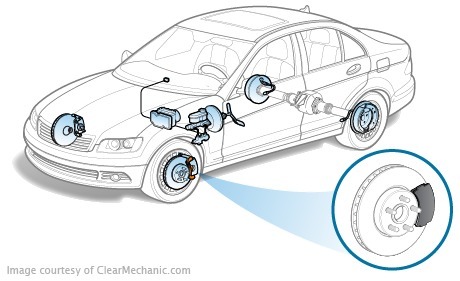

Brake pads are the service brake system. With the help of the headband and the discs they contact, you can reduce the speed of the car to a full stop and keep it in place. Boats reduce friction by friction. Brake pad device and operating principles

Brake pad device and operating principles

The boat is made up of friction linings and the carcass. The laying is in contact with the surface of the disk, so its main characteristic is called the friction coefficient. The ratio is 0.35 to 0.45, but the average rate is 0.35 to 0.45. These figures are used by manufacturers to calculate the optimal conditions for safe braking.

Ferodo is continuously looking for ways to improve the quality of vehicle braking. Ferodo Racing DS3000, with R-comp filler linings, can slow down 50% faster.

The material from which the pads are made shall be strong and resistant to high temperatures, as a large amount of thermal energy is allocated during heavy braking. The material from which the molding is made can have more than a dozen components-each manufacturer has its own recipe. However, the basis for the mixture is a substance with an effect: it was asbestos at an early stage of development, until its harmful properties were found. At the moment, the reinforcement of friction particles is used by the organic compounds on an organic basis.

Asbestos and non-asbestos-pad

Asbestas was popular, mostly because of its low cost. However, doctors found that asbestos dust was harmful to the health of not only the driver but also pedestrians on the road. Even when replacement of brake pads with asbestos is replaced, the use of a decorator and eye protection glasses is recommended.

Asbestos carcinogenic effects of exposure to asbestos are proven by physicians and accepted by the world

The badass component is the so-called steel wool. More complex polymer compositions are often used in production. The linings of more expensive shoes include impurities from soft metals (such as copper shavings), carbox-new fibres and gravel of artificial graphite. This mixture not only has excellent friction properties, but also increases the thermostability and durability of the pad. The use of soft metals provides a low level of noise during braking.

Advantages of disc shoe

An image of the disc braking system by an Englishman Lanchester at the end of the 19th century allowed for an order to increase the reliability of the brakes and the speed of their actuation. However, the boats that were used in it were made out of steel, as special friction liners did not exist at the time. Steel swarves, iron tubes, heartrly squeaking. Part-time for this reason, Lanchester's invention was forgotten before the middle of the twentieth century, and the vast majority of manufacturers had equipped their cars with drum brake mechanisms.

The ceramic pads, which used to be the autoport attribute, are now considered the most effective under any conditions. As of 2012, more than half of the new models are bundled

The noise problem is solved in the production of modern hard disks. If the pad is creaked, they are either not yet wiped out or made with a technology violation. Most often, "creaky" beads are counterfeit goods.