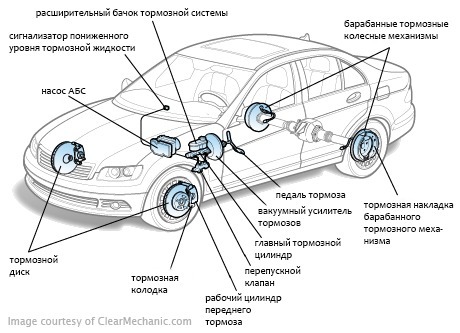

The vehicle's braking system is a key element of the driver's safety and needs to be given maximum attention. Until the breakage occurs, the driver does not need to use the services of the STA because there are standard procedures for diagnosing the performance of the brakes that the driver can do on his own.

How to inspect the braking system

For a detailed inspection of the brake system, a pit or overpass will have to be used, as many parts of the braking system are located in areas that do not permit visual inspection. Therefore, the examination procedure should be broken down into steps and carried out in a garage equipped with a pit.

Diagnosis from the salon

The first stage of the inspection is carried out without leaving the car. To do this, you need to hit the brake pedal when the engine is plugged. The pedal must be stopped almost immediately and do not move forward. This shall not give the impression of jamming.

If the pedal is "raised by a Colom" at the time of the slightest pressure, it means that it either has too short a stroke (that is, it is not able to return to the end) or it overlaps the compensation hole in the main brake cylinder.

If the pedal has a large free flow, it is necessary to press the pedal several times and if the pedal is no longer pressed and becomes elastic, it means that the air bubbles are on the system. In this case, it is necessary to look for a leak, repair the system, and pump the brakes.

To check the condition of the vacuum amplifier of the brakes several times, press the brake pedal and, having left the foot on the pedal, start the engine. If the brake power amplifier is used, the brake pedal shall "fail" at a certain distance. If this is not the case and the hiss is heard in the cabin, then the vacuum booster needs to be replaced.

Next, you should check the manual brake action by raising the lever to the up by reading the number of clicks. With correctly adjusted manual brake, the handle is raised 3-4 clicks. If the handle is raised too high, it is necessary to adjust the hand brake cable. Attention should be paid to the ignition of the reference lamp on the instrument panel when the hand brake is raised.

Then, leaving the brake pen in the raised position, it is necessary to put a neutral gear, get out of the car and try to move the car. If the vehicle remains stationary and the cable is adjusted, the hand brake pads must be changed.

This inspection of the brake system components is finished and can be opened to external examination.

Inspection of components in the engine compartment

The bonnet of the hood shall be checked for the presence and level of the brake fluid in the expansion beam of the braking system. The jaweed must be clean and slit to the top level.

If the tank is separate from the master brake cylinder and is connected to it with a hose (or hoses, if the beam with two compartments), it shall be necessary to ensure that the hoses are not leaking and have no traces of damage. If the tank with the brake fluid is located on the body of the master cylinder of the brakes, rubber seals at the place of adhesion shall be inspected.

Before continuing with the further examination of the brake system, it is necessary to remove the cover of the brake fluid and drop the plate on it, which will simulate a drop in the level of the liquid. For further action, the assistant will be required to look at the devices on which the bulb shall be lit to indicate insufficient brake fluid level. If the light bulb does not respond to the lowering, you can connect the wires connected to the connector on the cover plate lamp.

If the lamp is not lit and in this case, you should go to the service so that the specialists find the location of the break in the transaction or replace the lamp.

If the lamp works, you can continue the diagnostic and examine the main brake cylinder at the place where the brake tubes are attached. The cylinder and tube enclosures shall be dry.

Then we need to look at the vacuum amplifier housing, it must also be dry and not have any traces of rust. Place the vacuum hose and place of the intake manifold into the vacuum duct.

External wheel inspection

With visual inspection all the wheels of the vehicle shall be completely dry from the outside and inside. Particular attention should be paid to the inner side of the wheels by looking them out of the pits. Any traces of transparent oily liquid may indicate a leak in the brake system cylinder.

Observation of hoses and cylinders

In future inspection, the condition of the brake hoses, cylinder cylinders, and the visible part of the brake tubes should be visually inspected. The surface of the hoses shall be dry and without cracks. There shall be no traces of conjecture or leakage in the cylinders. The tubes don't have to be rusty. In order to pump the brakes, protective caps shall be worn. If there is an attachment of the attachment of the brake hose to the suspension, the hose shall be fixed to that arm.

Status of brake discs, drums and brake pads

Brake pads can be seen only after the wheel has gradually been removed, which is not part of the standard diagnostic procedure. It is more convenient to do this at the time of changing the wheels on the cut-off or on a scheduled maintenance service.

Checking the brakes in motion

After visual inspection, a test check should be made to check the performance of the brakes. When braking, the cylinders of both circuits shall activate simultaneously and the machine shall not be driven away.

Many vehicles identify problems with the brakes on the rear axle, but before changing the working cylinders, the operation of the coupling force control at the rear axle should be checked.