When the first vehicles with internal combustion engines were created, it immediately became necessary to have a mechanism for passing the torque from the engine to the wheels of the vehicle, taking into account certain conditions. It turned out that the car needed a idling speed and the ability to change the gear ratio for different speeds. Clutch is part of this mechanism called transmission.

To replace the clutch on the Ferrari F50, you need to detach the front of the vehicle from the rear. The operation is worth 18 to 20,000 currency units

The main transmission mechanism is a gearshift gearbox. At the dawn of the car, it could only be mechanical. It is not possible to change the gear ratio without interrupting the torque transmission. The mechanism devised to carry out this task is called chaining.

History of adhesion

The mechanisms were different for the modern clutch. One of the first inventions was Carl Bentz. On his vehicle Benz Velo, this function was performed by two connected leather belts. The driver blundered the pulley with the lever, and the clutch was flushing. A little later, an additional pulley of idle, was added to which the belt was manually moved during the parking lot. The drivers had many claims against this design. The belt began to slide. He had to be better at it all the time, almost every little bit of a handful he had to do with pullees. He had a very small resource. In 1889, Daimler, together with William Maybach, came up with conical chaining.

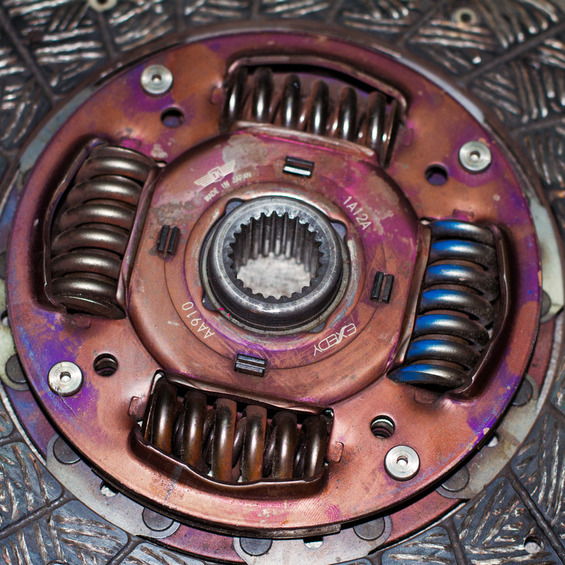

In cars with engines of over 300 horsepower, ceramic clutch discs are used, resistant to overheating in non-human working conditions

The scheme of dry one-inch clutch, which is remotely similar to the modern one, was proposed in 1904 by the French firm De Dion, Boutatton and Tripardo. The materials for the chaining disc were not invented by the French, and it was not able to transmit the torque without slip.

The modern type of clutch was given to the engineers of Adam Opel in 1965 by installing the diaphragm spring in the basket of adhesion instead of the radial springs. It has the shape of a truncated cone of a dozen elastic petals playing the role of mute shutter. This makes the clutch much softer. The further evolution consisted of experiments with materials from which the disc and basket were made, and with the construction of separate elements, such as a hymn bearing. Coupling Facility and principle of adhesion

Coupling Facility and principle of adhesion

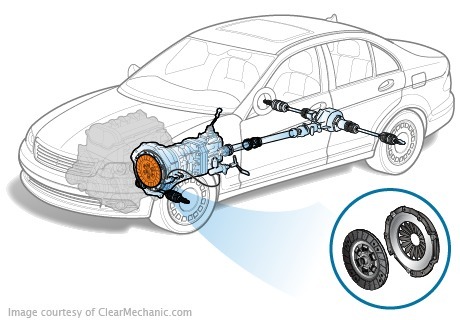

The components of the traditional mechanical clutch of all the vehicles are alike. They include the clutch pedal, the actuating mechanism (hydraulic, pneumatic, pneumatic or mechanical), the clutch, the bearings, the sub-unit known as the disc, the clutch of the clutch, and the engine's flywheel. The clutch pedal clutch the clutch pedal, push the clutch of the clutch.

The basket is holding the flywheel out of the flywheel, blurring the torque. Utilization of adhesion

Utilization of adhesion

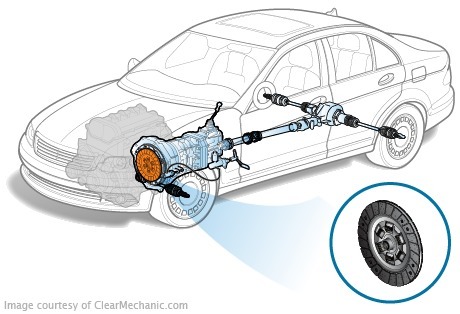

The disk resource, the most laden clutch, is at least 100,000 km of mileage. Much depends on driving habits and the driver's habits. "Burn" the clutch very fast.

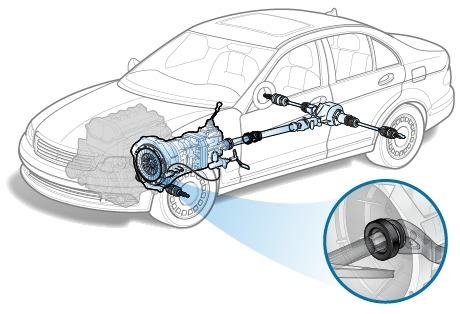

The clutch of the clutch is changing, because it's a laborious job, and if you replace the clutch with the clutch, you get a hum of hymn, then you have to take off the gearbox again. When replacing concatenation, it is necessary to check the condition of the plug for cracks and deformations.

It is more difficult to replace the clutch in the rear driven vehicles because of the difficulty of access. Top screw, clutch anchorage sometimes forced to unscrew

The main sign of the worn out disc of clutch is an unusually slow acceleration of the vehicle with the rapid growth of engine speeds, accompanied by the smell of the gari.

There are different ways to check the wear condition of adhesion. The most common is to put the car on the parking brake and slowly release the clutch pedal at the first gear by adding some gas. If the car stalled, it's all right. If he continues to work and stand still, the clutch of the clutch is raking, which means that it is severely worn out.

Further evolution of adhesion

Many manufacturers now install semiautomatic gearboxes. In this case, the transmission shall also include a clutch, although its structure differs significantly from the one described in this article.

Clutch is missing in the design of electric vehicles

A good example of such a mechanism can be a Gearbox of Volkswagen's DSG, which is equipped with double clutch, which, depending on the generation of the box, can be both "dry" and loaded in special oil in order to increase the resource and control over overheating.