The motor of the car is a complex mechanism consisting of many parts. Within the engine, a variety of technical fluids, some of which are under great pressure, are circulating continuously. The engine casing shall be hermetically sealed to maintain constant pressure at the constant level and to prevent the release of the liquids. In order to ensure the leakproofness of the various forms, the various forms of the various materials shall be used. Types and designation of engine gaskets

Types and designation of engine gaskets

The shape and material from which the pad is made depends on the physical properties of the environment with which it will be in contact. Part of the linings shall be used to hold the technical liquids-engine oil and coolant in their assigned locations. Others are used to seal parts and resist internal pressure in combination with a high temperature, such as a block and cylinder head, forming a combustion chamber.

The additional advantage of the gaskets is that their application does not allow for ideal treatment of adjacent surfaces. Soft pad takes shape of detail, smoothing roughness

The third, commonly referred to as "Salnikov", compacted the place of contact of moving parts with the motionless. The exact shape of the linings depends on the configuration of the adjacent planes. Each manufacturer has the details of the unique form, so the gaskets are not harmonized and the gaskets recommended by the manufacturer must be purchased.

Stack head layout

The laying of the HBCD shall be located at the junction of the cylinder block and its head. In the area of placement of the gasket, the engine and the lubrication system are located, and the fuel is an air mixture that produces a large amount of energy during combustion. The environment is very unfavorable because constant fluctuations in temperature and pressure occur. Accordingly, to withstand such heavy loads, the gaskets are made of solid materials resistant to high temperatures.

The details we call the sappers aren't really. Seal-outdated structure from metal clips and stuffing (oil-impregnated ropes)

The materials that make the gaskets of HBOs can be divided into two groups: metal and non-metallic materials.

Non-metallic gaskets

Non-metallic gaskets are in turn divided into asbestos and asbestos. The first is made of asbestos asbestos. In general, the central holes for cylinders are reinforced with steel rings on the edge of the cutout. The same rings are fitted with holes for the charmer passing through the gasket. There is a variety of gaskets with the addition of asbestos fibres and graphite powder.

There is a white sheet of material; the gaskets formed out of it are more expensive in production, but with a higher wear resistance. It is made of synthetic fibres and rubber, which is pressed at high temperature.

Metal gaskets

The metal gaskets of HBCD are the most common type. Most of the gaskets are made of laminated steel or leaf copper. The locations, which are associated with the planes of the parts, are often covered by a rubber-like composition to ensure a reliable seal. Such gaskets, unlike non-metallic gaskets, are more wear-resistant and longer. Copper stowage is less frequent because of the high cost of the material. It should be remembered that the Nonce gasket is a non-expendable product, even if you do not see signs of damage. In the case of delay, it shall take the form of its surfaces, and it is impossible to put it 100 per cent in the same position. For this reason, every time the SBP is removed, a new gasket must be acquired.

The main reason for the premature failure of the HC gasket is to overheat the engine. If you are replacing a pad, you must correctly tighten the mounting bolts or stiletto pins. This shall be done by means of a reliable and qualitative dynamometer key and in strict accordance with the procedure described in the repair manual of the engine.

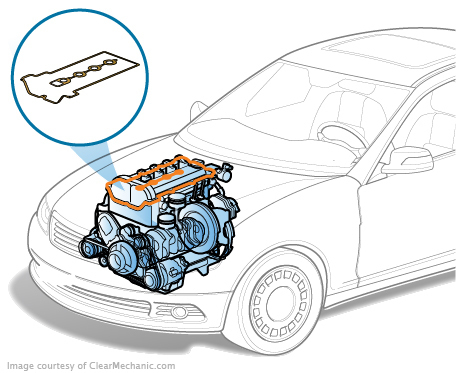

Cover for the valve cover

The valve cover is used for rubber gaskets (cork gaskets were encountered in the past). The casing of the cap seals the interface of the valve cap and the corresponding slot in the upper edge of the HBCD. It is used to protect against motorized oil leaking from the head of the unit to the GRM facility.

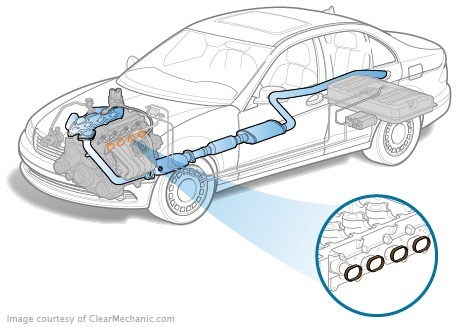

The intake and exhaust sewer pipes are compacted with pads on the junction with the cylinder block. It is easier to plot the intake manifold as it only requires constant pressure. The temperature in the collector is not increased, so the gaskets of compressed cardboard are most commonly used for compaction. The exhaust manifold stowage shall prevent the breaking out of the exhaust pipe into the subspace. The exhaust manifold is located in an elevated temperature area, so the pad shall be material that is resistant to temperature and high pressure. Metallic gaskets and gaskets are often used.

Cooling system

The operating temperature inside the cylinder block depends on the correct operation of the cooling system, and therefore the engine resource. The air circulation blower, the radiator and the coolant liquid shall be used for cooling of the engine and shall be supplied by means of a pump. gaskets are also used to ensure that no depressurization occurs at the cooling site.

The material for the heat exchanger's linings is a synthetic rubber that can withstand the effects of fluids and oils. The temperature range of the synthetic rubber: from -45 to +110 degrees. These gaskets are fitted with a water pump cover, a thermostat cover, and other surrounding parts.

Other engine design types

Due to the large number of movable parts, first and foremost, the engine has a large number of different gaskets that inhibit the permeation of the engine oil. In this category, special type-gaskets, which are used for sealing the peat (crankshaft, crankshaft and so on), should be provided. The details we call the swords are actually called the cuffs in the technical language-this is a round-shaped padding of a shaped profile, reinforced with a ring spring. The main parameter of the alarm is external and internal diameter. The outer diameter corresponds to the mounting position in the block, the inner diameter of the end part of the shaft. They make the salamers out of a solid artificial rubber, and the profiled form gives the product a stiffness.

In the kit with the gasket of many engines, there is an additional pad consisting of several rings that protect the oil from the oil well

Dozens of rubber and paronyms of different forms are used to seal the various joints in the engine. Their number is so large that often gaskets are sold with kits and straps, for example, "carburettor kit" and tp. Artificial rubber from which they are made is resistant not only to the effects of motor oil, but also to gasoline. The gaskets are not uniform in size and shape even within the line of the engines of the individual manufacturer, so only if the exact number of the part received with the help of the original catalogue and VIN of the car is known.