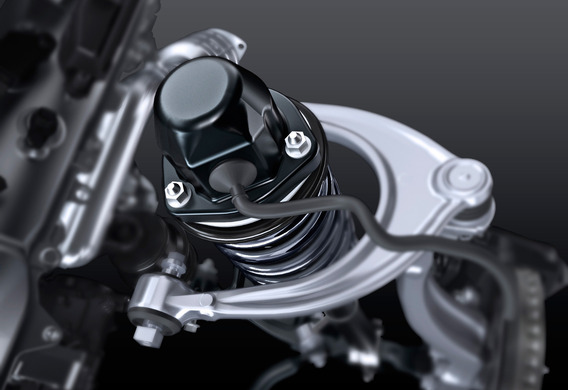

The automatic shock absorbers are designed to ensure the safety and comfort of traffic, they must prevent the wheel from the road and obstruct the movement of the body. The shock absorbers are devices that transform the energy of mechanical oscillations into heat. They shall be fitted to the body and levers of the suspension (bridge of the car) by means of elastic elements.

Various constructions

In the case of the first vehicles the mechanical friction shock absorbers were used, which were quickly worn out. Because of this, the melting of the vehicles was worsening. They were replaced by hydraulic fluid shock absorbers. In such shock absorbers, the frictional friction was replaced by the friction of the liquid through the openings. The hydraulic fracas were sufficiently compact, but they worked at high pressure levels, and were heated and short-lived. At present, the vehicle suspension is equipped with telescopic hydraulic shock absorbers.

The shock absorbers are based on the use of hydraulic resistance, which occurs when the liquid is over-wound from one cavity of the cylinder to the other through the openings blocked by the compression and recoil valves.

Most of the shock absorbers are subdivided into two groups-single-tube and double-tube. They may be oil (or hydraulic) and gasoil (hydropneumatic). The latter are called "gas" in the people.

Different types of controlled shock absorbers

In order to increase the comfort of traffic and safe driving, the vehicle is used by the electrically controlled shock absorbers.

The electrically controlled shock absorbers include shock absorbers whose characteristics are directly or indirectly altered by signals from the control unit or by the driver's request.

Depending on the principle of changing characteristics, the electron-controlled shock absorbers can be divided into several groups.

With electronic adjustment. The control unit shall regulate the characteristics of the shock absorber using the shock absorber of the electrical valves.

With magnetic adjustment. The shock absorber fluid contains metal particles. With magnetic effects on a liquid, you can change the characteristics of the shock absorber.

With the alignment of the air. In this case, the car is fitted with a pneumatic system. Each shock absorber is separately caged. The control unit or driver command changes the shock absorbers when applying or resetting the air pressure in the pneumolinia.

Hydropneumatic shock absorbers. This type means the shock absorber and the pneumoelement as a whole.

Examples of various types of electro-controlled shock absorbers

The Opel brand is set up by Continuous Damping Control (CD' s). In this case, the electronic control system changes the characteristics of the shock absorbers by means of electromagnetic valves located at the bottom of each shock absorber. As a result, the adhesive shall be significantly reduced during the braking and heeling of turnings or bumps.

The ZF Friedrichshafen AG presented a CDC system specially designed for the rear bridge of commercial vehicles. The management principle of this system is similar to the CDP from Opel.

Since 2003, Monroe has been releasing power-controlled shock absorbers. The shock absorber was designed to be trumpets: in the third tube, the oil from the working cavity is pumped into the remote reservoir with the electromagnetic valve. By changing the power of the current in the coil of the electromagnet, it is possible to increase or decrease the valve resistance and change the shock absorber.

Delphi is using MRC (Magnetic Ride Control). The main technology is the magneto-realogic liquid in the shock absorber. This liquid has a special magnetic particle size of several microns and their share is approximately 30% of the total fluid in the shock absorber. The shock absorber is built with a special electromagnet, operated by a separate controller through the wires inside the wire. When the controller generates an electric current, an electromagnetic field is created and the viscosity of the fluid changes and the shock absorber characteristics change. The positive side of this technology is the high performance of the shock absorber characteristics, the low noise of the work, the characteristics of the shock absorber can be changed fairly smoothly. The main drawback is the high cost of such a system.

The Audi magnetic ride is based on the Magnetic Ride control technology mentioned above. According to the company, the system is changing the rigidity of the shock absorbers based on the road situation.

The most striking example of hydropneumatic suspension is Citroen with Hydractive. In this system, the characteristics are changed by changing the pressure of the liquid in the pneumatic-hydraulic sectors on the shock absorbers. The system automatically adjusts the road to the road, depending on the state of the road surface and the speed of the traffic.

In the shock absorbers of Rancho, the characteristics change by changing the air pressure of the individual compressor. At the bottom of the shock absorbers are the valves connected to the compressor with a compressor. The control unit is installed in the passenger compartment and the driver may choose the rigidity of the shock absorbers.

The TEMS (Toyota Electronically Modulated Suspension) is an electronic control system for Toyota. In this case, the shock absorber shall be fitted with a mechanism associated with the adjustment rod in the shock absorber. Inside the shock absorber has several channels with different sections. By the electronic control unit signal, the switching direction of the cushioning liquid movement and the characteristics of the shock absorber shall be changed.