The more powerful the car engine, the stronger the noise and vibrations it comes from. However, good dynamics does not always mean increased noise in the salon: to make the trips more comfortable, many motorists make a noise insulation of the bonnet.

In addition, the bonnet noise insulation has additional pros. In particular, it increases the mass of the bonnet so that it is better adjacent and less vibrating in the drive. In addition, Vibro-and noise-proofing materials act as an extra "blanket" in the cold time of the year, so the engine will take longer to cool.

Hutopulus insulation with their hands

Like noise insulation of doors, the bonnet will require vibration-proofing and soundproofing materials. It is better to choose materials that are resistant to high temperatures, as well as the foil-able layers on the surface (it will be additionally protected against heat waves). Wireservation should not be applied to the whole surface of the bonnet, but only in the gaps between the edges of the stiffness.

A layer of the sound-reflective material is placed on the viropfer (the noise absorber is not meaningful in this case). This layer must also have a foil surface that will serve additional thermal insulation.

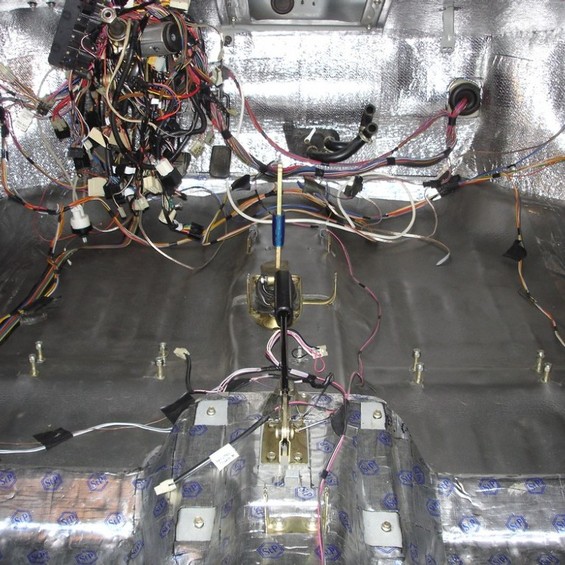

Insulation of the motor shield by the passenger compartment

In order to make the bonnet noise more effective, it should be supplemented with the noise insulation of the motor shield from the side of the passenger compartment. Of course, it is much more difficult to get to it than to the bonnet, but the effect of these actions will have a very good impact on the comfort of the train.

When choosing a vistrapfer, preference should be given to materials with a maximum of the ILC (mechanical loss ratio)-the more the indicator, the more vibrations are gone. This material must be glued to the maximum possible surface.

A noise absorber on the motor panel may be much thicker than in other places (up to 15 mm). In places where the dashboard is attached to the body (usually the upper part), you can glued several pieces of more thin material, such as 10 mm thick. By the way, in the upper part of the noise absorber will also be fought with creaks. In addition, the side walls may be taped to a more subtle material, as noise in these locations is smaller.

At the end of all procedures, it is necessary to return the normal noise insulation of the motor board. If it interferes with the torpedo installation, it can be cut slightly.