The target. History of appearance

Mechanical-lifts were activated by rotating the handles on the inside of the car door. And inside the door, there was a mechanism that was moving the metal support fastened to which the glass was fixed. The stack was moved along the vertical rails. At the top of it was limited by a window-seal, a bottom-damper by a dense rubber. Similar design is used in modern mechanical windows.

The electric window-lifts, which today almost drove their predecessors, were replaced by automatic. They are triggered by a switch button on the appropriate door or handrail. Electric osteers work only when ignition is on.

The device. How it works

The window-lift device consists of a actuator mechanism and a lift mechanism.

The mechanism of the drive may be, depending on the type of window-lifts, mechanical or electrical.

The mechanical actuator is the handle (the handle of the window-lift device) on the inside of the door. When this handle is spinning, there is a gear rotating inside the door.

Power-lifts have an electrical power train. This is a reverse electric motor, which is triggered by a click of a button (usually on a arm-pot)-it is wired to it. The motor has a built-in gear with a worm gear (the spinning spiral and the gears of the spiral actuating the motion). When the engine is pressed, the engine shall be started and made to rotate the gears of the actuating mechanism.

The mechanism is connected to the lifting mechanism, which is responsible for the movement of the glass.

Irrespective of the type of drive, electric or mechanical, the lifting mechanism may be three types: cable, lever, and rack.

The tall lift mechanism is a flexible element installed inside the door, usually in the form of a triangle. The base of this triangle is the vertical guide pipe. At the end of the top and bottom, two casters are reinforced: two vertices of a triangle. The cable shall be made to the third vertex-the actuated drum opposite the middle of the vertical rail of the pipe. To increase the friction on the actuating drum, several cable turns are continuously wrapped. A plate attached to the cable is moving up the vertical rail of the pipe. The plate is connected to the lower edge of the glass. When the gear wheel gear is spinning, the drive rotates and the rope on one side is wound on it and on the other the rope is rolled. The plate begins to move up or down, and the glass is lowered or raised, respectively. One of the clips is spring-loaded-it starts to work as a tener in case the cable is stretched too much. Sometimes, instead of adding a clip to the construction, they simply add a spring. If the glass pane is wide, the glass in two places is kept by the glass in two vertical rails, so the construction looks like two triangles connected at one vertex (wheel drive).

The compact rope design is perfect for small machines with large volumes inside the doors. A lack of a single-cable may, in time, be reterable, drawn or curvables, that is, the mechanism is not sufficiently durable and reliable.

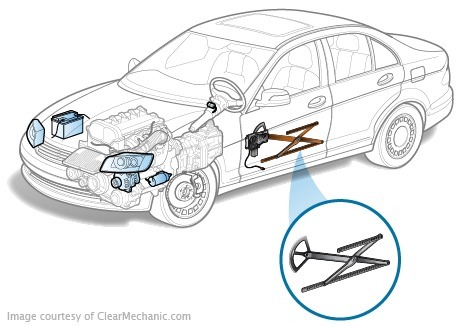

There are three types of fishing gear-one-arm, two-way, and two-wheel-wheeler.

The single-locking window-lift consists of a lever attached to the rotating gear wheel and a plate fastening to the glass. At the end of the lever, the lever, it moves the plate with the glass. The gear rotates the jagged wheel, the lever is raised and lowered, and the slider is moved along with it. The glass is starting to come up or down.

The two-track window-lift was a complicated version of the one-arm lift. It has two main levers and an additional one attached to it. The extra lever on top and bottom is equipped with creepers. The top slider, as well as the slider of the main lever, moves the plate with the glazing pane and the lower one moves on the plate fixed inside the door. Thus, the design stabilizes and decreases the probability of a skewed glass.

The two-wheel drive elevator is fitted with two jagged wheels on the right and on the left side of the gear's gears (gears hook both wheels). Each wheel has a lever with the slider. When rotating the gear on one side the levers are broken, the sliders converen to move the plate with the glass.

The fishing gear is reliable and compactness. In addition, they are very easy to mount and dismantle, and their universal design is suitable for almost all car models. The downside of the ginger-lift is the uneven movement of glass: it comes first quickly, and then everything slower and slower, sometimes with jerks.

The recovery mechanism is used less frequently than others. The vertical serrated rack, moving up and down the plate with the glass. It drives a jagged wheel mounted on a plate. The gear rotates the gear wheel, the glass pane is raised or lowered.

This installation is quite reliable because there is no cable that will lose its original strength and elasticity over time. The glass with the back window of the glass elevator rises and falls gently and gently. However, there is one restriction on the use-the rack-mounted mechanism is only possible to be installed in a large internal space, and such data does not have any vehicle.

The electric window-lifts also have a control system.

There are two types of electrical management system: simple button control or smart remote ("intelligent")when the alarm system, the alarm system and the opening/closing of windows are connected in a single chain.

Flush control is done by clicking on the convenience of the key switches.

Remote control is performed using the control panel. Among the additional possibilities of the remote control of the window-lifts are automatic opening/closing of windows, locking of switches, possibility of working with the engine shut off, auto-lowering of glass in the case of opening of a free door, as well as the inclusion of the movement in the opposite direction when an obstacle is present during closing of the window.

In order to make the hand-glass lift electric, some models simply install an electric motor (sometimes with an additional flexible drive) and combine it with an existing lift mechanism. In cars that do not require the replacement of a manual drive to an electric power, it will be necessary to completely dismantle the mechanical window-lift and make the electric. In automations, you can purchase suitable features for a particular model, including an electric drive, lifting mechanism, and equipment needed for mounting.