Appointment

The body of the body is a structure to which all the elements of the car are attached. It is worth noting that in addition to the carrier frame and the carrying body there is a third variant, which can be called intermediate: it is a body with an integrated frame. The scheme is now mainly used on tractors, trucks and some SUVs.

Device

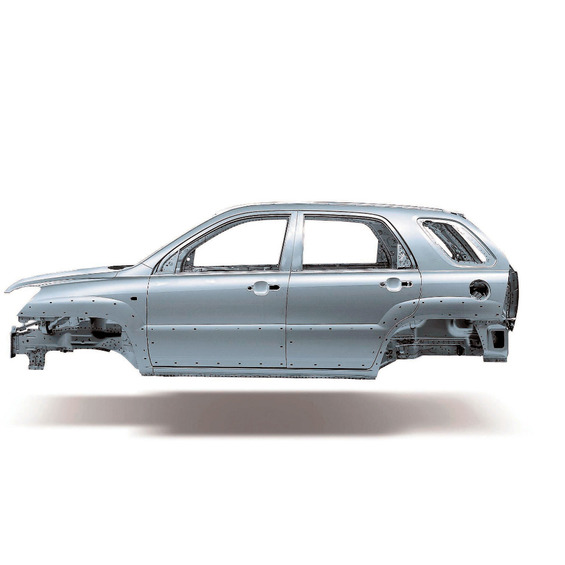

The unearable body has the toughened elements: for example, roof, rack, luggage compartment. Therefore, in terms of safety and reliability, the load-bearing bodies have the advantage over the design. All vehicles have certain requirements concerning aerodynamics and ergonomics. Therefore, the material from which the skeleton of the car is made is particularly important.

The skeleton is a force framework. It consists of a weld structure including: rack, roof, window frames, car bottom, longitudinal, reinforced beams, and so on.

For each item, its content. Dverns and floors are made of steel alloys of high strength, as well as the vertical parts of the windshield and the transverse bars that separate the passenger compartment from the trunk. The upper part of the windshield and the central racks, if any, are made of structural steel. However, the most durable of all types of steel alloys is used for the motor carcass and the beam in front of the bumpers. But the elements that do not affect passive safety, such as the outer plating, are often made of aluminum, sometimes plastic, in the production of sports cars-carbon fibre. This depends on the importance of getting rid of the extra weight of the car.

The body of the car also has the so-called deformation zones: it is a place with a reduced rigidity. They are designed to absorb impact energy in the event of an accident.

The aerodynamics of the car directly depend on the bodywork, or, more simply, to resist the air. Therefore, when working on the body formation, specialists take into account such a parameter as the coefficient of frontal resistance. For this purpose, the program is now used, in which you can virtually "vent" in the wind tunnel the 3D model of the future car. If the result is positive (and modern passenger cars have a frontal resistance ratio between 0.26 and 0.40), you can start the plasticine modelling. An interesting fact is that the manufacturer usually indicates an understated coefficient of frontal resistance is a marketing move. The permissible error is about 20 per cent.

It is the body that is responsible for the passive safety of the occupants. He is the second "protector" after the airbags and the belts. For this, the construction of the body makes several zones of different stiffness. For example, the front and rear of the vehicle are more likely to be able to absorb and absorb the energy of the impact. But the hull is more rigid, prone to deformation-to avoid traumatic situations. In order to verify the safety standards of the vehicle, special crash tests are carried out.

History

For the first time, the construction with the carrying body obtained the car of the Italian company Lancia was a model of Lancia Lambda 1922. However, her body was even though it was carrying, but it was very different from the modern one. The floor is based on the "tunnel" for the shaft of the shaft and the powerful cross-beam. The upright frames-door openings were welding. Next, the outer panels were docs, but not reinforced like modern automobils.

The idea of creating a car with such a design came into the mind of Vincenzo Lancic, under the impression of the aircraft, because they have all the elements attached directly to the fuselage.

Later, in the post-war years, the ramblers appeared in the United States, followed by "Victory" among them.