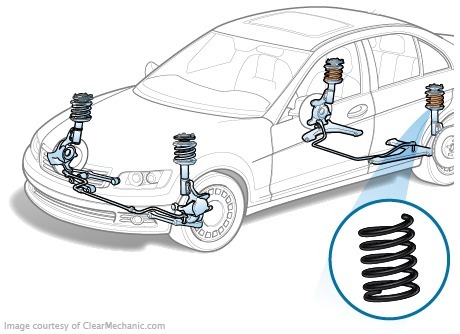

The spring is the elastic part of the spring suspension, which provides the body with the necessary height, insulates the car from the roughness of the road, improves the comfort and the capacity of the car. The springs regulate the shock absorbers. In modern cars, wine springs are used.

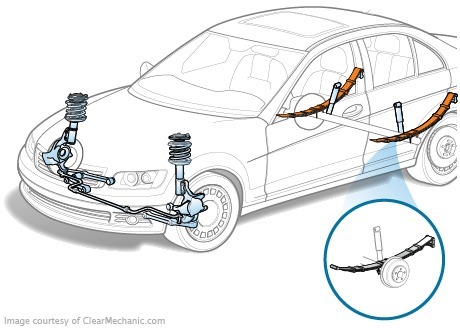

The first signs were still in the cart and the carriages, as it was about the comfort of transporting people and goods before the invention of the car. The suspension on the springs was invented in the 19th century, and it was used in the first cars. This kind of suspension existed in cars and trucks until the 1950s.

When it became clear that the springs did not provide the desired characteristics, a peat (twirling rod) was used as the elastic element. One of the ends of the torcione was fixed on the body or the frame of the car and the other on the suspension. Under the pressure of the body, the rod is twisting and ensuring the desired melting.

The pendant in the suspension appeared as a logical continuation of the torsion. It is a long cylindrical rod, curled along the spiral. Compared to the torcions, the springs were more comfortable in service-it was easier to mount, it could provide a progressive increase in elasticity, the driveability of the car improved. The spring suspension was invented in the 1930s, but only in the 1950s.

Suspension supprescience

The ability of springs to resist compression is called stiffness is the basic characteristic of spring.

Prepare springs from special torsion steel which, during deformation, tends to return to their original position. The custom-made absorber is usually located inside or near the springs.

The main functions of the spring are to maintain the weight of the car, reduce the vibrations and impact from the road surface on the body, maintain good grip on the road and maintain the correct clearance (the ground clearance).

The words "soft suspension" and "hard suspension" are known. Such suspension characteristics are also dependent on springs. What should be the right spring? There is no one-digit answer. The manufacturer shall optimally stabilize springs, depending on the size and characteristics of the car.

Too hard a spring makes the driveability of the car uncontrollable, increasing the discomfort of passengers. Too soft absorbts the surface unevenness efficiently, but it gives you a big roll of car on turns.

The stiffness of the spring depends on:

- The diameter of the rod. The larger the diameter, the greater the stiffness;

- Outer diameter of spring. The diameter of the spring is smaller;

- the number of springs. The larger the turns, the less stiffness;

- springs. Different forms can change the characteristics of the spring. It is a cylindrical, conical, booky shape of spring. Also, one spring can combine several forms.

Types of springs

Depending on the functionality, several kinds of springs are different.

Standard. These springs are designed for ordinary urban cars, their hardness is usually medium. In the case of failure, they are replaced by the same.

Reinforced springs have high stiffness, making them out of a larger diameter. They are installed on vehicles whose rear axle is subject to heavy loads. These are vehicles that often carry goods or are used together with a trailer. Reinforced springs work in the same way as standard loads, while increases in load stabilise the body and help maintain the driveability of the car.

The springy springs. They are used when you need to increase the ground clearance, make the car higher.

The lower springs are capable of reducing the centre of gravity of cars, which helps to make driving more dynamic and improves driveability.

Variable-stiffness. Their construction (cross section of the rod) allows the rigidity to change depending on the road situation, which provides the car with smooth progress under any conditions.

Pruzhin is often made for purchase.

Monitoring of the springs

If the suspension of the suspension is not replaced in time, it may affect the suspension of the suspension and other parts. The nose of the springs is due to metal fatigue and its gradual corrosion. The spring breaks or it settles. When making springs are covered by a special anti-corrosion coating, it loses its properties over time. The average service life of the spring is three years. The replacement may be required earlier if the vehicle was carrying heavy loads or travelled on bad roads. The state of the spring is checked at each TVE. The inspection shall include an external examination of the rust and breakage, as well as the measurement of the height of the spring, to see if there is a screening.

Specialists advise the installation of new springs on the axis-springs must have the same characteristics-it guarantees the same height of body and excludes movement skewed.