Appointment

The candle is used for internal combustion diesel engines. Its role, first of all, is to heat the air in the engine cylinder until it is launched. The candles greatly increase the power of the powertrain, saving it from excessive cold start loads in cold weather.

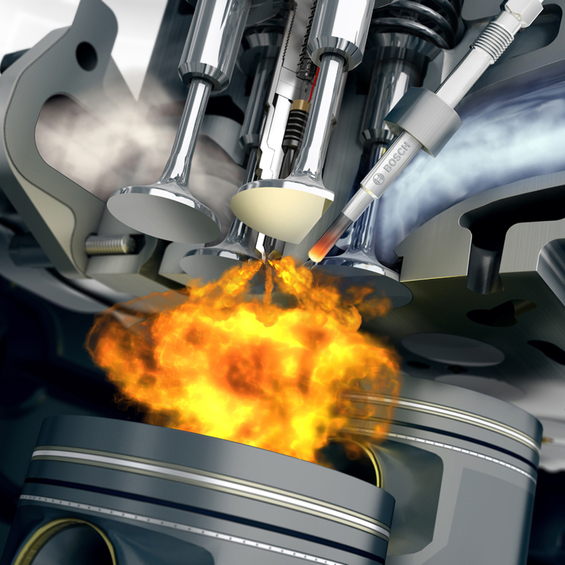

After the engine is started and warm up, the role of the light is changed-they help to dispersion the fuel. The fact is that the fuel supply through the nozzle is faced with a candle, which results in a vorutication in the combustion chamber. Thus, by candlelight, the fuel mix process is improving.

Varieties of incandations and their device

The light of the filament is like a spark plug, but it does not produce a spark plug. The candle has a heating element in the form of a spiral that can be made of metal or ceramics.

The filament lamps may be heated to a temperature of 1,350 degrees Celsius in seconds

The metal heating tip of the candle consists of two heliplets: heating and adjustment. The first one is needed for fast heating of the tip, while the other protects the candle from excessive overheating. This is due to an increase in the electrical resistance of the adjustment spiral at temperature increase.

The space between the heating tube and the spiral is filled with an insulating filler that performs two functions-the protection of the spiral from mechanical effects and efficient heat transfer. Filament lamps with metal spiral may be heated to 1,000 ° C.

The light of the filament with the ceramic heating element is similar in accordance with the principle of action. Its constructive difference is that the heating element is a spiral, and it is found in a ceramic shell. Thanks to that, the candle is getting warm-heared. Above and its capacity is 1,350 oC. Such a candle is warm in just a few seconds.

Principle of action

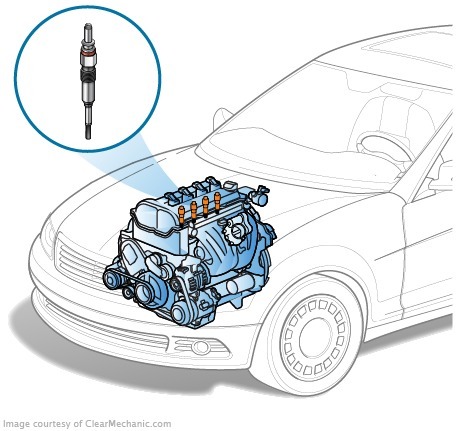

The heating element of the candle shall be located in the combustion chamber of the engine, in the place where the work blending occurs. When the key is turned on in the Start position, the light is energyhot and hot. A corresponding LED is lit on the dashboard. In order to do your job, the candle takes about five seconds. Time may vary depending on ambient air temperature.

So the candle is heated and begins to warm up the combustion chamber of the engine and the air in them. However, these few seconds are only enough to warm up the candle-heat the air and cold metal of the massive cylinder block and its head of the candle is not in a condition, especially as the air is constantly replaced by an air when the engine starts to circle.

Thus, the main purpose of heating the candles is the heating of injected fuel up to the temperature at which it will evaporate, mingle well with incoming air, and easily ignenflames from compression. After the indicator on the dashboard, the engine can be started. The indicator is usually faster than the air temperature.

In addition to pre-heating, the incandaments can provide additional heat after starting the motor, in addition to preheating

The candlelight system is either a relay or an independent electronic candle control unit. The devices regulate the voltage to be applied to the candles, the duration of heating and the temperature. The relay shall be affected by the engine coolant temperature sensor reading and the engine shaft speed sensor. These sensors are part of the engine management system.

In present-day diesel engines, in addition to preheating, the filament lamps may provide additional heat when the motor is started. This function helps to reduce the noise level of the mixture at the cold engine and reduces the harmful emissions of the exhaust gases. The pressure occurs for three to five minutes and ends when the coolant temperature reaches 20-30 °C.

Thus, the candles directly affect the operation and launch of diesel engine during the cold time of the year, and as a consequence, and on its resource.