The operation of the hydraulic braking system is not possible without the brake hoses. The quality of the hoses is a guarantee of the safety of the driver and passengers, as well as the operating hours of the system, so the regular check of the integrity of the hoses is very important. Braking hoses on first vehicles

Braking hoses on first vehicles

Prior to the invention of the hydraulic braking system, the mechanical tether drive was quite widely used-where the brake pedal force was applied to the wheels with special cables. The main lack of the system is the high exposure to pollution and rust, as well as the need to make great efforts to stop the car.

Because the brake hoses are an integral part of the hydraulic brakes, they were invented at the same time. Malcolm Lockheed, who invented the hydraulic braking system, had special hoses for each wheel. With the pressure, the hydraulic hose was fed into the dry ports and the brake pistons pressed the special pad. The first brake hoses were made of rubber.

For the first time, the hydraulic drive with the brake hoses was installed on the car of the American company Duesenberg in 1921. The upgraded system installed Chrysler in 1924 and then used General Motors and Ford.

Hose hoses

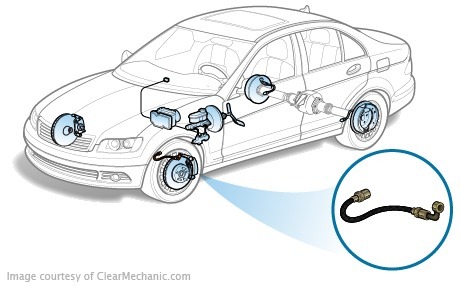

The main function of the brake hoses is the transmission of the pressure that occurred inside the system to the cylinders. Cylinders affect brake pads.

The brake hoses are constantly pressurized, so the integrity of the structure is particularly important. The brake hoses consist of a high pressure arm and two attachable spiners. Usually in the brake system four hoses are two for the front brake cylinders of two to the rear.

Types and materials

Generally, manufacturers represent two types of brake hoses: rubber and reinforced.

The rubber hoses are just at first sight. They are actually quite reliable and consist of three parts. The internal rubber coating of the hose is securely holding the brake fluid inside. The next surface is a steel net that does not allow hoses to deform under pressure. The third layer is a thin rubber coating that provides flexibility and resistance to hoses. The rubber hoses are fairly resistant, but they are considered to be slow. This is because they are slightly more susceptible to pressure deformation than arminated.

Reinforced hoses have two layers: an inner-plastic tube of enhanced strength, and an external-special metal network. It is this network that does not deform the hose, it has a different structure than the hoses of the rubber hoses, and is considered more reliable. This design of the hoses is considered to be more effective in controlling the braking process. Minus the hoses that the arminated surface claws all around. Therefore, many manufacturers have started to deliver a transparent third layer of PVC on the hoses.

Monitoring and replacement

Periodically inspect the brake hoses. You must perform diagnostics if you notice:

- Leaking of brake fluid;

- cracks and damage on hoses;

- Violation of the leakproofness of the coupling points.

The service life for the hoses is set by the manufacturer. Normally, the service life does not exceed 100000 km of mileage. The replacement of the brake hose may be required earlier if the vehicle has been used in extreme conditions. Do not ignore the replacement of the hose on time, otherwise it can burst and provoke an emergency.