An engine cooling fan is a device that forces the hot start of the hot-heated engine and the radiator of the cooling system while the motor vehicle is parked. Fan role in cooling system

Fan role in cooling system

The process of evolution of the cooling system was initially followed by two main routes, so the system of two main types was found in the serial cars: air cooling and liquid (or rather hybrid). The ventilator is used in both types of cooling systems, as the end media dissipating the heat from the engine is air-dissipated. The fan is a device that provides a permanent and uniform heat transfer.

Types of engine cooling fans

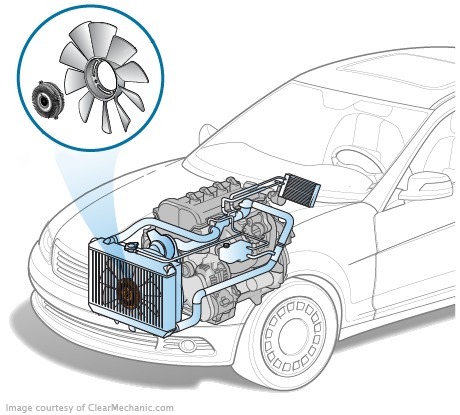

There are only two runnable fans during the development of the cooling system. The first is a mechanical fan with a belt drive from a pulley mounted on a crankshaft. In order to ensure the safety of blades at high speed, the flask of the fan is attached to the bay through the hydromechanical drive, which, depending on the design, is called a thermo or hydromuft.

Most often, the car engine is equipped with an eight-shoulder wing, although the number and shape of the blades are not regulated

This device is a variety of whiskies filled with silicone gel, changing properties under the influence of temperature. The degree of locking of the muft affects the rotation speed of the fan. When the engine is unraveling, the muct engine starts to "stuck" the rotation of the retina, which would break at a rotation speed of 3000 revolutions per minute and higher. Thermo-muff and hydraulic muff are different by design and principle of operation, but both allow for the speed of the rotation of the retina within narrow limits, allowing it to accelerate and decelerate only as much as necessary for the efficient removal of heat, and no more.

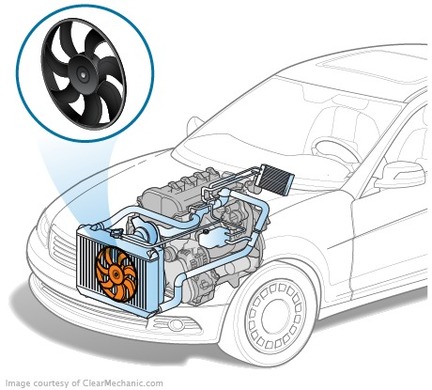

With the development of modern electronic components and the beginning of their application to control the processes in the engine, the electric fan drive appeared and quickly gained popularity. The drive consists of an electric motor and a control system that controls the cooling fan operation depending on the temperature sensor. The use of electronics has enabled the engine to be equated with a new high quality level compared to an inert "analog" system based on temples.

Engine cooling fan assembly and operating principle

Fan with whisky

Ventilators with viscous mug are rarely found in passenger cars in our time. Their application is limited to the longitudinal model of the engine, and the ease of use of the electronic control is gradually reduced by the use of electronic controls. The only segment where the installation of a fan-driven fan is preferable to serious SUVs, such as UAZ or Jeep Wrangler, designed to advance water barriers. The electronics are afraid of the water, and the temples are leakproof and will not fail after "bathing". It is filled with silicon oil, which is approximately 30 to 50 ml.

Fan with electronic control unit

A fan mechanism with an electrical power train consists of an electronic electric motor control unit, a coolant temperature sensor, an electric motor, and a fan assembly relay. In modern vehicles, two sensors are increasingly being installed, which record the temperature of the coolant. One of them is built into the tube at the outlet of the radiator, the other-to the exit from the engine or to the thermostat. In this case, the fan control occurs on the basis of the difference in the readings of the sensors.

Practically any car engine, even very old, can be fitted with a fan with an electrical power train and a thermactuator.

Other input devices are also used for control of the fan: an air flow meter and a crankshaft speed sensor. Their testimony is necessary to determine the operating mode of the motor. The signals from all sensors are transmitted to the electronic control unit which, after processing, activates the engine cooling fan relays and controls the retinal speed.

Fan with temperature switch

In older systems, the electronic control unit was missing and the electric motor power on/off function was performed by a so-called "thermoelectric switch", which is often mistaken for a temperature sensor. In fact, the "real" temperature sensor is almost always installed in the cylinder block. It is the signal to be given to the scale in the passenger compartment, as the temperature is more important than the temperature in the immediate proximity of the combustion chamber. The temperature switch also reacts to the temperature increase of the coolant (but in the heat sink). It is calibrated at a certain temperature (for example, 85 and 70 degrees Celsius) for switching on and off. If the temperature exceeds the specified threshold, the circuit breakers that end the power fan circuit are flushing inside the temperature switch. The electric motor on which the current is presented begins to rotate the retina. As soon as the temperature dropped to the low threshold, the contacts are blurred and the fan is stopping.

Operation of the engine cooling fan

The defective engine cooling fan will cause the engine coolant temperature to increase. If you notice the movement of the temperature indicator to the red zone, you can stop and independently check the health of the fan.

The electric fans shall be installed on the outer side of the heat sink and on the side of the engine compartment. There is no consensus on the advantages of an installation

To diagnose the "analog" fan, just lift up the hood and look at the elbow. The malt fan is always moving, so if you observe the rotation, the cause of the overheating is probably a failure of another component of the cooling system, for example, thermostat. The low speed fan speed may be too low for high speed fan-out.

If your machine has an electric cooling fan, and you can see that it does not work with an explicit overheating, use the following method: Disconnect the connector from the thermhole switch that is typically connected to the bottom of the cooling radiator side. Use a small piece of wire to hold the connector in a small piece of wire. The fan must be forced to work.

This method should not be recommended to the owners of the most up-to-date cars with electronic control of fan speed. The maximum that the owner can do is to check the integrity of the safety fuse. Further diagnosis is worth the trust of the professionals.