The lever is the independent suspension of the car. Used to ensure a limited movement in the vertical plane of the wheel, which it holds on the ground, preventing it from falling away. Types of suspension levers

Types of suspension levers

Depending on the design of the suspension lever, the levers shall be divided into types by the number of attachment points. They are also classified according to the angle of the vehicle heading. On this parameter, the levers shall be divided into longitudinal and transverse. Most often, the independent suspension meets the A-shaped levers (also referred to as triangular levers), direct levers with two attachment points and H-shaped levers, which are two pairs of simple levers that have a common jumper.

Design of the current suspension lever

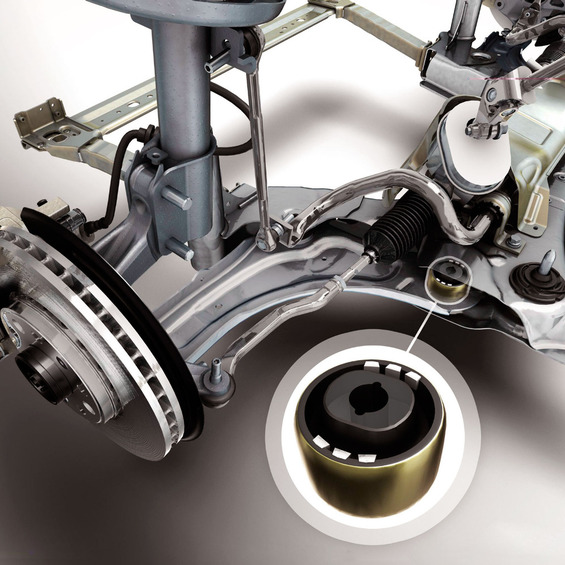

The lever is a elongated elongated piece of light alloy with stiffness in the longitudinal direction and the tides at both ends. One end is fitted with a cylindrical receptacle in which it is inserted or more fitted to the cylinder block when the component is attached to the body, frame or imitation. The second end is fitted with a ring-shaped tidal, which is the fastening of the ball support leg. The design of the lever may vary depending on the engineering decision of the suspension. For example, the tides may not be placed under the ball support, since it is done on the body of the ball support itself, which is attached to the lever by means of bolts and nuts. In addition, the levers with cylindrical bosses at both ends are often used in the rear fallow suspension.

The pioneers of steel levers were Volkswagen and Subaru, which started to actively use light alloys in the suspension of their cars back in the 1990s

In the suspension of vehicles made before the early 2000s steel levers were generally used. In doing so, they may be either a hollow box structure (so-called square pipe) or a structure with three walls, two of which serve to the ribs of rigidity (so-called a seamstress). In the more modern designs of the suspension, there is a tendency to gradually phase out steel, in order to reduce both the overall weight of the car and the unoccupied mass. The pioneers of steel levers in the mass models were Volkswagen and Subaru, which started to actively use light alloys in the suspension of their cars back in the 1990s.

Suspension of the suspension lever

The purpose of the suspension levers is most often dependent on the location. The lever may be transverse, longitudinal, upper and lower. Depending on the location, they perform different functions.

The main feature of the triangular lever is that it operates in both the transverse direction and in the longitudinal direction

For example, the task of the upper front suspension lever is to hold the upper part of the fist without allowing the wheel to be attached to its side during movement. The lower arm also partially performs this function, helping the upper one, but it also controls the bottom of the McPherson rack without allowing it to rock. The longitudinal levers are most often used in the rear design of the rear suspension and serve to keep the rear racks in one position during acceleration and acceleration when they are actuated by forces along the axis of the vehicle's motion.

Features of the triangular levers

The construction of the triangular lever arose during the process of creating a simplified suspension for inexpensive cars. The main peculiarity of the triangular lever is that it operates in the transverse direction in which it is installed and in the longitudinal direction. With three anchorage points (two fixing points to the body, one for attachment to the shell), the lever can hold the cushioning counter in both the transverse and the longitudinal direction. This design has made it possible to use fewer parts in the suspension, making it cheaper. That is why the independent front suspension on triangular levers is so popular.

The operation of the suspension lever

In general, the suspension lever is an unassuming and durable detail, especially if it is made of steel. Steel levers, as opposed to light-alloy, are suitable for several cycles from repair to suspension. When the lever is repaired, the ball shall be replaced by the ball support and the site unit (or the two sailers in the case of a triangular or simple longitudinal lever) and the part itself is sent to the second or third term of service. Easily-smooth levers are, in most cases, to be replaced in their entirety, which increases the cost of suspension, although it makes it slightly simpler.

Two factors are usually the reason for the release of the lever: mechanical corrosion and corrosion

The reason for the release of the lever is usually two factors: mechanical impact (hitting a pit, a road accident) resulting in a deformation of the lever, and corrosion which, by the way, is not easy to use.