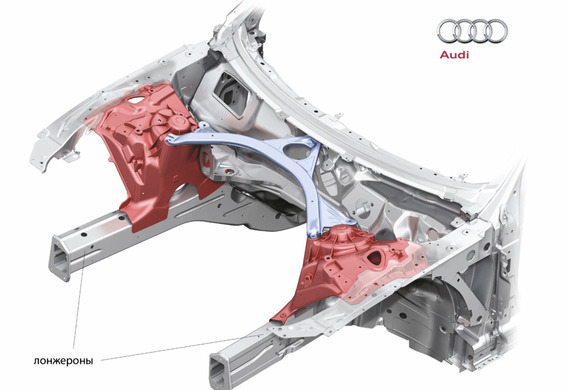

Longeron is a pipe of rectangular cross-section (longitudinal beam) which passes through the front or rear of the vehicle body (or through the front bumper to the rear). What's a Longro?

What's a Longro?

Longerons can be monolithic (constructed in the form of one part by milling or by stamping method) and composite (constructed from several elements by welding). Usually the long guys are right and left. The left or right composite extension is divided into three parts: front, middle, and rear. The front and rear are higher relative to the average, which gives the longeron the so-called S-shaped shape.

In relation to each other, the longerons may be arranged in parallel with each other (in the composition of the extension frames) and at a certain angle (e.g.

Today, the longerons are part of the construction of any car, regardless of its carrier type

They are made of aluminium or titanium alloys and steel or composite materials. The main cross-section is a seamstress (corbo-shaped box), with more cross-section height in the most loaded areas. Sometimes, at least in a small section, they may have a correlative (closed) section.

History of the Longron

The history of the longerons is connected with the history of the frame construction of the body, because initially the frames were the only car carrier. Gradually, the ramparts were improved (first they were wooden), and the frames of the frame included the longerons.

In the [ [ 20s]], Auburn creates a [ [ Long-line frame]] with a [ [ X-shaped frame]]

Around the 2020s, Auburn creates a long-term, X-shaped frame. The Longryon frames consisted of two parallel longitudinal and several mocking frames. These frames, by their appearance, looked like stairs, for which they were sometimes called stairwells. Today, the staircase can be seen by any truck, for example, by GAZeli.

The cars with the integrated frames (they integrated into the floor of the body, became part of it) were gradually emerging.

Today, the longerons are part of the construction of any car, regardless of its carrier type.

Functions of the Longron

Longeron is the vehicle's main power component: in ruminous automobiles (trucks, heavy SUVs) is part of the frame, in non-ramparts (cars)-serves as an amplification for the spray, the bottom of the body, and the floor of the luggage compartment.

The Longron carries the load of the body, the engine, and the passengers. It's one of the strongest parts of the car.

In addition, the longgers are shock absorbers on the front of the body because they are in the deformation zone. The too rigid and solid structure of the body cannot absorb the impact energy, the body practically transmits energy to the passengers. It is necessary to mitigate the impact so that a part of the body in which people are located is minimally deformed.

To this end, deformable areas shall be organized in the forward and rear parts of the body, and their power structure in the longitudinal direction is deliberately weakened. In particular, in various ways they weaken the longerons: reduce the thickness of their walls or cross-section (the variable section of the longerons), perform cross-cutting and special orifice in the areas of low-loaded places, create wrinkles which provide for a harmonic failure in the harmonica, etc. In the collision these parts are subjected to considerable destruction, but simultaneously absorb most of the kinetic energy (the energy of the moving body), thereby reducing the force of the impact directed towards the passenger compartment.

Long-pole problems

Under the influence of loads over time, the longerons may be deformed, tired and cracked. In addition, the longerons may be largely deformed after the accident.

In this case, the important parameters of the machine may be violated: the position of units (suspension, engine) relative to body, line of body parts, as well as doors and wings, the parameters of the superstructure of the body, the geometry of the suspension may be violated, and irrecoverable cracks may appear.

If the longbow is burst, the construction of the body will be completely destroyed. Therefore, after the accident, the first test is to check the extent to which the longerons are deformed and the position they are in.

According to statistics, about 90% of the work on editing and replacement of the longeron comes to the front.

Depending on the extent of damage and the length of the deformable area, the type of repair work is determined. Longeron, part of the frame, is easy to change, as to the longerons of the carrier body, sometimes it just makes no sense to change it.

If the longitudinal is not well formed, it can be repaired (extended). They do it on a special stand-up, which allows us to measure all of its parameters.

If the longitudinal is badly deformed, it is necessary to replace it, because the correction will cause a change in the metal structure to change the structure of the metal, which in turn will change the characteristics of the whole body.

With the partial change of the extension, the joints are connected to the arc welds, and no coupler couplers are used.

Since the extension of the body is a reinforcing part of the body, and is largely determined by the rigidity of the body, the repair sometimes tries to strengthen the longeron. However, if the extension is strengthened, it will stop performing its depreciating function on impact, which may have more serious consequences.