One of the main enemies of the car is rust. The metal that your car is made of is subjected to a daily negative environmental impact, which may end up with corrosion. Sometimes it is not enough for a staff anticorrosive protection, which is done at the factory, and then the owner is thinking about making additional corrosion treatment with his own hands.

In fact, anti-bark is not that difficult, and many motorists are handling this procedure. The most commonly used hand is the anti-corrosion treatment of the bottom, as it is the most affected by the operation of the car. In addition, the interior of the passenger compartment, luggage compartment and subspace shall be treated as well as all the welded seams and curvature of the body.

What materials are needed to make the antimatter with your hands

All necessary materials must be kept in stock before starting the anticorrosive process. It is not necessary to make the anticortex yourself, as the Soviet motorists did: today there are many ready trains in shops that will perfectly protect the machine against corrosion.

Note that you will need two kinds of anti-cortical anti-cortical cavity and exterior surfaces for fully corrosion-resistant processing. It is not necessary to break this separation and save for the purchase of corrosion-resistant trains because they differ in their properties. The antique for the hidden cavities pushes moisture and allows the surface to "breathe" and, for external surfaces, is more resistant to mechanical damage.

If there are already early signs of corrosion on the surface being treated, you will also need a rust converter to be applied before corrosion begins. It is better to buy a rust converter on a zinc basis: it has a good reputation among motorists.

How to Make the Car Anti-Corrosion Control with Your Hands

Before beginning corrosion-resistant processing, the surface must be thoroughly prepared:

- Carefully wash the surface with warm water and dry out,

- if the bodies already have rust hotbeds, process these places with rust transducer and allow for a few hours (more precise time is indicated on the means).

To process the anticrust, it's best to drive the car over to the pit. The wheels and the shelvings must be removed from the car (pay particular attention to the longerons, which often become a source of corrosion).

For the anti-corrosion treatment of the passenger compartment and the boot, you need to remove everything that is possible. The food should be closed, as their surface would be slippery and slippery, and it was not safe during driving.

When handling the anticortical compartment and the engine compartment, ensure that the substance does not fall on the generator, the hundredth of the radiator and the straps.

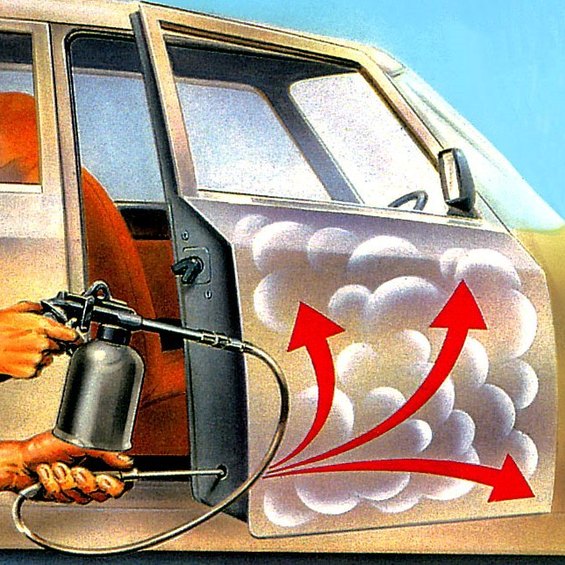

Nanning the anchor should be a brush or a sprayer. Special attention should be given to cavities. To fill in the anticortex, you need to use a special, flexible spray nozzle: inject it into the cavity through the process hole and spray the substance inside.

The welded seams of the body shall be treated with particular care.

After all surfaces and hidden cavities are processed by antimatter, do not touch the vehicle for several hours. Review the instructions for the anti-corrosion formulations to determine the exact time of their drying up.

Note that even the most careful and professional corrosion resistant car processing does not guarantee 100% protection against rust. If any damage occurs, it should be removed immediately to prevent further oxidation and corrosion.