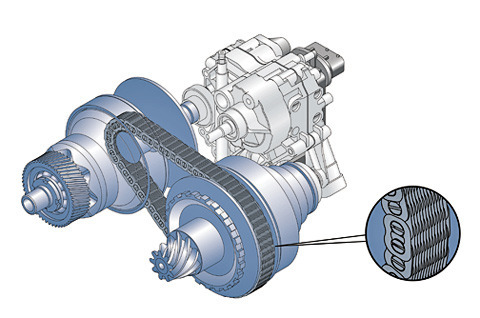

A variable-speed transmission that ensures a smooth change of gear ratio. The variator is called CVT, which means "constantly changing transmission".

The main advantage of the option is the efficient use of engine power and fuel economy. This is achieved by a smooth change of gear ratio and the maintenance of the necessary engine speed. Due to the lack of transfers, other boxes of movement of the movement are not available.

Variator is able to ensure the most smooth motion of the car

A cross-component is composed of the following components:

1. Engine connecting and depressing the engine

2. Variator

3. Backturn mechanism

4. Variation control system

The types of mechanisms that connect and disconnect the engine are as follows:

1. Automatic centrifugal clutch

2. Electrocontrolled electromagnetic clutch

3. Electroncontrolled multi-control wet grip

4. Hydrotransformer (as in ACPR)

The most common use is the torque converter, as it is tested by time and allows to connect and disconnect the variator smoothly and without ropes. This increases the resource and the variator and the engine.

The blade is equipped with one or two handholds. Two pulle' s connecting the two-seer belt. The shiva is the two cones that move and thus change the gear ratio. The belt may be made of rubber or flexible metal. Rubber belts are currently not applied because of their short-life.

The CV' s design is such that the car cannot go backwards. For this, there is a special mechanism in the transmission: a planetary reductor. A variator is managed as well as a simple APPR selector at the salon. Some of the variaans are equipped with the option of choosing fixed-uterine devices.