Starter's task is to spin the engine crankshaft to make the ignition system start. The starter shall have sufficient capacity to overcome the resistance of the crankshaft mechanisms, the viscosity of the cold oil, compress the mixture in cylinders. The higher the number and length of the engine cylinder, the more powerful the starter will be needed. History of the use of starter

History of the use of starter

A close to the modern design of the starter was formed over a hundred years ago. At the earliest stage of the development of the automotive industry, the idea of a device that would allow the engine to be launched automatically was worked out in the late 19th and early twentieth centuries. Various variants of launch devices were suggested, including mechanical (as in most modern boating motors and chainsaw) and pneumatic (today aviation) types. Gradually the manufacturers came to the simplest solution-the starting handle, which is part of the coupling with the front pulley of the crankshaft. This design was successful until the middle of the seventieth years of the twentieth century as a replacement device.

The pen holder deserves to be known as the Starter Curve in Russia. On the UAZ vehicles, the possibility to start the engine with the pen remained until the beginning of the 21st century

In the early 20th century an electric actuator appeared on prestigious car models. It was first used on serial cars of Cadillac in 1912. At that time, the starter was performing at the same time the generator function, but soon two of these similar structures, but completely different devices were separated. This was facilitated by the mechanism invented by the American engineer Vincent Bendgame, which allows to force the wheel of the starter into the clutch of the flywheel and automatically pick them up when the engine starts. Soon the electromagnetic relay was invented, which automating and winding down the wheel of the starter to the flywheel. After this, the differences among the starters of different generations of automobiles differ only in the layout and the materials used.

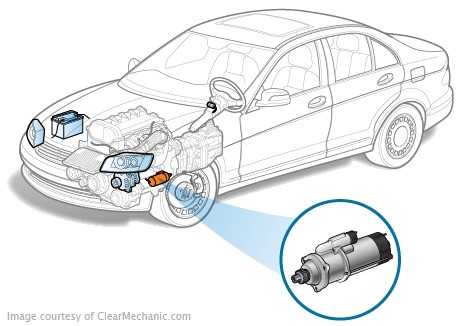

Starter Unit and Principle

The most massive element of the starter is the crust with the shaft, it is the rotor of the electric motor, centered on the bearings. The Stator is the case of the starter with the four brushes fixed on it in contact with the manifolding unit in the rear of the anchor. A retractored drive with a gear (bendix), which is rotating at the moment of the engine flywheel, is mounted on the shaft (s). The lever is connected to the traction relay.

At the start of the battery voltage (for example, when the ignition switch is turned on) the traction relay works first, with the lever running up to the moment of the clutch of the gears with the flywheel. At this point, the circuits between the chain connecting the battery to the start of the starter shall be closed. A magnetic field that produces electromotive force occurs in the brush. The crust begins to spin, and its rotation through the transmission and the toothed crown of the flywheel is passed on to the knee.

As soon as the speed of the flywheel becomes higher than the speed of rotation of the starter's anchor, the special obona coupling breaks the coupling of the bendix with the flywheel, thereby preventing damage to the starter.

Advantage and disadvantages of starter

The weakest point of the starter is a bristle knot. If there are problems in the power supply chain of the starter, the poor quality of the fuel-air mixture and the severe wear of the details of the cryoposi-tunic mechanism, the starter load is increasing. As a result, there is an increase in the current in the chain, leading to the formation of arc-discharge both between the brush and the collector and the traction relay. This results in the burnout of the collector and the relay contacts. In case of prolonged scrolling (often in the cold, with increased viscosity of oil) the temperature of the hull is increased, which, first of all, causes an increased wear on the tulles. When the tulk is out, the shaft of the anchor is vibrating, smashing the mechanism of the transmission and the killing of the flywheel crown.

If the engine equipped with a manual gearbox does not start, the starter can be used to advance the vehicle by a few metres by turning on the first or the first gear

In order to avoid this type of damage, the specialists recommend that the starter should be no more than 5-10 s, the pause before the reactivation of at least 30 seconds. If the engine does not start with a third attempt, it is necessary to find and correct the malfunction. Start with the battery status audit of the battery voltage circuit.