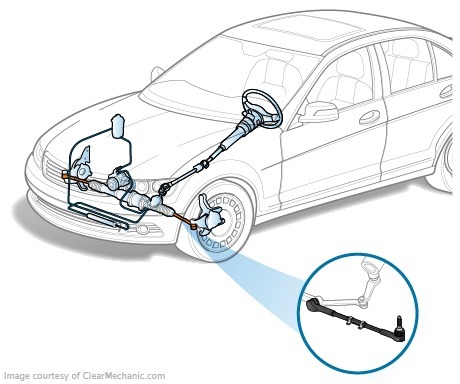

Depending on the design, the components of the steering control may have a shtotype with a threaded connection of either side or joints with one or two ball joints. Heavy with two connections are installed in steering systems on the basis of the so-called steering trapeze and gear reducer. This type of steering is mainly used in the SUVs and old rear-wheel-drive models. Steering gear with hinged connections is used in the steering gear. The steering gear is used in the vast majority of the front-wheel-drive vehicles. In general, the draught shall be made composite in order to provide for the possibility of adjustment. Irrespective of the design of the steering control, the end elements of the steering control shall be of short joints with hinge at the end. They are called arrowheads or helmsman. The carving at the other end of the tip is used to adjust the ascent of the wheels of the motor vehicle. Structural peculiarities of the steering nozzle

Structural peculiarities of the steering nozzle

Depending on the model of the vehicle, the wheelhouse may be different in length and shape. The tip of the tip may be straight or curved in the horizontal or vertical plane. In the case of a bend in a horizontal plane, the arrowheads that transmit the force to the right and left turning fiends are different. The boatmen shall, in general, be connected to the steering by a rethreaded adjustment function.

The hinge of the tip of the helmsman consists of a movable helmsman, a hermit, liners, a puck and a spring. The thumb for the hinged finger is the helmsman's own head, which is at the end of the thickening method obtained by the casting method. The arrowheads are both served and non-serviced. The supported arrowheads are distinguished by the tank-plate, which is mounted with a periodic grease syringe.

The tip can be structurally executed as a sidebor knot or unlatched with a cap tip.

In the broken gear, the bottom cover of the shell may be threaded or locked by a lock. In recent years, the latrine arrowheads have hardly met since they are noticeably giving way to safety.

The left finger may be either a cast or a cold volumetric stamping technique with special steel, which increases its strength many times. Special heat treatment is given to give extra strength after casting.

The steering tips pass through the mandatory ultrasonic test, excluding possible manufacturing defects and fractures of the finger or shell.

The ball part of the finger is carefully slicer to achieve the highest purity grade. The helmsman's insertion shall be made of an anti-friction material resistant material which shall guarantee the long-term operation. The connection can be made with a bookmark of grease for the entire life of the nozzle, or without lubrication when the liner itself has lubricating properties.

The body of the nozzle is made by a method of casting under pressure to obtain the details of the toughness. For comparison, the same method produces the loaded detail as the split.

The enclosure is subjected to special treatment by the anodizing method to give it corrosion resistance.

Special features of steering rods

The quality and condition of the steering gear shall be given special attention, as it loses the connection between the steering and the wheel, which is completely unacceptable during traffic.

During the operation, the tip shall be subjected to a constant load. The various forces are acting on it from all sides. Therefore, the tips should be examined regularly.

A short list of the symptoms of the potential wear of the steering gear: the beating of the steering wheel, the increase in the free movement of the rudder (so-called luft), the change in steering control efforts, etc.

Often the cause of the malfunction is the bursting of the duster and exposure to the jointed water and mud connection. The scab gradually goes out through the hole in the duster and washed away with water, and the dirt, when it comes to the joint, begins to act as an abraking, repeatedly reducing the node's resource.

Protective leather may be made of both frost-resistant rubber with good elasticity and specially designed polymeric compounds.

After finding a violation of the integrity of the protective cover, the fault must be corrected immediately, replacing the duster without having to wait for the details.

In case of removal of the steering nozzle for replacement or replacement, a test of the manufacturer's ascent and the wheel scatting shall be carried out after it has been installed, as the post-disassembly and assembly configuration is lost. The restoration of geometry is carried out in points of assembly, equipped with a special stand.