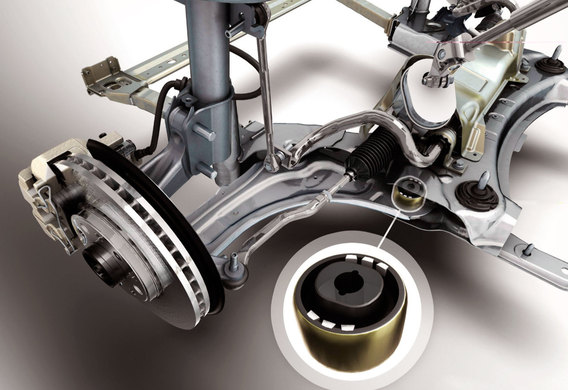

The SilentBlock provides the flexibility of the suspension elements relative to each other and the absence of a creak from the friction of metallic parts. It consists of two beetles with a rubber gasket. It is thanks to this pendant box that the fluctuations that are transmitted from one part of the suspension to the other are gone. The role of this feature is extremely important because most of the load is on it. Simply put, the site softened the blows that come into the body and extinguishes the vibration in the suspension. Site Unit

Site Unit

In the front suspension, the side-beams are used to connect jet traction with the body and levers, and in the rear suspension-to fasten the pole.

The elastic insert between the sides of the site is rubber or polyurethane (synthetic rubber substitute). The main advantage of polyurethane is that it is stronger and has a wide range of characteristics: for example, it is less subject to ageing and environmental impact. This material has been actively used in the automotive industry in the 1970s. Then the motorsport engineers were obsessed with the idea of improving the suspension mechanism and the steering gear. And the polyurethane the rubber has come to help them.

The polyurethane sides have a number of advantages over rubber

In the process of manufacturing site blocks, a polyurethane of 65 to 70 Shore (the method of determining the hardness of materials, the height that after the impact bouncers off a special bade from a certain height) is used.

The polyurethane sides have a number of advantages over those in the manufacture of which rubber is used. First, they retain the suspension geometry and control of the control, no matter how the car is operated. Second, the original details are slower to wear. Third, the suspension becomes more resistant to the effects of various kinds of liquids-from water and gasoline to regents and acids.

Of course, polyurethane sites are more expensive than those with rubber, but they will have to change about four times less.

How often you need to change the site blocks

The Silentblocks, on average, are up to 100,000 kilometers of mileage. However, domestic roads are known to spare cars, so the Russian motorists are advised to inspect the Sailentbots twice as often as every 50,000 kilometers.

It is important to evaluate the site side by several criteria: it is not cracked whether it has no abrasions or noticeable bubbles. Special attention should be paid to the loft in the site blocks. If there is a pounding in the suspension, the most common reason for their appearance is the dilapitness of the Scientblocks that result in the appearance of the people. If one of the listed signs of wear is observed, the sainsides need to be changed. The best approach is to refer to the master, as they will require a special tool for repressing and a certain style.