History of the braking system

Brakes were still used on the coach. The first vehicles in which the wheels of the carriages were used were inherited from them and the brakes were applied to the rim of the two sides. Similar brakes are still being used on amateur bikes.

The first disc brake engine was patented by an Englishman, William Lanchester, in 1902. Braking with copper kingfishers was heartbreaking squeaking, so the patented by Louis Renko, patented by Louis Renko, was more widespread.

The modern hydraulic braking system of the brakes was patented by American William Lockheed and was used in the cars of Walter Chrysler at the beginning of the twenty years.

At the end of the fifties, due to the sharp increase in the speed limit of serial cars, they began to install more efficient disc brakes.

In the future, the disks gradually increased in size for more efficient braking. Ventilated and perforated discs have appeared and are getting cold. The brake cylinders have also changed-the most powerful now are fitted with a multipiston cylinder capable of pinnating large areas of the pad.

At this time, the braking system is continuously improving. In order to be more efficient, the vehicles are equipped with anti-lock systems, anti-lock systems and exchange rate stability systems. All this together leads to an increase in active safety during braking.

What are the braking systems?

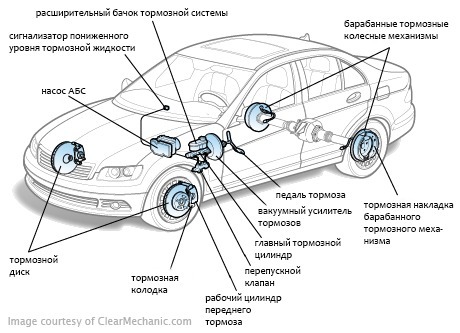

In modern passenger cars, two brake systems are installed: both the service and the parking areas. The working system is divided into two parts for security purposes. If one part of the system fails, the second one is an emergency.

The operating system is used to reduce vehicle speed.

The parking system is needed to lock the wheels during parking. In addition, the parking braking system shall be used when starting on the rise when the car can be rolled back.

How the braking system operates

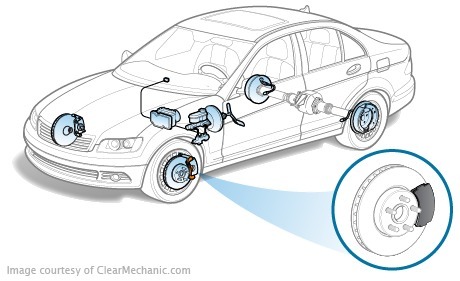

The kinetic energy of the moving vehicle extinguies, turning into the heat by friction of fixed details of the moving vehicles. The role of moving parts is played by brake discs or drums, stationary brake pads.

Operating principle of the service braking system

Operating principle of the service braking system

The pedal, the driver transmits the load to the vacuum booster. The vacuum amplifier passes the load on the main brake cylinder. The master brake cylinder shall be preset on the brake fluid in the tubes, transmitting the force to the production cylinders. Cylinders are pressed to disc (or drums). Wheel rotation is slowed by brake pads and discs, and the car stops. When the driver releases the pedal, the pressure drops and the pads are made to release the discs or drums.

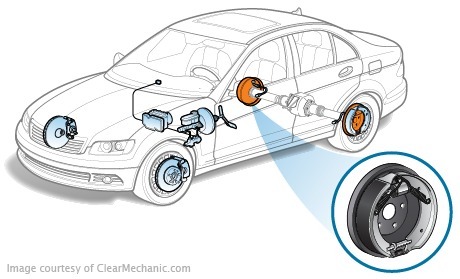

Principle of the parking braking system

Principle of the parking braking system

The driver, while in the passenger compartment, pulls up the parking brake lever. The lever locks in the raised position. Joined cables shall be applied to the mechanism by which the parking brake shall be applied. The wheels are pressed against the drums and the wheels are blocked.

Using the braking system

When braking in a car with ACPR, the box is self-transferred. The driver only remains on the brake pedal. If you have a car with the ICPC, you can brake in two ways: clutting the clutch or continuing to move. In the first case, you stop the car by friction between disks and disks. If the clutch is not open, the low speed engine helps the brake system, extinguishness of the vehicle. It's really important to brake the engine on the downhill. If only the brake system, the pad and the disc is overheated and the stopping distance of the vehicle is increased by 25 per cent. The service of brake pads and disks can be extended correctly by selecting the gear and brakes on the engine.

Interesting facts about the braking system

The brake pads of racing cars, such as the Formula One cars, need to be warmed up. The point is that the pads can operate at very high temperatures from 250 to 50 km/h. Unfortunately, it is only after warm-up at the operating temperature range that the brakes are effectively stopped.

Practically on each package with brake pads it is possible to find "Asbestos free", that is, "No asbestos". The fact is that with the friction of the asbestos filler, the dust is dangerous for the body.