History of atmospheric diesel engine

The first compression-ignition engines whose inventor name gave the name to this powertrain family saw the light in 1897. The air for the formation of the fuel-air mixture was supplied by the traditional compressor in those times, as well as in modern "atmosphere-ferniers".

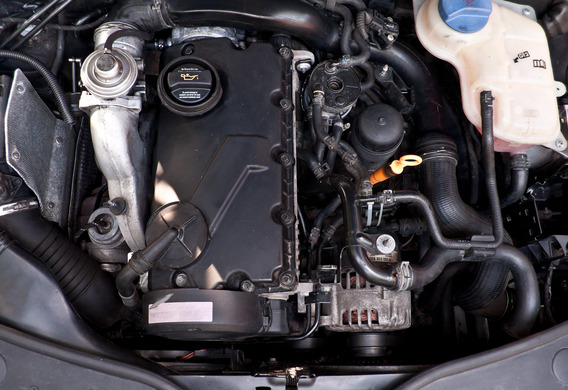

Engine and operating principle of atmospheric diesel engine

The atmospheric diesel engine is not very different from the petrol tank. The same system of cylinder piston is the cap that is transforming the extension of the burning fuel/air mixture (TBC) into the torque. The main difference of the diesel oil is in the principle of the ignition of the TBC. If the fuel is mixed with the air prior to the introduction of the cylinders and is burned by an electric spark, the diesel and the air shall enter the cylinders separately. The compression phase is air-only, with compaction heating to 700 to 900 degrees. Fuel is charged at the point of maximum compression in the cylinder at great pressure. Due to the high temperature, spontaneous combustion occurs, followed by a cycle of processes identical for all internal combustion engines-expansion and exhaust.

Types of combustion chamber of diesel engines

The absolute majority of atmospheric diesel engines differ only by the combustion chamber. In classic diesels, an undivided combustion chamber is applied-fuel is served in a supranational space. Until recently, this type of combustion chamber has been used mainly on low-negotiable engines for trucks because these diesel engines have high noise and vibration levels. However, in our time, with the introduction of high pressure fuel pumps (DDPs) with electronic control, two-stage fuel injection and stabilization of the combustion process of the fuel-air mixture, these problems on the automobile diesels practically managed to survive.

The most common in passenger cars today are diesel with separate combustion chamber-vorchamber and forcelerate. The fuel injection is not directly in the cylinder, but in the additional cell in the cylinder head, connected to it. The chamber is connected to the cylinder by a single channel so that when the air hits, the air shall be intensively curled. This improves the mixing and ignition process. Fuel and air mixture in this case ignite in two stages-the process starts in the chamber and enters the combustion chamber. Thus, the pressure in the cylinder is increasing more smoothly, thereby reducing the noise and increasing the maximum speed. Wikrekdimensional engines currently make up about 90% of this type of powertrain cars and SUVs. More complex, and the less common are forcelery diesel. The fire of the fuel-air mixture occurs in a special treading chamber, connected to the cylinder by several channels of a small section. Their shape and diameter are collected in such a way that there is a pressure drop between the cylinder and the trout, which increases the speed of the gas flow. This technology allows for a large resource, additional noise reduction and toxicity, as well as maximum alloy torque dynamics.