History of appearance

The first brake systems were used in a buzz transport. They were like the primitive predecessors of bicycle-boat brakes. But it has been a long time since then, and the mechanisms for stopping transport have been seriously evolving. It is no secret that the biggest leap in the development of the brake systems was made at the dawn of the automotive industry. At about the same time, both disc and drum brakes were invented. Drum brakes have been particularly distributed.

However, the first drum brakes were very worn. The boats were iron and the mechanisms had to be constantly adjusted when worn out. Later, the brake pads were made from asbestos-resistant abrasive abrasive material, but this was not resolved until the end of the problem. And only in the early ' 50s, with the invention of self-regulating drum brakes, the constant headaches with the adjustment of the mechanism have gone into the past. Since the mid-60s, many automakers have gradually started to install drum brakes on the rear wheels of cars only, and the front wheels were equipped with disc. Without major changes, drum brakes have been and are still in use.

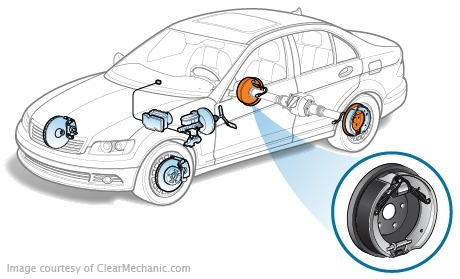

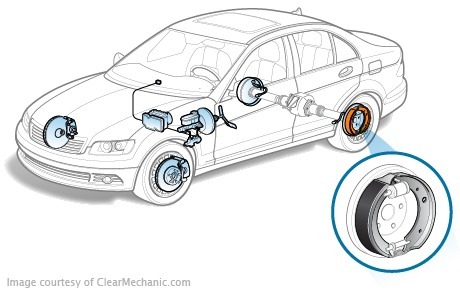

Device

The drum brake consists of a rotating drum and pad that is pressed against the drum and brake. Naturally, the pads are located within the floor of the brake drum. The movement of the pad inside the drum is performed by a spring, which shall be compressed and compressed when the brake pedal is pressed. This process is done by a brake cylinder that is pressurized to a hydraulic system and is clambering the pad to the drum. In some cases, brake cylinders may be two-duplex. The entire design is mounted on the base plate-the brake shield. There is also another form of drum brake-a band brake where a flexible metal band by means of tension pushes the brake drum. Today, the tape brake is not used in the automotive industry.

The pros and cons. Operational issues

One of the main advantages of drum brakes is that they are well protected from environmental effects and are well suited for operation under harsh conditions. Their beads and mechanisms are reliably protected against penetration of moisture and dust, which increases the resource. The braked brakes emit less heat, which makes it possible to use cheaper and simple brake fluids with low boiling point. One of the advantages of this design is that the braking force can be raised not only by increasing the diameter of the drum but also by its width. Thus, the patch spot of the brake drum's surface is increasing, while the improvement of the stopping properties of disc brakes is possible only by increasing the diameter of the disc itself. The same performance of the brake shall be increased at the expense of the design by rotating the drum. During braking, he seeks to infuse the pad with him by pulling them around its axis, eventually reducing the necessary brake pedal force, which can sometimes even compensate for the failure or failure of the brake amplifier.

However, the drum brakes are applied more slowly than hard disk, and they are more difficult to regulate, and they are less stable in their work. For example, if the mechanism is heated, it is possible to have a "splintering" or a serious deterioration in the braking performance of the vehicle. The use of the hand brake should be eliminated at the same time as the temperature of the shoe, as it is not uncommon for the brake drum to be used. For these reasons, most modern passenger cars do not install drum brakes. The drums remain the prerogative of either budgetary marginals, where they can stand on both sides and in combination with disk or freight transport. The same can often be seen on serious off-road vehicles designed for harsh operating conditions.