Many of the current motorists started their driving experience with the detic of the Soviet car industry: one hand had grandparent Moskvich, the other was his father's "Kopyka". Accordingly, such motorists remember these heavy, as if they were hard, rudders, for which an insouthernmost effort was required. However, those who started driving in the twenty-first century do not have such sacral knowledge, because they often went to the invariable ones with comfortable steering. The size of modern "bark" does not go to any comparison with the "mill wheels" of Soviet cars!

All of these changes were made possible by revolutionary technology, such as the steering wheel, which took on all the hard work. Thanks to the GRM, it was possible to reduce the ratio of the steering wheel and significantly reduce the diameter of the steering wheel. In addition, a motor vehicle equipped with a hydraulic steering system is considered to be safer in the direction of control.

The idea of creating a hydro-amplifier belongs to an engineer named Frederick Lanchester. He was the one who patented it in 1902. However, for the first time, one of the employees of the car company, Pierce-Arrow Francis, was to live. Davis. The first vehicles, which received a hydraulic steering wheel, were the trucks and fire engines, which were manufactured by Pierce-Arrow.

The first car with a hydraulic amplifier was the Rolls-Royse Phantom, which started in North America in the mid-20s. The manufacturer's plans to introduce this technology were extensive, but only one test sample was produced. Mass production was not possible because of the need to invest more money in this case.

The second life of the hydro-amplifier won in World War II: the American and British armies set it on heavy armored vehicles to improve their manageability. After the war, the technology went into the series: in the ' 50s, it was used on American cars Chrysler Imperial, and in Europe, the power-amplifier was equipped with Citroen DS19.

To date, there are several varieties of the GRM, all of which are an advanced version of the conventional hydro-amplifier, which has one obvious problem. It is called an "empty steering wheel" and is characteristic of a moving car in such a condition that the rudder becomes uncomfortable, so often it is difficult for the driver to calculate the angle necessary to change the direction of rotation. The "empty rudder" problem was solved by the advent of the electric power amplifier, which received an electronic control unit and a valve with an electric power train. The power amplifier, which works only with electricity, is also widely available at the moment.

Device and operating principle of the steering hydroamplifier

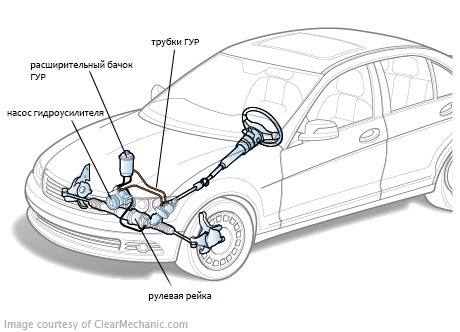

As is known, there are several types of steering equipment, but the most frequent use of the steering equipment is the use of wrenches. The hydraulic amplifier system in this case includes a working cylinder, oil pump, gold-plating reservoir, a reservoir (tank) with a working liquid, and also the fellings that connect them together. The pump shall be used to create and maintain the pressure in the system and, respectively, to ensure circulation of the fluid.

A valve consisting of a gold-flap (two cylindrical parts with oil-channels) and a peat (metal rod, which is curled by the torque), shall direct the working liquid to the necessary cavity of the power cylinder and shall return it to the tank.

When a car is standing or moving in a straight line, the rudder is unwielde, and hence the GRM is not functioning. At this time the fluid is pummkin through the balancer. When the rudder is rotated, the tornet begins to rotate and the inner part of the valve starts to spin. As the outer part remains stationary, the channel is combined and the liquid enters the appropriate cylinder cavity. The liquid dries back into the reservoir from the other cavity. Accordingly, the greater the steering angle, the greater the outlet. Thus, the distributor monitors the steering forces with the help of a torion and helps to turn the wheels.

Pros and cons of steering wheel

Undoubtedly, the main plus the GRM is to improve the driveability of the car, reduce the effort that is being spent on the steering wheel. It also reduces the load on the steering control, reducing the impact of the impact on the road surface.

The main shortcomings of the hydro-amplifier can be attributed to the loss of informativeness, which suffers from vehicles with the GRM. For many years, the engineers of the leading automakers have been fighting to improve the system, making it both comfortable in operation and informative.

Operational issues

There are several rules for the operation of the steering hydrops to be followed in order to avoid accidents. First, you need to control the presence of oil in the bachet. If the level of the working fluid is insufficient, it is necessary to believe that all hydraulic circuit nodes are airtight. However, the inspection shall take into account that the oil level may depend on the inclination of the vehicle or the angle of the wheels.

Secondly, the hydraulic amplifier must be replaced by one or two times a year to replace the hydraulic fluid. Some automakers in the maquila do not prescribe a replacement period, so the owners believe that this procedure is not necessary.

Third, it should be remembered that keeping the wheels in a limitless position for a long time could lead to an increase in the temperature of the oil, up to the boil, which would entail the inevitable breakage of the system and expensive repairs.

So, the steering wheel is a very useful mechanism that improves the manageability of the car and improves its security. However, he, like any other car system, has its own exploits. Only compliance with all rules ensures that this node has a long service life.