The gas-distribution mechanism inlet valve shall open the cylinder fuel to the cylinder and stop access before the start of the compression cycle. In the case of a diesel engine, the valve shall not be able to burn the air to the combustion chamber.

At the end of the GRM-belt, the intake valve "hangs" as the presenter stops turning. The treadles of the valves opened and the top of the cylinder

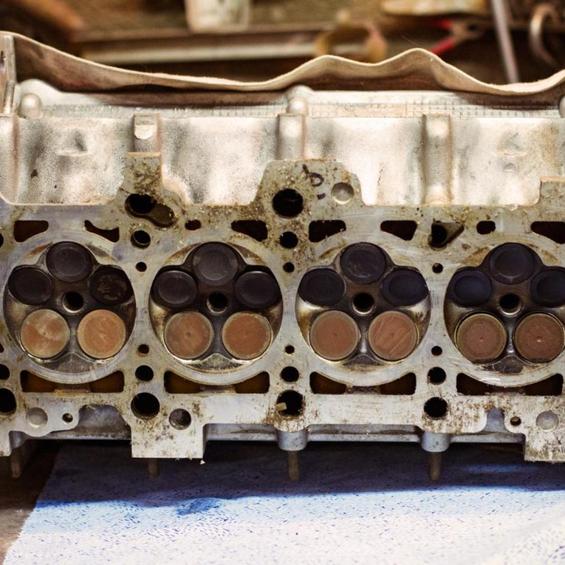

The valves shall be located at an angle between 30 and 45 degrees, relative to the vertical axis. The intake valve is bigger than the prom valve. The difference is due to the vacuum at the opening of the intake valve in the combustion chamber and at the time of release the high pressure. The pressure force is lower than the pressure, so the inlet requires a valve larger than the head to ensure the necessary volume of the air-air mixture is required.

Inlet valve device

It's a plate from a plate and a rods. A flat on the side of the combustion chamber a plate of intake valve has a conical shape from the side of the valve. When fully closed, it shall be adjacent to the "saddle" (conic) in the head of the cylinder block. The inlet valve shall be provided with an accurate landing of the inlet to which the valve in the valve is moved. It has been placed in the cylinder head and is fixed by a retaining ring.

The current trend in the construction of the GRM is the increase in the number of inlet valves per cylinder. This allows to increase the capacity of the cylinder and increase engine power

The discharge valve shall have an inner and outer cylindrical springs attached to the valve stem.

The intake valve is activated by a lever (rocker) from the grating of the distribution shaft or, in most modern engines, directly by the pressure of the fig. The spring ensures constant contact of the inlet valve with the end of the rocker or with the grating.

A gap between the wafer of the distribution shaft and the stout of the valve of the valve is formed. This makes it possible to compensate for the thermal expansion of the intake valve. The clearance shall be 0.3-0.05 mm.

The principle of the intake valve

The timely opening and closing of the intake valve shall ensure the angular position of the distribution shaft as accurately synchronized with the same angular position of the crankshaft. That is, the angular position of one is strictly in line with a certain angular position of the other.

Depending on the engine model, the intake valves may be several per cylinder.

To radically change the opening of the valves, it is necessary to purchase a set of sports

Before the piston reaches the highest dead point, the intake valve starts to open-that is, at the start of the piston, the valve is already open. For different engine models, there is a proactive valve opening. The range is 5 to 30 degrees.

The intake valve closes with some delay after the piston reaches the bottom of the dead end and starts to move up. The filling of the cylinder continues even after the beginning of the movement. This is due to inertia in the intake manifold. Characteristics of inlet valves

Characteristics of inlet valves

Of course, the most common breakage of the valves is that they must be accepted as a result of the breakage of the GRM-belt. The same thing could happen without a break if the replacement of the belt was done by a non-professional who mistakenly issued a mark on the wheel of the Kolevanwala and predicted it (or gross). Particularly dangerous are the cliffs for modern complex engines equipped with the mechanism of changing phases of gas distribution and other high-tech systems.

Another common failure of the valve inlet and exhaust valve failure. As a general rule, the problem can be identified at an early stage of reducing the capacity and cotton in the intake and venting piping, the metal knocking in the cylinder head and the fall of the engine power.

Decomposition of the coke on saddles and valves prevents them from being dense and reduces compression. As a result, engine power is also decreasing. The breakdown of the spring may cause the valve to be unpacked to the saddle and lead to the deformation of the cylinder head, the formation of sinks, or the eating of the bar. A large heat gap between the lever and the shaft of the valve also leads to a sharp metal clapping and the fall of the engine power.

Materials for the production of valves

For the manufacture of inlet valves, chrome steel is used for corrosion resistance in gas environments at temperatures above 550 ° C. This view has become quite fragile.