The speed sensor (dwindy) is installed on all modern vehicles and is used to measure the speed of the car and transmit this information to the ECU. How and where the speed sensor is located

How and where the speed sensor is located

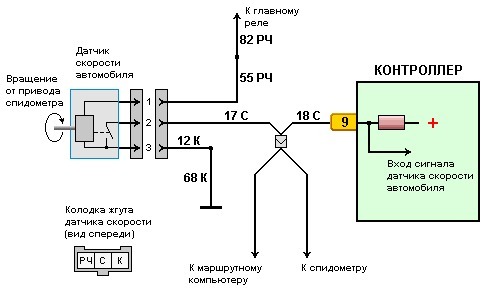

The speed sensor operation is based on the application of Hall effect: the sensor signals a frequency-pulse signal. The frequency of the pulses to be applied to the ECU is proportional to the speed at which the wheels are rotating. The engine control unit receives signals from the speed sensor, calculates the interval between the pulses and, according to this, calculates the speed of the vehicle. For every kilometre of the road, the speed sensor produces approximately 6 thousand signals.

The speed sensor is usually on a gearbox: it is located directly on the speedometer actuator. Symptoms of malfunction of the speed sensor

Symptoms of malfunction of the speed sensor

The most common sign that a speed sensor is not operational is idle speed. If the machine is stalls on idle (for gearshift or for coast-down), it is necessary to check the speed sensor. Another sign that the speed sensor is out of order is not a working or incorrectly working speedometer at all.

The problem most often lies in the edge of the chain, so the first case needs to visually examine the speed sensor and its contacts. If there are traces of corrosion or dirt, they need to be removed and the contacts cleaned and applied to them.

There are two ways to test the speed sensor: with and without removing the DCA. In both cases, a voltmeter will be required to test and diagnose the speed sensor.

First method of checking speed sensor: remove the speed sensor, determine which cell is responsible (the sensor has three terminals: grounding, voltage, pulse signal), inbound contact of the voltmeter, connect the voltmeter to the terminals of the pulsed signal, the second contact of the enclosure should be grounded on the metal part of the engine or body of the car, when the sensor is rotated, the voltage and frequency in the voltmeter must increase.

- remove the speed sensor,

- determine which cell is responsible (three terminals: grounding, voltage, pulse signal),

- The voltmeter's inbound contact is connected to a pulsed signal, the second contact of the voltmeter is grounded on the metal part of the engine or vehicle body,

- when the speed sensor is rotated (this can be adjusted to the probe axis), the voltage and frequency in the voltmeter shall be increased.

Second method of checking speed sensor: Cease the car so that one wheel does not touch the ground, connect the voltmeter with the sensor as described above, rotate the raised wheel and monitor voltage and frequency changes.

- To reduce the car, so that one wheel does not touch the ground,

- wire the voltmeter contacts with the sensor as described above,

- Roll up the raised wheel and monitor voltage and frequency changes.

Note that these methods are only valid for the speed sensor that uses the Hall effect.