Modern cars differ from 40-and 50-year-old cars in the same way that a person is different from a dinosaur or a mammoth: they are much less "eating" and they have a better "brain". The introduction of computer management has made it possible to bring the work of many units, including the engine, to perfecting. History of computer management of the engine

History of computer management of the engine

The designers of all automobiles, without exception, were working on the task of providing the necessary amount of fuel, which is in the optimal air-to-air ratio. Since the arrival of the first car and until the end of the 70s, all their efforts have been aimed at improving the mechanical dosing system-the carburettor. The carburetor was the only possible dosing device for petrol engines within decades, and the alternative appeared only in the 1980s.

One of the first injection systems, Caproni-Fuscaldo, was equipped with Alfa Romeo 6C2500 in the mid-1950s

With the advent of cheap microprocessors, computer-controlled injection systems have won the market, rapidly replacing the carburettors. The introduction of automatics took place not immediately-first in the form of an exhaust oxygen control system, then to correct the work of the mechanical injector. The result was so compelling that the electronic circuits soon took full control of the engine.

Software development for control units

The first programs managed by the engine control units (which are also commonly referred to as the ECU. Engine control unit) was very primitive. By obtaining information from the shaft speed sensors, throttle position and intake manifold, the processor "pried" the mixture of fuel with air in an optimal aspect ratio of 1 to 14. It is this ratio that gives the most successful compromise to the completeness of the combustion and the output of the power. After the introduction of environmental standards for clean exhaust (Euro1-Euro 5), the requirements for engine management systems and the proportions of the mixture have slightly changed-the mixture for the sake of reducing emissions has had to be "oblivion" (1 to 15 and above).

"The ideal" composition of the fuel mix is called stoichiometric. In this word, two Greek roots are "element" and "measure"

The current engine management blocks are not only capable of controlling the fuel supply and exhaust composition, but also controlling the ignition system, adjusting the engine coolant temperature and other engine parameters. In addition, the modern engine control unit exchanges information with other electronic controllers, creating a single electronic control system-a local area network within a car called the Controller area network.

How does that work?

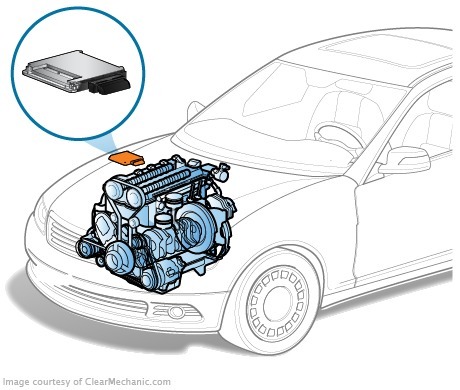

The engine control unit is a computing device whose primary function is to process input sensors from the input sensors, and the input of the control commands to different engine systems based on this information. The control block includes hardware ("iron") and software. The central part of the hardware is the processor. It flows data from all the engine sensors, and it is the engine that is being processed and analysed. The information traditionally received from the sensors (e.g. the position and speed of the crankshaft, the air flow rate, etc.) has been added the vehicle speed, the oxygen content of the exhaust gas (lambda-probe), the roughness of the road, the request for the activation of the air conditioner, and many other signals that optimize the engine work processes. The number of sensors on the current machines can be 20 or more.

The engine control block of many modern car models is connected to other controllers on the wireless network Bluetooth OBD2 Wireless Canbus

The software is necessary for the calculation, signal processing and the formation of control and correction impacts on the engine systems. The distinctive feature of modern control units is the possibility of reprogramming them. This made it possible to leave the rigid framework established by the factory programme and to open a wide path for the engine's tuning, such as the installation of turbocharger, interculling, equipment for the use of alternative fuels and much more.

The chip-tuning (modification of the engine control unit program) allows the engine to be adjusted to specific tasks, say, increase its capacity to the detriment of economy or vice versa, increase traction at low or high speed. Advantages and disadvantages

Advantages and disadvantages

Equipping vehicles with engine control units has significantly improved their performance. This was primarily reflected in the reduction of fuel consumption and the improvement of dynamic and essential characteristics. In addition, engine starting is simplified as the control unit is perfectly adapted to complex operating modes (such as engine idling or engine warm-up). With the automatic configuration of the control unit under different operating modes, the need for manual adjustment of the injection system is also no longer necessary, as each carburettor owner remembers with shudder. Finally, maintaining an optimal mix of blends reduces the amount of unburned hydrocarbons in the exhaust and therefore makes it more environmentally friendly.

Electronic engine management systems and deficiencies. The first of these is the relatively high cost of the sites. Moreover, the sites of this system are virtually unserviceable and, in the event of failure, are to be replaced. Special expensive equipment and highly qualified staff are required for diagnosis and troubleshooting of electronic systems. In addition, they have high fuel quality requirements and the reliability of the power supply.