The position sensor of the distribution shaft (it is still called a phase sensor) is a small but very important element in the internal combustion engine, which is responsible for the steady operation of the engine. The main function of the phase sensor is to determine the angular position of the distribution shaft at any given time. The information from the position sensor (DDSMS) is supplied to the engine control unit and is subsequently used by the controller for the correct operation of injection and ignition systems. How and how the position of the distribution shaft position (the phases sensor) works

How and how the position of the distribution shaft position (the phases sensor) works

The most commonly used vehicles are the Hall effect of the Hall effect. Phase sensor base is a permanent magnet that creates a magnetic field. The magnetic field changes its voltage when the metal tooth, which is located on the distilled disc or jagged wheel of the breakup, is closed. This change is fixed by a semiconductor, which is also in the phase sensor. The ECU shall receive signals from the sensor, read the position of the piston of the first cylinder in the ITP, and then in accordance with the engine order of the engine, the injection and ignition are provided in each.

In addition, some vehicles are fitted with a pre-defined position sensor based on the photodetector. The optical sensor reads the signal after the light is closed by the light source.

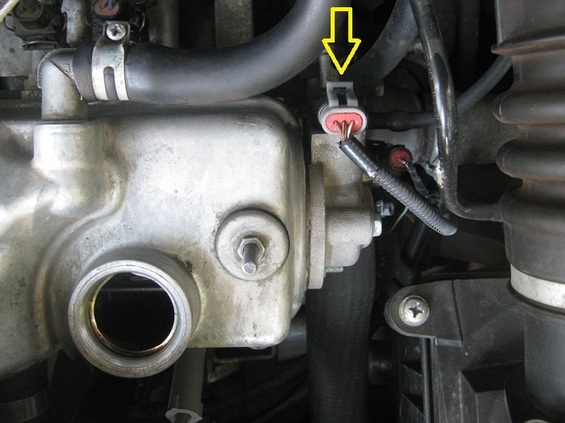

Depending on the brand and model of the vehicle, the phase sensor can be installed in different locations. The only condition necessary for the work of the DPSB is immediate proximity to the pre-crash. For example, in most Japanese automobiles, the position of the distribution walker is located in the lower part of the "lobovina" by a series of pullees. In addition, the phases may be installed in the upper part of the "lobon" near the pre-shaft.

The transducer position sensor is connected to the crankshaft position sensor. If one of the sensors fails or for some reason is unable to transmit a signal to the ECU, the controller shall read the information from the second. Phase-sensor symptoms and diagnostics

Phase-sensor symptoms and diagnostics

There can be many signs of a position sensor failure. Most often, this is the unstable work of the engine with failures, problems with launch, sudden increase in fuel consumption. In addition, the Check Engine indicator is often caught when a phase sensor is not built. If you encounter one of these symptoms, it is necessary to include the sensor validation in the Diagnostic Action List (but the rest of the sensors and systems should not be forgotten, since different "diseases" of the engine can have exactly the same "symptoms".

Very often, the position sensor is not operational due to problems in the electrical circuit. For the start of the connector and wiring the sensor should be checked for traces of corrosion or dirt (clean up if necessary).

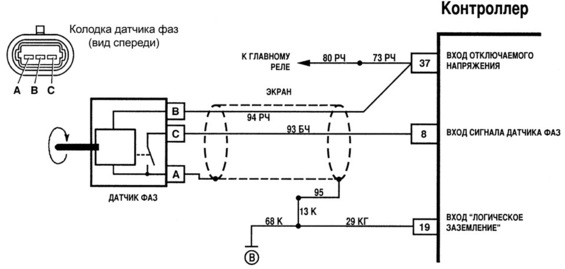

Then check the voltage in the chain by means of voltmeter. To do this, you need to check for the voltage on the wires that are going to the sensor (the ignition is on, the sensor connector is off). If there is no tension, it is likely that the cause should be found in the wrong connector or wiring. If voltage is present, the voltmeter should be connected to the signal wire and the sensor's negative power shall be negative: when the rotation is rotated, the voltage shall change. If tension doesn't change, then the sensor is dead and replaced.