The GRM's Pregnant Drive has a large number of advantages and a major drawback. The main advantages of the transmission of the modern drive are imminence and simplicity. It is possible to control the tension of the flexible gear belt by means of one non-soapy device consisting of a roller and spring, it does not require numerous calming devices as for a steel roller. Another undeniable advantage of the transmission is the lack of need for lubricant. For this reason, the whole of the drive is located outside the block and the cylinder head and the easily reduced plastic cover. As a result, the GRM-belt inspection and replacement process has been simplified to the limit. History of the transmission

History of the transmission

For the first time, the GRM was used by American engineers. It was used in the engine of a sports car, Devin Sports Car, participating in the Sports Car Club of America (SCCA) championship in 1956.

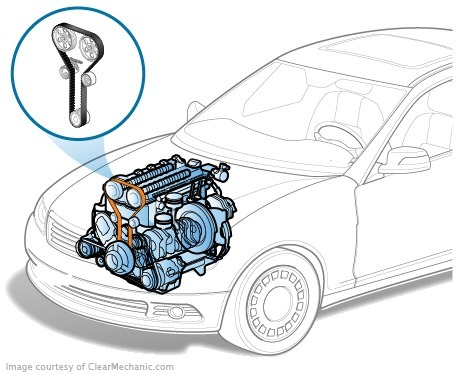

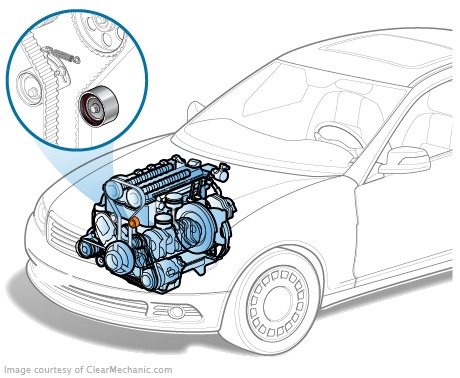

Time-to-drive design

The pregnant drive consists of a gear-type pulley, similar to the type and construction of a pulsated pulley of a distribution shaft (or two gross), a GRM-belt, a drawing-roller (sometimes combined with an additional parasitic rollers or rollers), a pulley of pump of the coolant pump. Some manufacturers prefer to drive the pump through the normal drive belt. In this case, the GRM construction is simplified.

The GRM-based belt and its teeth are often made of different materials

The GRM is compulsially equipped with a force framework that will almost completely prevent its sprain. Due to the residual elasticity of the belt and the minimum clearance gap, the GRM mechanism is significantly reduced. The teeth of the belt shall be of high accuracy.

Material and shape of the ring-belt

The shape of the profile of the teeth of the belt is three types. The trapezoic form of the oarer is standard. If high gear is required for high torque transmission, the rounded teeth are used. The use of mixed-profile teeth is much less, combining the operational capabilities of the two previous species.

In order to maintain the longitudinal stability of the belt, the blade shall be coated with glass fibre. The transverse flexibility of the belt is maintained. The belt around the seat belt is made of synthetic neoprene rubber. This protects the cords from dirt and oil and prevents premature wear. The teeth of the belt are also made of neoprenal. They are welding to the upper neoprene layer of coating. The teeth provide a free-form transfer and optimal chaining between the seatbelt and roller rollers.

Characteristics of the GRM straps

Characteristics of the GRM straps

The most common failure of the GRM straps is belt-edge. If this happened, the crankshaft continued to move and the switchboard stopped. The pistons, rigidly coupled with the wheel, continue to move up and down, and the valves remain in the same position and some of them may be open. Income to the top of the dead point, the cylinders, hit the plates of open valves, declating them and skulking.

The probability of a valve shock in eight valve engines is less than in complex systems with 16 or more valves

In simple constructions of the GRM with one break and two valves on the cylinder at the edge of the seat belt, the valves generally do not hit the valves of the valves, and the cylinders at the bottom of the cylinder. The reason is that the manufacturer is able to implement mechanical protection against damage in the head design of the cylinder block. In other words, the valve is located in the "ceiling" of the combustion chamber so that even in the open position the plates do not reach the cylinder surface. In systems with large numbers of valves per cylinder, this principle is not always implemented due to spatial limitations.

How do we secure the engine from the GRM cliffs?

To avoid such breakdowns, the belt drive belt must be modified according to the manufacturer's recommendations. The normal life of the drive belt is 60 to 80 000 km, although there have recently been seatbelts whose performance includes a guarantee of 100 to 150,000 km.

The replacement of the GRM harness belt requires professionalism, skills and knowledge consisting of a crankshaft and distribution shaft relative to each other, the tensioning of the belt, etc. The replacement of the GRM-belt is one of the few operations that would be better assigned to specialists who are familiar with the specific brand and model of the car. If this is not possible, the relevant parts of the repair manual need to be carefully considered and the special tools described therein.