History of the creation of distributed injection

The first device resembling a modern fuel injection system was invented by Herbert Stewart, an English engineer and inventor, at the end of the 19th century.

The first Russian injection system for petrol engines was developed in 1916 by the constructors Mikulin and Stepkin

His ideas were further developed and upgraded by Robert Bosch and Claessy Cummins, and the construction of the diesel engine fuel system was massed by the construction of the fuel system in the twenty years. The first Russian injection system for petrol engines was developed in 1916 by the designers Mikulin and Stepchkin.

For the first time, a distributed petrol injection system was applied to an engine invented by Swedish engineer Jonas Hesselman in 1925. According to Hesselman's plan, the fuel needed to be inserted into each cylinder towards the end of the compression cycle, so that the ignition would occur just before the piston starts down. Hesselman's engine was usually run on petrol and then used for diesel or kerosene.

Direct injection of fuel into each cylinder was used in the aircraft engines Junkers, Daimler-Benz and BMW to provide the pilots with the opportunity to perform aerobatic maneuvers without the risk of stopping the engine. German aircraft engines have been using a adapted diesel injection system of Bosch. The devices were called carburettors, but the fuel was not presented with sac but with high pressure pumps.

The first serial control systems of the distributed injection were mechanical, their production in 1951, the company Bosch

The first distributed injection system, controlled by electronics, manufactured by the Italian firm Caproni-Fuscaldo installed the Alfa Romeo 6C2500 racing car in 1940. The six-cylinder engine was equipped with individual injectors.

The first serial control systems of the distributed injection were mechanical. Their production in 1951 began with Bosch. One of the first such system in 1954 was equipped with the legendary Mercedes-Benz 300 SL "Wing of the Gull". In the future, the mechanical systems began to install on the more mass models, for example, on Audi 100 cars.

The epoch of electronic control of petrol injection systems began in the eighties with the advent of cheap microprocessors. The first serial car with a microprocessor-driven electronic controller was Rambler Rebel 1957 by Nash, part of the American automotive concern AMC. The injection system was named Electrojector, and its application allowed to lift the power of the "Rebel" 8-cylinder engine by 60 hp. Types of distributed fuel injection

Types of distributed fuel injection

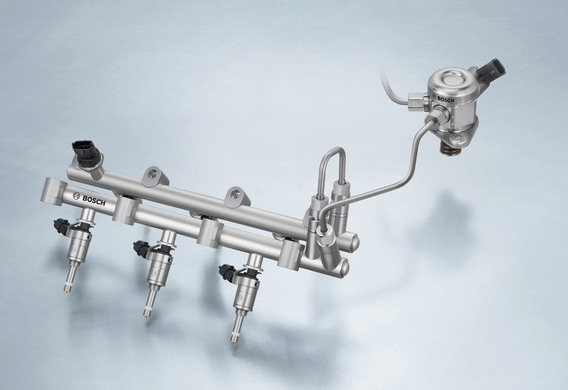

In the distributed injection system, the fuel in each cylinder is charged to a separate nozzle. There are several variants of distributed injection. They are all discolored by the opening of the nozzles. For example, in the case of simultaneous injection, all injectuahs shall be opened at once. If the nozzle opens in pairs, the injection is called the parallel.

The link between the modern distributed injection system and the carburetor was the system, with a computer managed by a single nozzle

Most modern cars are equipped with systems of phased injection. In this system, each nozzle is individually controlled and opens up to the most successful point in time, that is, immediately before the start of the injection.

In general, the fuel system of a phased injection in the control programme has two additional modes: warmed up and emergency mode. If they are activated, the phatic injection is replaced by the parallel. This allows the engine to operate during the warm-up period and at relatively high speeds. In case of failure of one of the sensors to be affected by the amount of injected fuel, uninterrupted operation of the engine under different load shall be ensured. In general, the malfunction of the main sensor on which the control unit is applied at the dosage of the fuel is the malfunction of the main sensor or the position of the distribution shaft.

The last type of distributed injection is direct injection, which is a kind of phased. In this system, the fuel is charged not to the intake manifold but directly to the combustion chamber of each cylinder.

Principle of distributed fuel injection

The control of the system of the modern car is carried out by the computer, in the car terminology, the name of the electronic control unit of the engine.

The control unit shall use the readings of the various sensors to calculate the optimum moment for opening of the fuel injectors and the time during which they should remain open.

The mass of the air entering the engine shall be measured by the mass flow sensor of the air. This is one of the most important indicators. In addition, when determining the amount of fuel, the computer shall be based on engine temperature, intake air temperature, crankshaft speed, throttle opening and opening dynamics. By calculating the amount of fuel that can be completely burned by this mass of air in cylinders, the computer signal to the nozzle at the opening. The signal is the electrical pulse of the desired duration. At the time of the signal, the nozzle remains in the open position and the fuel which is pressurized in the main line shall be charged to the intake manifold.

Plus and less distributed fuel injection

The first and main advantage of distributed fuel injection is economy. In addition, due to the more complete combustion of fuel over one cycle, vehicles with distributed injection are less harmful to the environment. In an accurate fuel dosage, the probability of unexpected failures in extreme operating modes (recovery of steep recovery, for example) has been reduced to almost zero.

The use of distributed injection has extended the lives of many popular vehicles that would be discontinued due to low fuel efficiency

The drawback of the distributed injection systems is quite complex and entirely dependent on the electronics of the design. In connection with a large number of electronic components, diagnostics and repair of distributed injection systems are possible only in the conditions of professional service center.