The brake subport is one of the most important parts of the vehicle's braking system. The serviceability of brake subports depends on the lives of people in the vehicle. In addition, the brake sub-port is the most dynamic part of the braking system. This is due to strong competition between car manufacturers that are trying to attract potential buyers, including by increasing the maximum speed. History of the use of disc braking devices

History of the use of disc braking devices

It is believed that the first model of disc brake machine was developed by the Englishman Frederick Lanchester in about 1890. It was the first time a dry port was used in his scheme. At that time, however, there was no material for mass production of disc brakes, and the design was safely forgotten. The world's aviation industry is responsible for the popularity of the disc brakes. During the Second World War, they were installed on the landing gear of combat aircraft. At the beginning of the fiftieth disc brakes began to be actively used on sports cars, and after some time they began to install serial models. For the first time, the disc brakes were installed on the front axle Chrysler Crown Imperial 1949.

Device, operating principle and types of brake subports. The pros and cons.

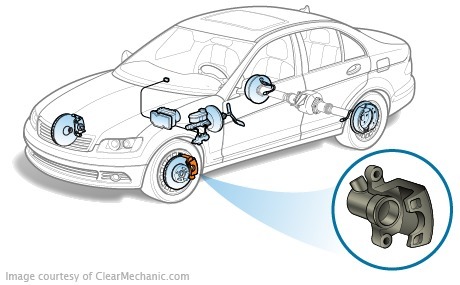

In the process of evolution of disc brakes two separate "branches" of development-the brake subports of fixed structure and the so-called "floating bracket" have been detected.

fixed-structure braking

The fixed subport is chronologically born earlier than the braking equipment with the floating bracket. A fixed-type inboard consists of a metal frame and symmetrically from two sides of the cylinder disc. The body is firmly fixed on the front or rear suspension. When the brake is pressed, the brake shall be pressed against the disc at the same time on both sides. In the condition of the pad, the pad shall be held in place by the springs of a special form. To ensure simultaneous operation of piston, the brake fluid shall be fed by a ramified system of tubes simultaneously in all cylinders. With multiple cylinders being used, fixed brakes are very efficient. They are placed on vehicles with a large mass (e.g. Mercedes-Benz G-class W463) or sports cars. Such devices are manufactured by specialized sports spare parts companies, such as Brembo.

Floating-bracket (floating)

This type of braking system is different from fixed points, which on one side of the pad is always in one place. A floating bracket consists of a bracket and a cylinder casing fixed on the inside of the wheel. There is one (less than two) piston in the cylinder casing. When braking, the piston is placed on the second pad in front of it. Thus, the pad begins to move, and when it is pressed against the plane of the disc, the floating subport moves towards the piston on the guide fingers, causing the brake disc to press the second, outer pad.

This type of mechanism is simpler, cheaper in production and has a small size. This type of brake has been made available in low-cost golf-class cars equipped with small-diameter established discs.

Issues of operation and modernization of braking supports

It is important to know the order of service of the car's brake system.

1. At least once a month, the components of the brake system, including brake peptports, shall be inspected for brake fluid flow. When inspecting the brake sub-ports, attention shall be given to the piston dust of the working cylinder and the connection between the hose and the dry port. If traces of the subflows are found, it is urgent to find their cause and eliminate it.

2. At least every two years of operation of a car completely change the brake fluid in the system. Since it has such a property as hygroscopic, the ability to absorb moisture from the air. The presence of water in the brake fluid is, first of all, the braked and undocked brakes, and the second is that the connections of the brake system and the hoses of the braking system are not disconnected-due to the appearance of corrosion signs. The delayed replacement of brake fluid may result in piston in the working brake cylinder. The cylinder has to be replaced in order to correct this problem.

3. All modern brake pads are equipped with wear detectors. When you replace your pads, you should pay attention to the amount of wear that you wear. If the wear is uneven, the guide fingers of the floating bracket are likely to be sour. To correct the problem, you need to replace the lubricant and develop the guide rail.

Upgrades

Replacement of brake subports to more productive-natural prolongation of the car's tuning if the first step was to increase engine power. To strengthen the braking system of a motor vehicle, the regular support is usually replaced by a seaport with a large number of cylinders or a sub-port with a larger diameter of the working cylinder. Such interventions tend to occur in pairs with the replacement of brake discs with larger diameter discs and improved ventilation. The brake subports with 4-12 piston engines create a much larger pressure load that is evenly and optimally distributed across the area of the pad. At the same time, four pets per sub-port are required from 8 to 12 piston ports. After you replace the subports, you must check the performance of the system on a special diagnostic stand.