The rudder reducer is one of the oldest mechanisms in the construction of the car, which was used in the steering control at the beginning of the car construction.

The steering gear is a mechanism that is carried out in the shape of a separate machine and consists of the jagged wheels and, depending on the design, the worm shaft. The main objective of this unit is to increase the driver's hand. The driver may turn the wheels of the vehicle in the right direction without significant service, even if the vehicle is not equipped with a steering amplifier.

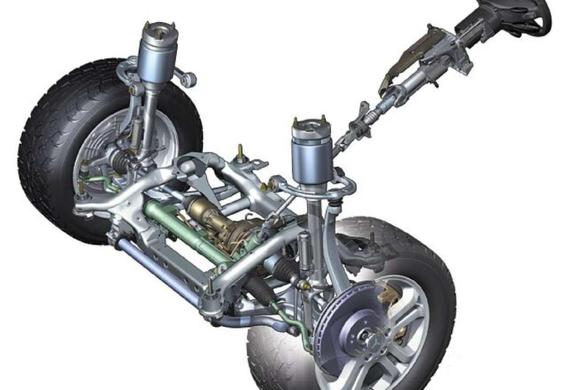

Steering gear reducer unit and operating principle

All reducers have a hull made of cast iron or welded steel. The frame is equipped with gear-wheels, shaft, bearings, etc. Occasionally, the gear casing may be used to lubricate the bearings and cordon.

Many varieties of gearboxes are known to date. They can be classified by type of gear (worm gear and jagged); type of jagged wheels (conical, cylindrical, cylindrical); by number of steps (single stage, two-stage, etc.); depending on the characteristics of the kinematic scheme (with an expanded somatic outline or with an upper level), depending on the location of the vales (horizontal, vertical).

With all the variety of constructions the most common cars are equipped with magically reducers. These reducers transmit the torque by means of a worm gear, the main elements of which are the screw-worm and the worm worm wheel. The worm gear is currently used in all helmsman reducers.

The worm is a special screw made of solid materials and has a trapezoidal form of the thread profile. The outer wheel is very similar to a common jagged wheel, but the carvings on this wheel have been carefully set under the shape of a conjugated worm. Typically, the jagged wheels for powerful gearboxes are made of two different materials. The raw material for the heart is any inexpensive and at the same time strong steel (or common cast iron), and the skillet is made of high-strength, antifriction materials. Due to its design worm gear is effective in devices that require a high torque combined with a low angular velocity.

Pros and cons of the gear reducer

The advantages should be the effect of self-rejuvenation, a large transmission ratio thanks to the use of only two parts, low noise and the easing of the move.

The drawback of the worm gear is the increased wear, heavy heat due to friction, squatting, and relatively low efficiency. To prevent malnutrition and fast wear, you must adjust the mechanisms and comply with the accuracy requirements of the assembly.

The main advantage of a worm gear before the jagged is that the initial contact of the links occurs along the line rather than at the point. The input and output shaft in the gear reducer of the worm type may be crossed with different angles (more often than 90 °). An important advantage is that in the same ratio, the worm gear occupies a much smaller place.

Steering gear-related issues

Any unit will fail sooner or later for various reasons and, of course, the gear reducer is no exception.

Most often, motorists collider with the problem of the steering gear. This breakage is quite easy to detect visually since the main symptom is the presence of oil under the car. This may be due to both the corrosion of the primary shaft and the calcine. In the first case, it is necessary to polish the shaft, and then it is necessary to produce the gas-thermonopture to the desired size. In the second case, new gaskets, cuffs, and sappers will have to be delivered during the repair.

Another problem is the sudden feeling of the rudder steering. This feeling is due to the increased effort to steer the steering wheel. In order to ensure that the repair of the rudder is necessary, it shall be necessary to measure the steering effort of the special dynamometer. The results shall be compared with the vehicle manufacturer's data. If the results do not comply with the standards, diagnostics must be performed on the special stand. This will help to determine the flow rate, the pressure of the fluid, and the presence of its transmission in the steering gear. Do not attempt to repair the rudder on your own. It's a lot better, more reliable, and it's easier to hand it over to the workshop. Or, if the funds allow, simply replace it with a new one.

The problem of the play on the steering wheel is also often met with breakage. Such a defect may be the consequence of a failure of the cross section of the steering column, but may be a sign of the movement of the rudder directly. This breakage requires the complete disassembly of the device, the examination of the condition of the elements and the replacement of wornable parts. After finishing the work, the device needs to be adjusted on a dedicated stand.

Also a common problem is the knocking at the gearbox. Such a failure occurs due to the wear and tear of the bearing bearings.