History of multi-hour suspension

The pioneers of a serial vehicle with a multiple-horseback suspension were the engineers of Porsche. In 1979, for the first time, a multi-horseback rear suspension appears on the 928. The solution was simple as all geniality: to prevent unwanted movement of the wheel in the longitudinal direction, they added two support levers to the already existing structure.

In 1982, such a scheme was implemented at Mercedes-Benz 190. Compared to the Porsche 928 suspension, it was a serious step forward. Engineers "have taught" the rear-loaded wheel to turn inward, that is, to make friends with the front wheels. Thanks to this car, the car was going "like on the tracks".

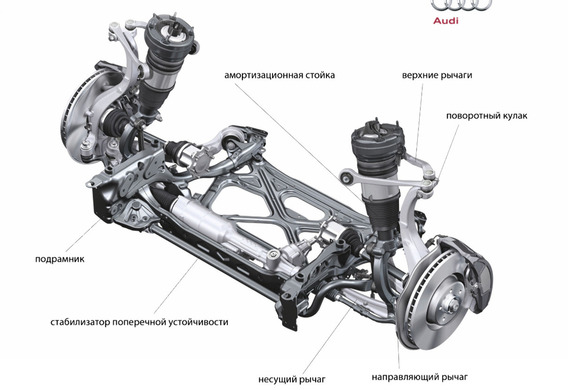

Multi-side suspension design

Each lever of the multi-board suspension is attached to the hub of the wheel through the ball support leg or cylindrical section, and the other to the imitation or extension unit through the same cylindrical section. Some constructions use the irritation levers, as in a two-track suspension, attached to the body or imitation in two locations. In the vast majority, the mounting of the levers of the rear axle is used to give the entire structure stiffness.

A large pendant may be placed on the front axle of the vehicle, but most often used on the rear axle

In the front suspension, the longitudinal levers are often replaced by reactive propulsion, which simultaneously performs the function of the lever and partly stabilizer of the stability.

A large pendant may be placed on the front axle of the vehicle, but most often used on the rear axle.

At the base of the multifir suspension is the time-tested suspension of the suspension scheme on the two transverse levers. The primary load function is the lower arm. When the suspension works, it is loaded the most. The upper lever for the two-lever construction is generally a forked construct. Two-side suspension has one significant drawback. If you start braking at the turn, the levers work on the curve. The wheel on the outside is rejected by a few degrees. This causes oversteer, which can lead to a sharp failure in the vehicle.

This shortcoming led the engineers to design the construction with two levers instead of one, thus making the general design more elasticity. At the same time, in a generally accepted multi-lever system, the two levers have been replaced by a lower lever, not the upper lever, and fixed to the hub, ensuring its stability in the horizontal position. The levers are attached at various altitudes and one of them, the auxiliary (front), also performs the adjustment function.

The longitudinal levers shall ensure the steady position of the step in the longitudinal direction, without allowing it to be moved forward or backward.

Further development of the multi-board suspension

The rear wheel transfusion described in the Mercedes-Benz 190 sample was passive, that is, depending on the wheel load. In the future, the engineers who worked on the creation of premium brands went on. For example, BMW specialists were the first to apply an active back suspension. In addition to the five levers, the steering forces, which are used by electric motors on the computer's command, are connected to the hub. Depending on the settings chosen-from comfortable to sports-friends may be excessive, neutral or insufficient.

Pros and cons of multiple suspension

The positive side of the multifir suspension is hard to overestimate. Due to the use of the sailers in all the levers and the kinematics of the suspension, we get a great flyness of the move. But the most important virtue of this suspension, of course, is manageability.

The large pendant is demanding for road quality and is worn out fairly quickly on Russian open spaces

But you have to pay for the pleasure of the trips. Such suspension is exacting to the quality of roads and in Russian spaces is worn out fairly quickly.

In accordance with the concept of modular node replacement, most manufacturers position the levers as applied in the vehicle's suspension as non-selective. The cost of leverage is generally high. Accordingly, the bulkhead of the whole suspension shall be circular. There is a possibility of saving some of the money, but some research will have to be done.

As a rule, manufacturers of universal parts of suspension, such as saintblocks and ball supports, make spare parts of all sizes and sizes. However, in order to find the right site blocks for all the levers of the rear suspension of the same Mercedes-Benz, it will be necessary to carefully examine not one catalogue.

Multi-horsework suspension

It is not difficult to diagnose the condition of the multi-sign suspension independently, despite the complexity of the construction. To do so, it is sufficient to reduce the right wheel and with the help of a tire iron, plunting it into a gap between the prowler and the edge of the site (or between the step and the lever, in the case of the ball support), to shake each lever. "Living" Sciententblock should not have a play. If a worn lever is located, the replacement is not to be pulled, because this changes the angle of installation of the wheel, resulting in premature and uneven tyre wear and driveability.

As a result of the complexity of the construction, it is important to remember that the back of the high plate, like the front, often requires checking of the collapse and ascent. Both of these parameters are regulated both on the front and on the rear axle of vehicles fitted with this type of suspension.