After replacing the valves, it is necessary to do the laundry. If you install a valve without a tit, there is a risk that they will skip the air or the gasoline in a closed combustion chamber. In addition, it may also be necessary to require the old valves to be attached: the main indication that the valves are required to be attached is different compression in cylinders in which the car is moving at idle speed.

Note that before starting with the old valves, they need to be cleaned with a metal brush and then to check it with a special device.

The following tools and materials are required for the valves:

1. Immaculate pasta. There's plenty of options in the auto shops. The main characteristic of the line paste is the degree of processing. Experienced motorists advise you to take fine-grained paste, as it will be much faster and more efficient.

2. Instrument for valves. If you do not have a special tool, you can use a drill and rubber hose to make the valves available.

3. The "Sharoshka" for the valve seat. It will be necessary if the valve seat is damaged or burnt-in such a case, before tiled the valve, it is necessary to process the saddle with a "bark".

The load of valves should be carried out on the dispersed HBCD. It is implemented as follows:

1. The valve of the valve shall be placed in a circle.

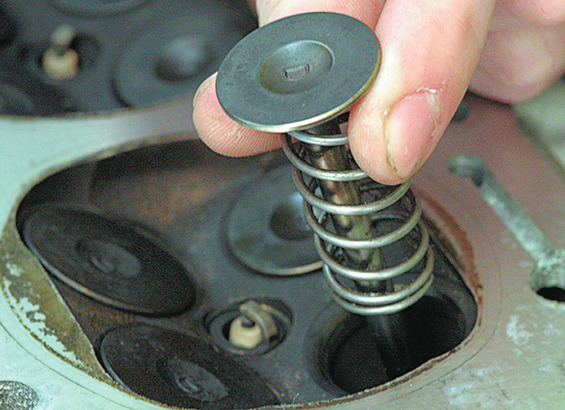

2. The valve is put on the spring, and the valve is inserted into the inlet side of the combustion chamber.

3. In order to avoid the entry of a grease grease in the rail, the grease of graphite grease should be greased beforehand.

4. A valve device is placed on the valve bar. If it's a home-made tool from the dries, pull a rubber hose.

5. Valve the valve, alternately, to the saddle, and then loosing the force. In the case of a tierke with the help of a drill, it should be turned on to the minimum speed in reverse mode, if the manual instrument is to rotate on both sides of the queue on the floor-turn.

6. The valve shall be used until a grey colour of 1.5 mm is displayed on the Fasco. At the same time, the valve seat should have a bright "belt" of the same width-about 1.5 mm.

7. After a valve seat and a valve seat, the valve should be wiped clean and run with petrol to remove the residue of the prig paste.

8. The annex shall be repeated for each valve.

After the valve is finished, a leakproofness test may be checked. To do this, a valve with springs and suhars must be put in place, and the head is put on its side and the kerosene in the canal is closed. After that, wait a few minutes: if the kerosene is not supplied to the combustion chamber, it means that the valve is hermetically sealed.