The gas-distribution mechanism shall ensure the intake of the air mixture into the engine cylinder and the subsequent removal of the exhaust gases from the combustion chamber.Appointment of the Gas Distribution Mechanism

Appointment of the Gas Distribution Mechanism

The GRM is one of the most complex nodes in the engine, since its task is not only to open and close groups of valves, but also to do so at a certain moment. The operation of the gas distribution mechanism is synchronized with the ignition and injection.

The transfer of the distribution shaft led to the revolutionary development of the GRM and the emergence of engines with a large number of valves per cylinder

To increase the speed, the driver presses the accelerator pedal by increasing the fuel and air flow. " Replay the increased flow of the engine can only be one way-by increasing the turnover, which means that the valves should be opened and closed more often. The engineers found a simple and elegant solution for this task, providing the GRM directly from the crankshaft. The faster the wheels turn, the more they open and close the valves, which means that the engine is able to pass through itself and burn as much air and fuel as you need to develop the desired speed.

Design of gas distribution mechanism

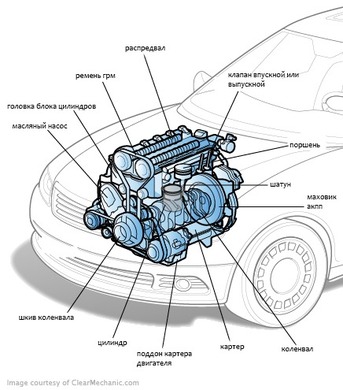

Complex tasks can only solve a complex mechanism, so the GRM consists of several groups of components. The valves open and close the intake and release channels, the gear rotates at the specified speed and the distribution shaft shall ensure that the valves are opened and closed in a timely way.

At the top of the cylinder block is the head of the cylinder block (GBV). It contains a distribution shaft, valves, pushers, or cordomsl. The transmission shaft of the distribution shaft is located outside the head of the cylinder block. For oil not to flow from under the valve cover, there is a sapper on the neck. The valve cover is mounted through a gasket resistant to oil and lubricants. The belt or chain of the GRM is put on the pulley of the distribution shaft, and is given to the gear of the gears of the crankshaft. For the tension of the belt, the roller skates are used, and for the tension of the belt-"shoes". The system normally uses two belts or belts and a chain. The belt or chain shall actuate the GRM mechanism and the second belt-additional equipment.

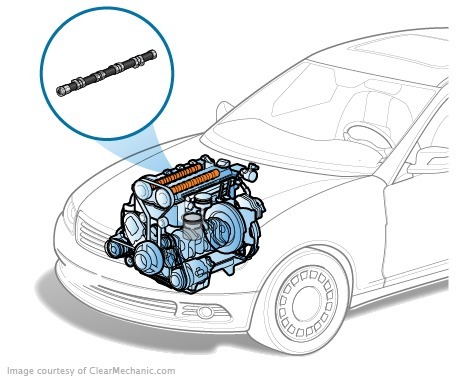

The distribution shaft is an axis with "couplings". When the shaft is rotated, the culls are in contact with the pushers of the valves at times corresponding to the cycles of the engine.

Valve group and distribution shaft

The valve unit is not only valves but also guides, springs and attachments, as well as transfer components.

The breakup or the cam shaft shall, at some point, pressure the valves or levers (rockers, cornelets and taps) that hand over the load. The mechanism shall be adjusted so that the gear ratios also include adjustment washers and bolts. In some engines, the permanent clearance is achieved by automatic adjustment with hydraulic compensators.

The main drawback of the GRM chain is too noisy work

A distribution shaft shall be driven by a harness belt or a chain. In order to transfer the energy from the crankshaft to one of the torts, the guest star or pulley, or pulley, has been fortified with a transmission belt.

The rotation of the distribution shaft in the head of the cylinder unit is ensured by bearings attached to the upper part of the GBV.

EMG with upper and lower position of valves

The gas distribution mechanisms with the upper position of the valves are equipped with almost all modern engines. This design was gradually replaced by the lower-valve in the mid-sixties, at the beginning of the race for horse power. The application of the upper-valve mechanism made it possible to get rid of the extra gear ratios. The larvesy of the valve that put the valves directly on the valves made it possible to ensure the steady operation of the engine at high speed. In addition, the valve upper position has made it easier to repair and maintain the engine. The upper position of the arrangement reduced the mass of the engine and reduced the noise level of the engine. In the end, the engineers were able to increase the number of valves (16, 24 or more) by installing two for each valve group. The only drawback of the design is the relative complexity of the actuator carried by the belt or circuit.

Types of RDTs

Irrespective of the type of drive in the work of the GRM, one important condition-the provision of the gross other relative to each other must remain unchanged. If one of the rubble starts to "fall behind," the synchronized work will be immediately disrupted.

That is why the GRM chain drive appeared before the Time-of-Time. The roller chain, collected from the same length, ensures that synchronization is best consistent.

The two main shortcomings of the chain-the noise in the operation and the difficulty of maintaining a permanent thrust have led engineers to develop the drive belt on the basis of the serrated belt. The belt has no loose coupling, but has its own, first of all, the possibility of a cliff.

Gas-distribution mechanism under control

With the advent of distributed injection and distribution of microprocessor management systems, manufacturers have had ample opportunities to attract buyers not only with the capacity of cars, but also by economy. In the process of reducing fuel consumption, the control system and the gas distribution mechanism was invented. The purpose of the system of variable gas distribution phases is to ensure the accuracy of the intake and release synchronization according to the engine operating mode. If we describe the work of this system in two words, it can be said that the rotational speed of the distribution unit in the modern engine has ceased to be constant. This is necessary to reduce the filling of cylinders with a fuel-by-air mixture when the normal volume of the mixture is almost certainly not to be fully lit. For example, if the driver is going downhill, speed is supported by the laws of physics, and in these seconds it is not necessary to bring as much fuel as necessary to move to the mountain. These dynamic changes are monitored by the VVT system, which controls the movement of the distribution unit and the opening of the valves.