One of the most common problems with the car engine is unstable idling speed or lack thereof. The management of such a car becomes a real problem when moving in dense urban traffic. Apart from the fact that the driver will be able to learn a lot of "flattering" about himself from other participants of the movement, he can create a real emergency situation.

The idling system is critical to the engine operation, starting from the engine start and ending with the motors, so it is important that attention be given to it

The idling system is critical to the operation of the engine as a whole, starting from its launch to the motors, and it is so important to pay attention to it. Experienced motorists know how the problems with carburettor and injection engines can be caused, but the main thing is how to "treat" these unpleasant automobile "diseases".

Idle systems

The early release carburettors had a dependency idle and, by design, had little or no idle traffic to their owners.

However, time, when a liter of gasoline cost nine kopecks and a bottle of mineralk 10, was over, the fuel economy became relevant. It has, in fact, contributed to the emergence of autonomous idling, introduced mainly to reduce fuel consumption.

The advent of the autonomic idling carburettor has increased the requirements for the purity of the fuel, as well as the complexity of servicing this device. The power system has been introduced to introduce filters to clean up the fuel, as their absence has directly affected the steady operation of the engine.

If the idling bolt was enough to open the throttle to a certain angle in the early carburettors, it has become more complicated. The idle speed was allocated to a separate system, with its own channels and jikelers responsible for supplying and dosing the fuel and air. In addition, an electromagnetic unit valve was introduced to operate only if there was a power supply on its winding.

The idle system has become more complex and has reduced its reliability, as any of the sores or hairs in the fuel are likely to cause power outages or even complete shutdown.

A carburetor equipped with an idle electric drive is more fuel-efficient, but less reliable in terms of the stability of the idling speed. This is due to the possible clogging of the valve in the valve at any time, as well as the power failure of the electric valve.

Unstable turnover and reasons for their occurrence

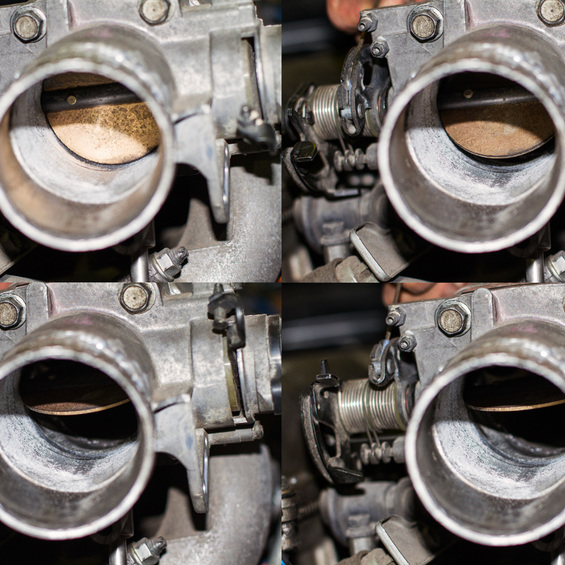

Unstable engine speeds may be caused by the eating of the throttle, mainly because of its non-return to its original position. The most common reason is the faulty mechanics of the cover-up, or in a large amount of sediment on the inner walls of the lower part of the carburetor.

In this case, the throttle controls shall be checked and the throttle shall be cleaned. The actuator's action is better to check with the assistant: it is necessary to gently press to the pedal of the gas pedal and the driver to follow the throttle control. The shale should be vertical and return without eating into the original position. If the transmission of the secondary chamber is mechanical, then the second chamber shall be opened and the layer of the secondary camera open at the end of the second chamber and then return to its original position.

When the assistant drowned to the end of the accelerator pedal, the full lever of the throttle control shall be checked and the lever arm is in the extreme position. If the lever has a stroke, it must be fully applied from the pedal gas.

When the irregular crust is observed (they are closed by ropes or do not fully return to their original position), the carburetor needs to be removed, removed, disassembled and cleaned of the throttle housing.

If the vehicle is predominantly operated in the city, then the secondary camera may be jammed at all, since most of the traffic in the city takes place in the first cell. Don't try to use force to develop it. For these purposes, there is an aerosol "carburetor clearing" aerosol, which is excellent for this work.

This tool also clears the throttle in the injection motors. In addition, it can be used without selecting a carburetor: when the air filter is removed, a small dose of flushing should be absorbed into the primary chamber while adding gas. The motor is "choked," and then it's going to be a lift. Repeat this procedure 2-3 times, you can be sure that the throttle node is improbable. However, it is better to thoroughly investigate the carburetor and wash it in detail.

Fuel injection engine

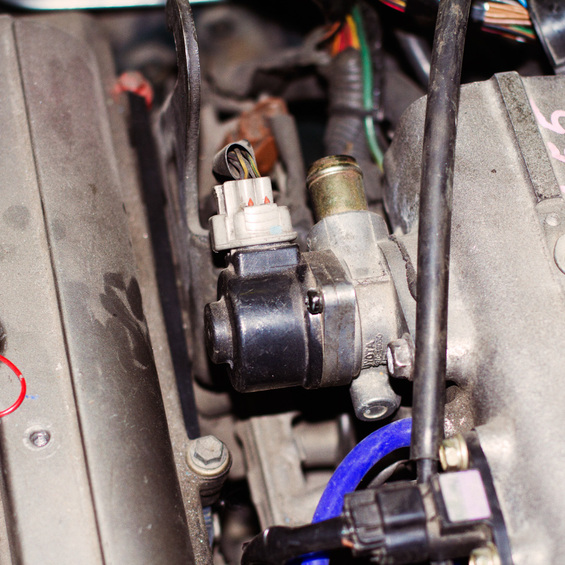

Unstable idling speed on the injection engine is in most cases related to the pollution of the throttle or extraneous air pump.

In case of pollution of the dusk (when the visual inspection shows the mud oil) its channels and the idling governor do not completely overlap with the bypass channel. The adult node is removed and purged.

In the case of an outsider, the air mass flow sensor gives incorrect data to the ECU, which adds, reduces the amount of fuel to align the ratio of the mixture. The boards, respectively, fall, then rise. The pump shall be provided with a thorough examination of the air supply channel. "Quick Start" is a solution or an emergency?

"Quick Start" is a solution or an emergency?

Unstable engine starting is caused by malfunction of either the engine itself or the life support systems of the engine, the fuel and the ignition system (with the correct battery and oil corresponding to the season).

Many of them use the quick launch vehicle, but this is only a temporary solution. They can only be used in the case of a "delay of death-like", but at the earliest opportunity it is necessary to find and eliminate the cause of the unstable launch.

The "Quick Start" feature contains a large number of readily flammable fractions and contributes to the rapid start of the engine, which is particularly effective at negative temperatures.

It is necessary to use the "Quick Start" tool as follows: not starting the engine, jumping into the intake manifold or primary carburetor camera, and then starting the engine. If necessary, repeat the procedure.

"Quick Launch" can also be used to diagnose the power system. When unstable traffic is observed, there is a need to enter the intake pipes. If the engine operation stabilizes, there is a malfunction in the power system. When the changes are not observed, the ignition system or gas distribution is defective.

Using an ether to start the engine

A diethyl ether-diethyl ether will also be used to start the engines. The ether has a high volatility and low ignition temperature (in the air mixture between 2 and 48%).

However, the ether is very covant, if using it (or using a counterfeit air), the catastrophic consequences for the engine are possible in the first seconds of launch. This is because the ether has a high speed of combustion, creating huge impact loads on all elements of the cylinder group. Its combustion is sometimes accompanied by an explosive effect, leading to instant failure of the engine parts.

In order to prevent this, additional components with lubricating, stabilizing and decreasing speed and thermal threshold of the ignition of the mixture have been introduced into the air.

If this occurs in winter, it must be taken into account that the engine must be prepared for the winter operation. When the engine starts running in summer oil in a strong cold, the engine can just "pick up" each other and then just break. Besides, the summer oil will not be able to provide the supply to all the steam in the summer oil, which will increase their wear repeatedly.

Starting with an ether-containing start aerosol is best performed by the two: one includes the ignition, and the second makes injection into the intake pipeline (pushing the gossel from the throttle) by 1-3 pausing of the sprayer, and then only the launch. This will allow to minimize the impact load at the moment of the engine start.

Theoretically, the mixture is allowed to be included in the air filter cavity, but since there have been cases of ignition, it is better to refrain from doing so.

The starting and fully resolved engine must be run on its own without the use of any launch mike at temperatures up to 35 ° C. Priority should be given to its technical condition, and the use of the launchers should only be as a last resort.