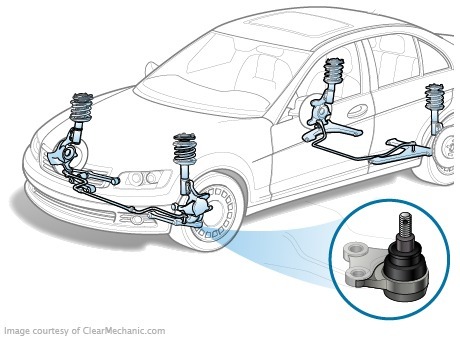

While moving the front, driving, the wheels of the car perform two functions: drive the car on the road and allow manoeuvre, that is, to turn to the right or to the left. Several requirements apply to the wheel position for manoeuvring and manoeuvring road traffic: the wheels shall be flat, roll forward or rearward, easy to drive and securely fixed. These conditions shall be met by suspension, and the ball support in it shall be maintained by combining the levers of the steering wheel with the steering wheel hub. Tale of ball support

Tale of ball support

The ball supports were invented and used as an alternative to the kingpin mechanism. Initially, the ball supports were used only in the front suspension structure and provided the vehicle's wheels turning around the vertical axis. The standard design of the ball support, which remains practically unchanged and today, was developed by Italian engineers for Fiat more than 40 years ago.

Device of ball support

Technological advances have resulted in changes in the original ball support device, although they were not of a fundamental nature. The strains of the shell, which are connected by a spot welding, have been replaced by the supports of the cast and the lavatory-with a threaded cover, unserviced and serviced-with Press-Maslenitsa. These improvements have been justified and useful. Today, the structure of the most common unserved ball support consists of: body with spherical hand and finger with a ball at one end and carving on the other. The Pyrnik, with a finger on the finger, prevents moisture and dirt from getting into a filled, special thick lubricant enclosure.

Main function of ball support: to ensure that the wheel has a fixed horizontal position during the vertical movement of the wheel. The ball finger can rotate in the body, rocking small angles. That is, in the plane of its attachment the ball support is provided by simultaneous rotational and linear (limited) movement of the finger.

All the details of the ball support leg are normally made of steel. To reduce friction between the working surfaces, the spherical depression of the shell covers plastics or other polymer material. However, there are ball supports which do not include polymer coating between body and finger. This applies, first and foremost, to obsolete domestic vehicles. The models were equipped with a sampling pylon which removes the covers of the lift cover.

There are two ways of fastening the supports. In the first case, it is bolted to the lever. In the second, he's stalking him. When the ball supports the ball support bracket, it can be replaced by a single node. To do this, simply buy and install it by bolting the bolts to the lever. In the second case, it will be necessary to change the suspension lever with a pre-defined, shuffled ball support. The cost of such repairs is significantly higher since it includes the cost of the lever.

The shuffled supports shall normally be mounted on Japanese motor vehicles. Asian auto parts manufacturers offer the consumer the ball support for such cars as separate components. It is much cheaper, but it should be recognized that their quality is significantly inferior to the original, and the lever will have to be converted into an "craft", turning it into a detail that is not subject to warranty repair.

Operation of the ball support leg

The ball support, for its purpose, has been operated in hardline. The main mass of the car is based on a very small surface area of the ball. And, given the weight of passengers and cargo in the passenger car, high speed and poor roads, it becomes clear that the load on the ball support is multiplied. This inevitably leads to the wear and tear of this node.

According to some data, the volume of Russia's ball support market is more than 20.000.000 pieces per year. About 70% of this amount is a ball support for domestic cars and more than 20% for foreign cars.

It is recommended that you give preference to the original manufacturers when you purchase this loaded feature. The market is represented by a large number of brands that produce analogues of original parts, including the ball supports, but only well should choose well. Production facilities and experience enable Russian plants to provide the necessary quality level. The result is more reliable and robust supports, which are not inferior to foreign analogues and meet all safety requirements.

Number of ball supports in the suspension

The most common one is the front suspension with two ball supports, one for each wheel. Some vehicles-in particular SUVs-have four ball supports on the front suspension, two (upper and lower) per wheel. Far less frequently, the front wheels have three ball supports. Modern automobiles with an independent rear suspension are often fitted with ball supports and rear wheels.

The higher number of ball supports provides them with a long service and reduces the risk of failure. But this complicates the diagnosis of the suspension of the car and significantly increases the total cost of repairs and spare parts.

Diagnosis and replacement of ball supports

If a driving force is required to do extra work or a creak, there may be a problem with the ball support. This is also said by the formation of a knocking at a small speed on a rough surface, for example, in the passage of a "leach police officer".

Another sign of failure of the ball supports is the volatility and evilation of the front wheels while the line is straight. Another characteristic sign of problems with ball support is the uneven (lateral surface) of tyre tyre wear.

Of course, only professionals can make a quick and qualitative change of ball support, although many car owners prefer to do so on their own.

Today, the production of ball poles is a high-technology process that allows for a high degree of reliability. However, their replacement is the most common type of car repair. The situation will not change until Russian roads are qualitatively changed.